Why do rubber expansion joints need to be reinforced with steel wire rings?

Dec-22-04

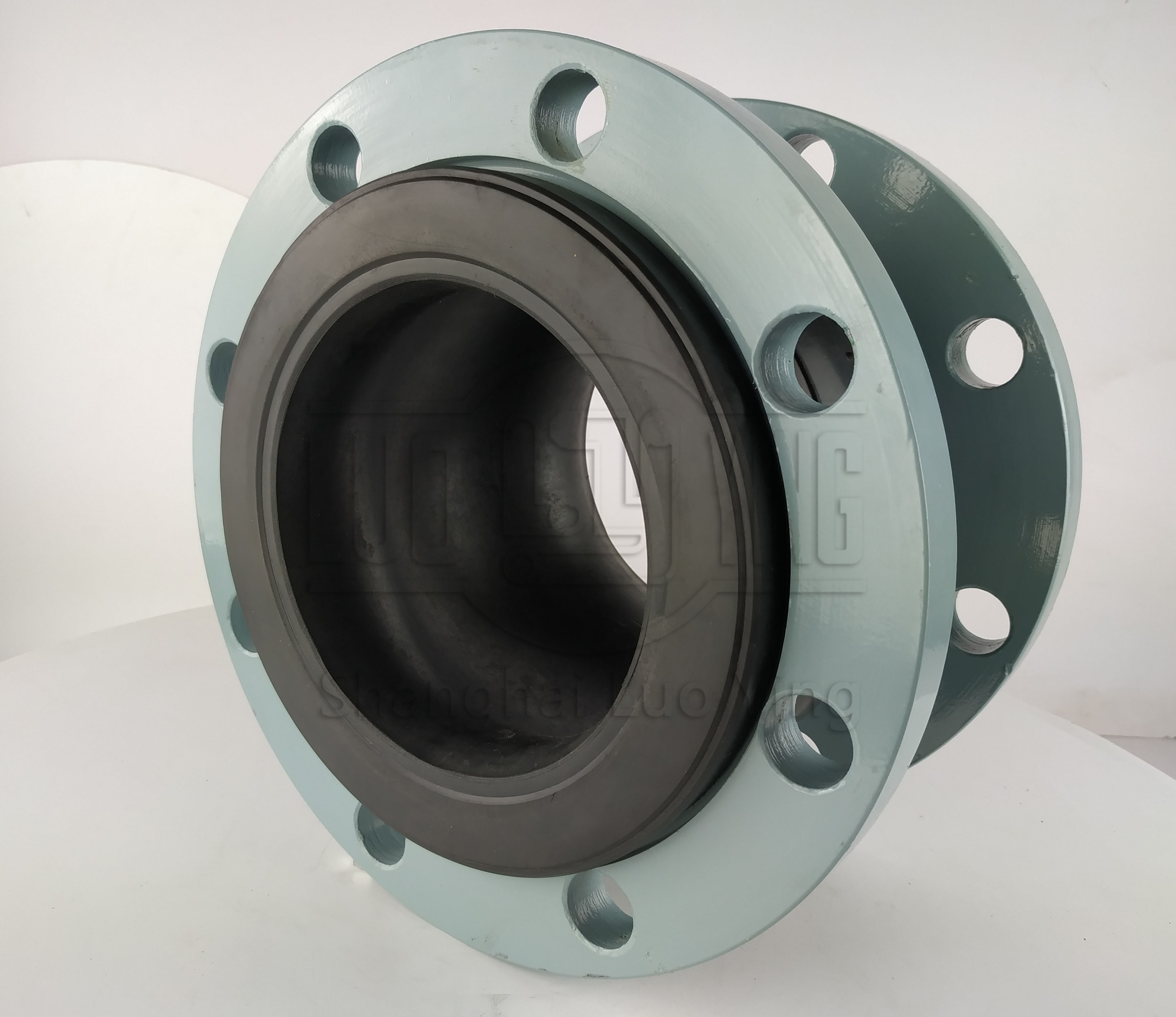

The rubber expansion joint raises the frame layer and the inner support ring to improve the tensile strength of the connecting compensator. It is importantly used in international trade of valve fittings, vacuum valves and mining extraction pipes. Compared with ordinary rubber expansion joints, it can prevent the contraction deformation of rubber expansion joints caused by negative pressure. Rubber expansion joint in the vulcanized rubber design conditions, the general rubber effect is not good or self-sulfur ineffective, too much polishing, galvanized steel wire rope rust, and even compensator position tensile strength may be particularly harmful, in the application, there are also some may randomly appear to connect the compensator part of the fracture phenomenon.After the installation of rubber expansion joints, other areas of the pipeline with random tensile bands exceeding the range of expansion joints may actually also appear cracking. Therefore, in this case, in the rubber expansion joint, the modification of the metal composite ring can scientifically and reasonably avoid the cracking of the rubber compensator in the high-pressure ecological environment, but also to overcome the defect of the relatively low pressure resistance professional capacity of the rubber expansion joint. When rubber expansion joints are used for water pump import and export, they should be located on the side of the water spring, and metal reducer joints should be installed between them and the water spring, and installed at the reducer large diameter outlet.

The use or storage of rubber expansion joint should avoid high temperature, ozone oil and acid-base environment. Outdoor or sunny pipelines should be installed with shade shelves, and exposure to sunlight, rain and wind is strictly forbidden. Painting and winding insulation materials are strictly prohibited on the surface of rubber expansion joints. Due to the aging of rubber products, they should be inspected and replaced in time. Rubber expansion joint test pressure, the exposed pipe or interface should be covered tightly with grass curtain, no interface at the pipe body should be backfilled, the test pressure is completed as soon as possible to put the water clean, do all the preparatory work before the test pressure and the test pressure after the release of water, drainage and other works.