How to use pipe expanders?

Dec-22-09

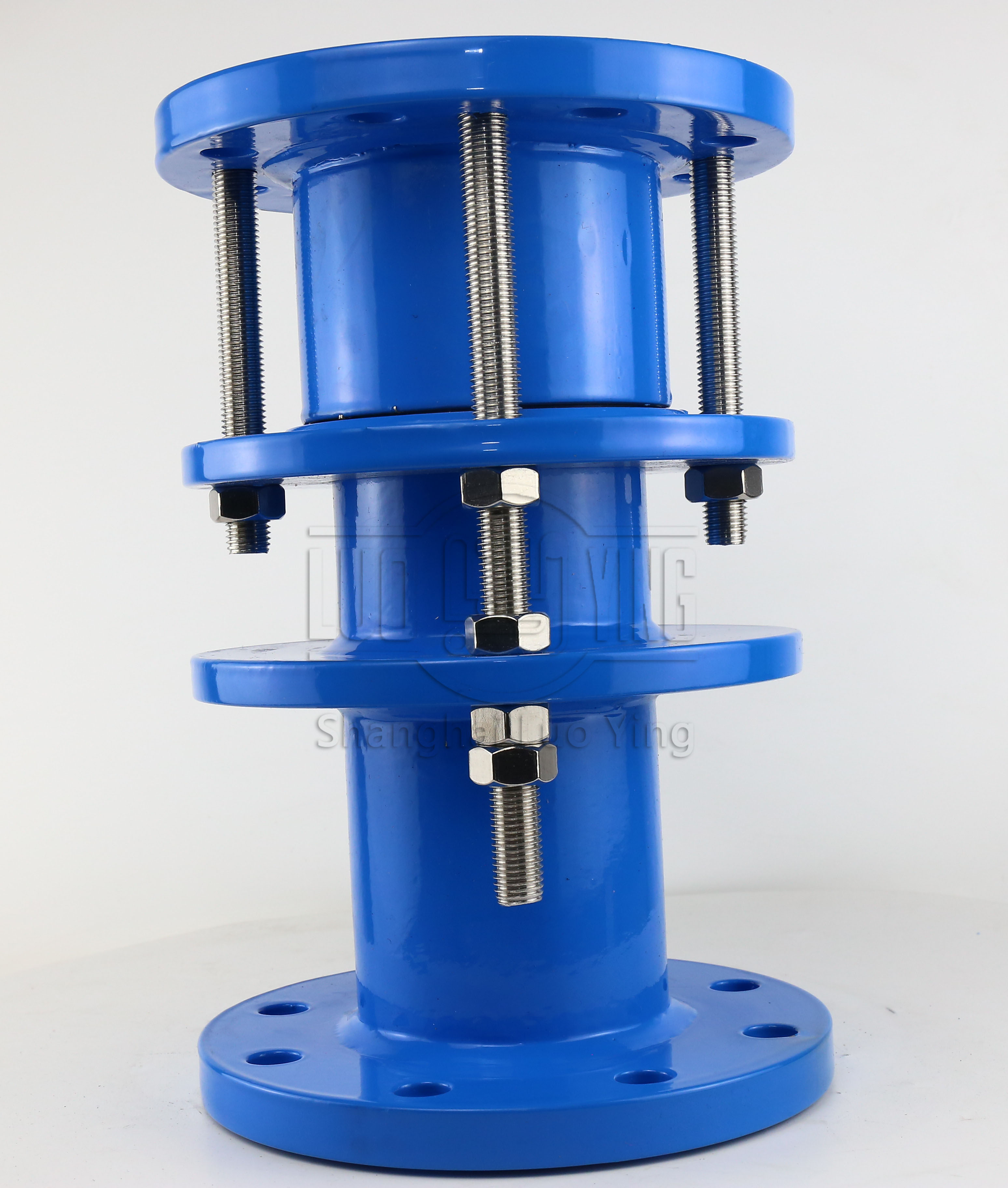

The connection of pipe expanders generally adopts bolted connection or welding. Bolt connection has the following advantages: good sealing, long service life; corrosion resistance; leak-proof, simple installation; easy installation; low price; simple and convenient installation, disassembly and maintenance. Reliable installation quality; sufficient expansion and contraction of the pipe. Wide range of application. It is mainly used for various pipeline installation to produce either large or small axial displacement and lateral displacement. It is suitable for use in various pipelines of petroleum, chemical, electric power and thermal power.The parts should be inspected for damage and deformation before installation. Before installation, check if there is any damage and leakage of each part. Before installation, check whether the expansion joint is installed correctly, the expansion of the sleeve should be compared with each other, and then check whether it is suitable. Whether the expansion is correct or not. Whether it meets the requirements. Whether it is within the allowed range when installation is required. Is there any leakage. What is the amount of displacement, etc. There is a problem when the installation is not qualified should be replaced in a timely manner. There are leaks will affect the normal work and service life.

Such expanders are suitable for general hot state or working temperature higher working conditions, for temperature changes in the use of expanders in the process of often overheating and overcooling phenomenon, so it is appropriate to use materials with better heat resistance, appropriate to reduce the amount of material. Especially at high temperatures, metal components are easily damaged by deformation and stress, making them fracture. In addition, due to thermal expansion and contraction after the displacement, so it must also be compensated. This reduces the axial, lateral and angular displacements of the pipe so that no vibration is caused and the load on the expander is reduced. In order to reduce these deformations to the stresses and displacements required for the destruction of the expansion member, the expander should have a good anti-loosening effect.