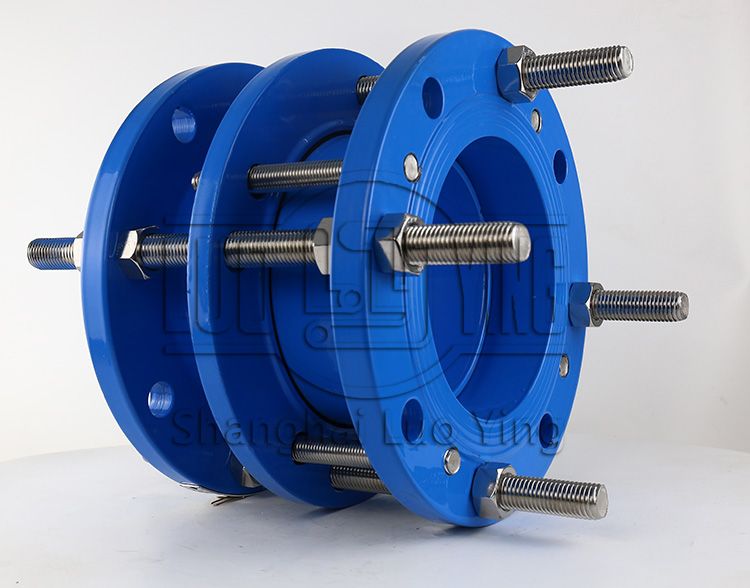

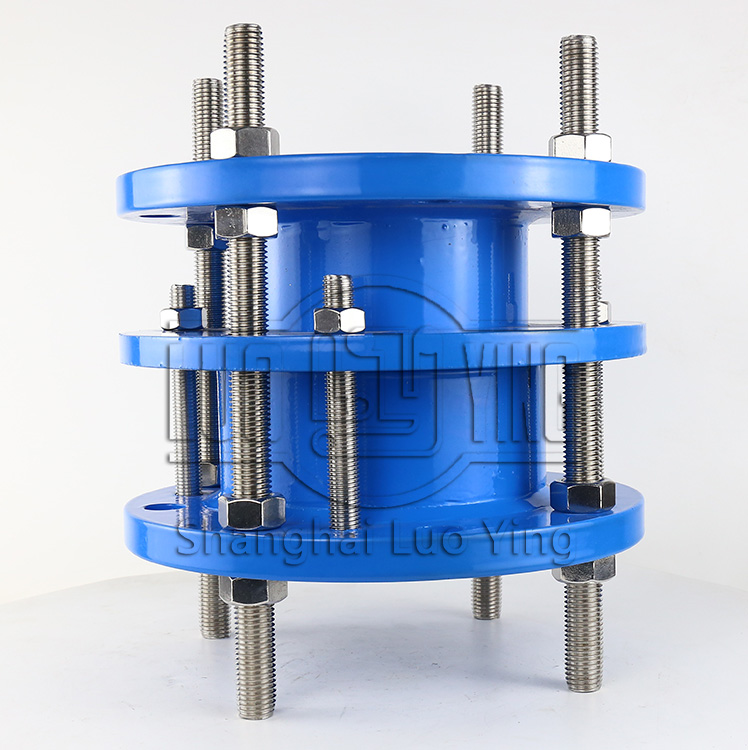

Double flange expansion joint maintenance and use

Dec-22-08

Expansion joint is a kind of product used for pipeline displacement compensation, which is generally made up of a combination of pipe joint and flange at both ends. Expansion joints need to pay attention to some matters in the process of use so as to ensure the quality of use.Check whether the expansion joint is installed correctly. When installing the expansion joint, first check whether the sealing is qualified; then put the two joints together into the expansion joint. It will expand up in this process. It is not only pressure transmission, but also displacement. The length varies according to the different types of expansion joints used. For most expansion joints, it is a simple system because it is designed according to the user's requirements. Although there is a huge space. But the joint can withstand some forces. So to make sure it is big enough to withstand this kind of load. It will also be displaced and deformed in the installation and use. But the expansion amount should be determined according to the actual needs. The expansion joint is also used to reduce the resistance when the pipe is running. Its selection is mainly based on user requirements. Therefore the expansion joint must have a large enough pipe diameter. To ensure that the pipeline is not affected by vibration.

To install the expansion joint, the installation direction and the axial dimension of the expander must be checked, otherwise the use of the expansion joint will be affected. When installing expansion joints, the same expansion length and diameter should be used. A typical expansion joint requires 10-20 mm expansion. This is the maximum diameter size for installation. Then push inward. Otherwise, it will affect the use effect and installation performance of the pipe. When there is a compensating deformation, the connecting pipe transfers the expansion through the joint to the two different directions. It has a good resistance to high temperature can be resistant to temperatures up to about 150 ℃. It will not deform under the temperature of 50-150℃. Good elasticity and has strong elasticity and good vibration damping performance.