Duck mouth valve

Duckbill valves are unique, one-piece, elastomeric components that act as backflow prevention devices or one-way valves or check valves. They have elastomeric lips in the shape of a duckbill which prevent backflow and allow forward flow. The main advantage of duckbill valves over other types of one-way valves is that duckbill valves are self contained i.e. the critical sealing function is an integral part of the one piece elastomeric component as opposed to valves where a sealing element has to engage with a smooth seat surface to form a seal. Therefore duckbill valves are easily incorporated and assembled into a wide variety of devices without the hassle or problems associated with the surface finish quality of mating seats and/or complex assembly processes.

Material:

Neoprene, Heplon, butadiene rubber and ethylene propylene rubber, etc.

Application sites:

Coastal, beach, marina, reservoir, municipal flooding, sewage

-

Brand

BrandLUOYING

-

Pressure

PressureUp to1.6bar

-

Spec

SpecUp to 3000mm

-

Type

Typeone-piece

Product Range

-

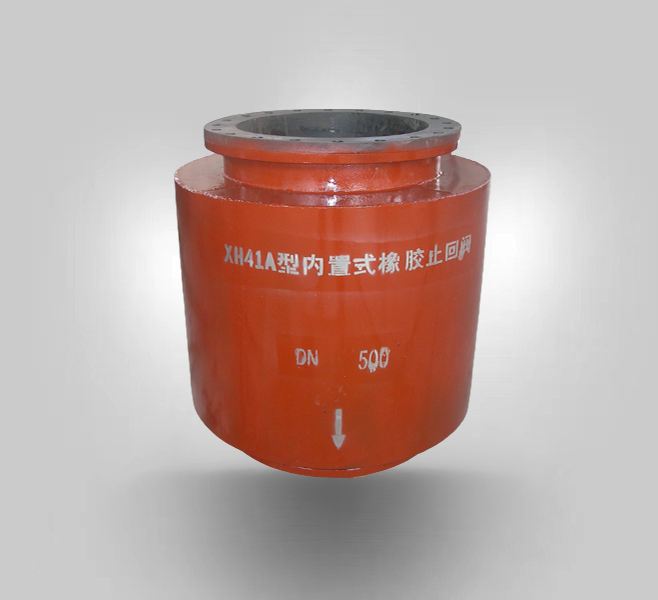

Built-in duckbill valve

The built-in duckbill valve is highly effective in wastewater systems, drainage systems, dam drainage, airport/highway drainage, wastewater tank drainage, and odour prevention.

View More

-

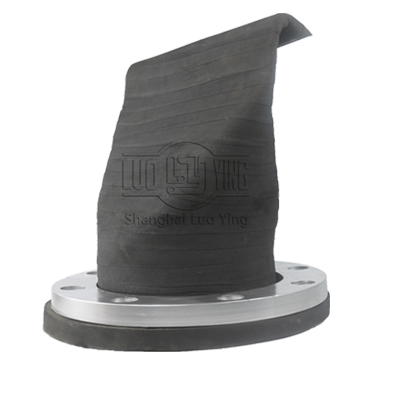

Flanged Duckbill Check Valve

Flange Rubber duckbill valves is a simple, reliable, cost effective method of backflow prevention. The series duckbill check valve is designed to be installed between two mating flanges. The simple maintenance-free elastomer with a flanged connection elim

View More

-

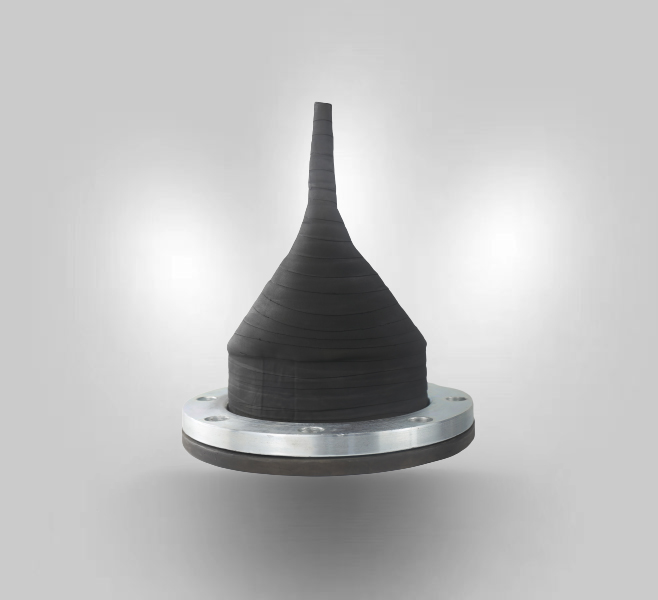

Flange Integral Duckbill Check Valve

Flange integral duckbill check valve is a simple, reliable, cost effective method of backflow prevention. The series flange integral duckbill check valve is designed to be installed between two mating flanges. The simple maintenance-free elastomer with a

