What are the advantages of rubber expansion joints? What are all its installation requirements? What

Dec-22-04

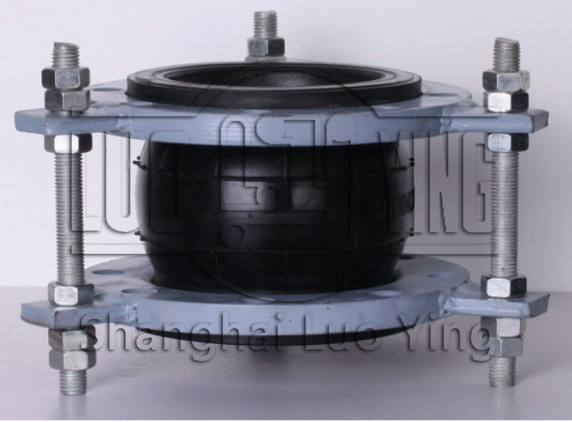

Rubber joints are also known as rubber expansion joints, rubber flexible joints, bendable rubber joints, etc. Our most common feature is that rubber expansion joints are the best solution for short installation lengths. As a result, they are able to absorb large movements and are very flexible. With a minimum face length, rubber expansion joints provide excellent movement in all directions and combinations thereof. Rubber expansion joints absorb emerging stresses and replace them with their own low stiffness. In addition, the fact that they are used to suppress vibrations and reduce noise levels allows for a reduction in pressure water hammer. In addition, rubber expansion joints are safe, reliable, durable and maintenance-free. The materials of rubber expansion joints are treated and combined to meet a wide range of actual pressure/temperature operating conditions, corrosive attack, wear and erosion. High pressure and vacuum resistance ensure suitability for a wide range of applications. It is also worth mentioning that the relatively light weight of rubber expansion joints helps reduce installation costs.For the installation of rubber joints requirements: 1, the type of rubber joints need to be checked before installation to see if the product is qualified, during installation, do not allow welding slag to splash onto the surface of the product, do not allow rubber joints to be subjected to other mechanical damage. 2, when lifting and placing rubber joints into the groove, a reliable soft belt spreader should be used, smoothly down the trench, no violent collision with the bottom and the wall of the groove. 3, flat, overhead, vertical installation When installing rubber joints, the actual working axial displacement pressure of rubber joints should be less than the supporting force of the pipeline, otherwise anti-pull-off devices should be installed to prevent pulling off under pressure at work. 4. The installation site of rubber joints should be far from heat sources, ozone areas, and the use of media that do not meet the requirements of this product is strictly prohibited. 5. Rubber joints should avoid contact with sharp metal instruments during installation to avoid puncturing the spheres.