View More

-

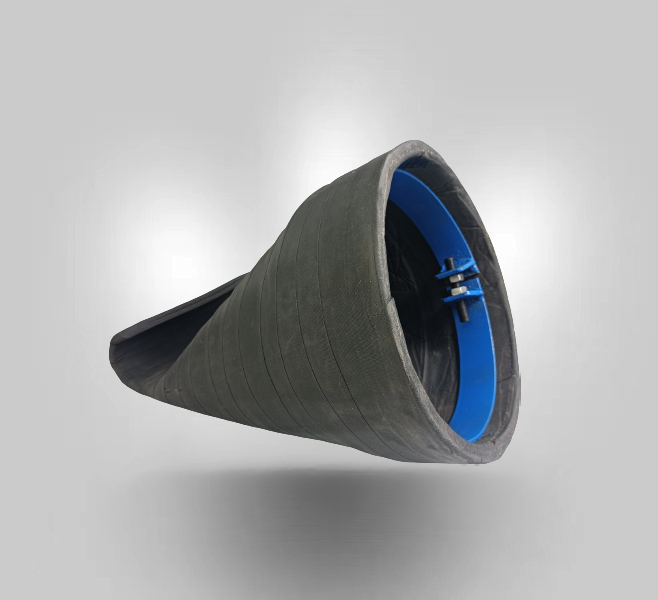

Clamp type integral duckbill check valve

LUOYING Duckbill Check Valve is reliable and cost effective flow control solution.Rubber duckbill valve for sewage made in our company have been receiving reputation not only at home but overseas.

View More

Customized Products

Technical Notes

Versatile features have made them first choice in a broad number of applicationsOther not less important features include:

Position independent,

Low opening pressure- immediate free flow,

Non-tortuous flow path,

High flow rate vs. package size,

Virtually no internal volume and dead space,

Particle compliant,

Corrosion resistant,

Wear resistant and

last but not least very cost effective.

Minivalve Duckbill valves are available in various elastomeric material, including medical and food-grade silicone and hydrocarbon-resistant fluorosilicone rubber to handle a broad range of media and temperatures.

Duckbill valves have been around for many years. Their versatile features have made them first choice in a broad number of applications:

* From long-term service in harsh environments such as in durable chemical pumps to the high-volume use in disposable intravenous fluid delivery sets.

* From one-way valves used in automotive fuel pumps to delicate valves used in tubing circuits for heart surgery, for soap dispensers, coffee makers, anti- siphoning valves in shower heads, and toys.

Advantage

Nsure that the hose meets the published levels.-

structure

100% all-rubber structure, can meet various anti-corrosion requirements (according to the actual demand, you can choose different rubber materials). -

feature

Non-clogging and good sealing.Long service life, trouble-free and maintenance-free. -

no noise

No moving parts and mechanical parts, no electric signal and manual operation, no noise. -

pressure

Opening pressure is small, greater than 0.01 meters of water head can be opened. -

head loss

Under general conditions, the head loss can be reduced to a very small degree. -

cost

Can change various installation forms to meet customer needs.Convenient installation, low cost and small running cost.

Expansion joint accessories

Quality decides value-

Flange

Piping components can be bolted together between flanges. Flanges are used to connect pipes with each other, to valves, to fittings, and to specialty items such as strainers and pressure vessels. A cover plate can be connected to create a "blind flange" Flanges are joined by bolting, and sealing is often completed with the use of gaskets or other methods. Mechanical means to mitigate effects of leaks, like spray guards or specific spray flanges, may be included. Industries where flammable, volatile, toxic or corrosive substances are being processed have greater need of special protection at flanged connections. Flange guards can provide that added level of protection to ensure safety.

-

Covers

Fasteners are used for fastening and securing materials such as wood, metal, plastic, or concrete. They include nuts and bolts, threaded rods, structural bolts, machine screws, wedge anchors, washers, rivets, and more in a variety of types and sizes, including metric and inch.

-

Particulate barriers/purge connectors

In systems that have a media with significant particulate content (i.e. flash or catalyst), a barrier of ceramic fiber can be utilized to prevent corrosion and restricted bellows flexibility resulting from the accumulation of the particulate. Purge connectors may also be utilized to perform this same function. Internal liners must also be included in the design if the expansion joint includes purge connectors or particulate barriers.

-

Liners

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.