Detailed introduction related to bendable rubber flex joint

Dec-22-11

For the working environment of rubber joints, it is important to choose the right rubber products to protect the environment. For example, in the hot summer, rubber joints will not be exposed to the sun because rubber has good resistance to ultraviolet rays and oxidation. It will also reduce the oxidation of plastic and fiber, thus making the rubber have better corrosion resistance. It also has excellent resistance to ozone. It can also resist UV radiation. Therefore, the rubber joint is not affected by climate and can work or operate well in wet environments. It can also withstand large environmental loads and displacements, which is very important for severe weather. Therefore, it can withstand high temperatures, high and low temperatures and unstable chemical conditions. The rubber product is also required to have corrosion resistance and resistance to acids and alkalis. It can resist acidic and alkaline materials, chemical substances and various chemicals.Scope of application Rubber joints are suitable for connection of various pipelines, the joints can be used in various pipelines, especially for compensation of axial displacement of pipelines. It can also withstand large pressure and large displacement, it can also withstand large axial displacement. It can be used in all kinds of pipelines, industrial fields. It is also suitable for sewage treatment station, hotel, hotel, waterworks, power plant and other systems. It can also withstand large axial displacement and has good corrosion resistance.

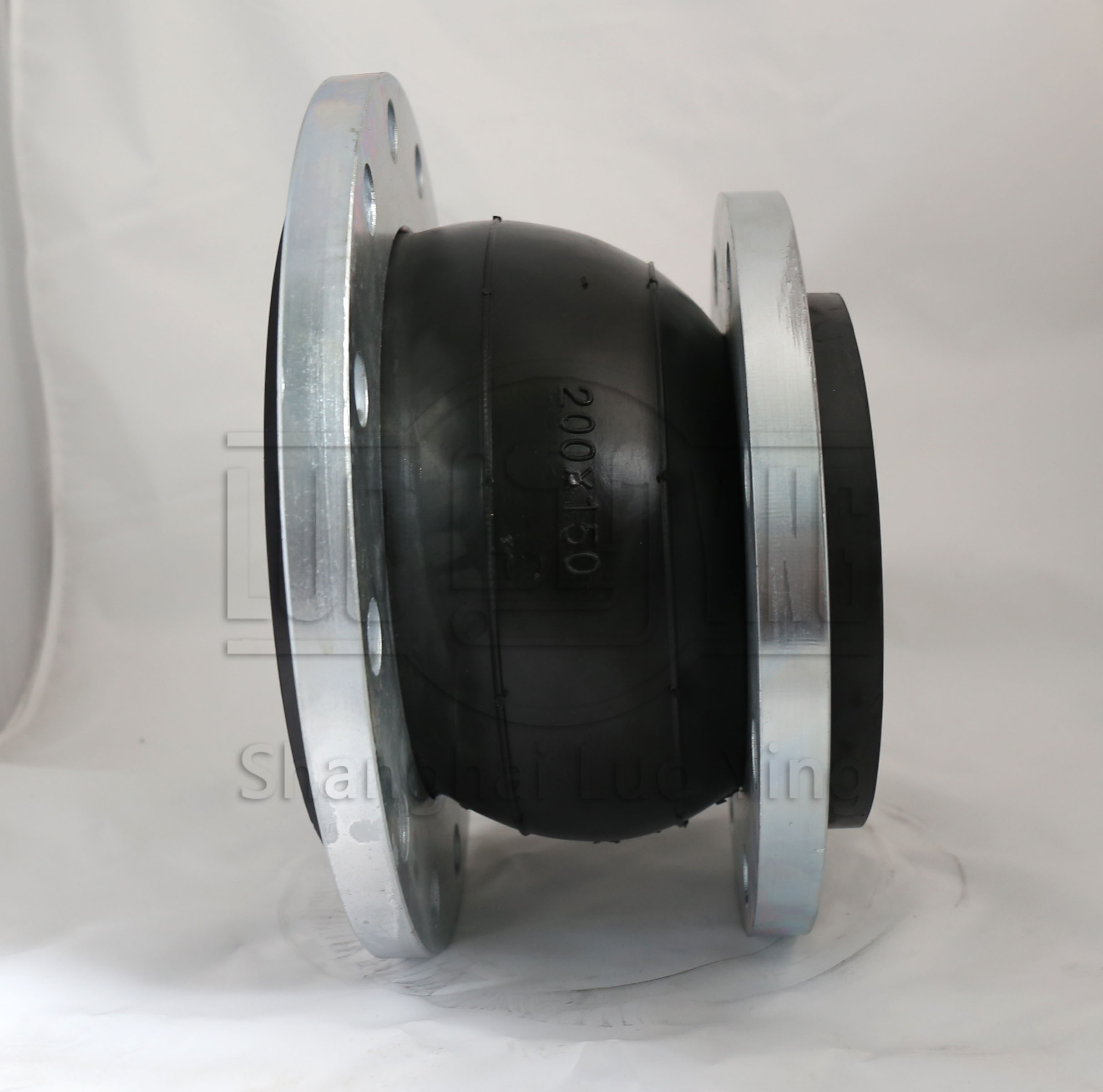

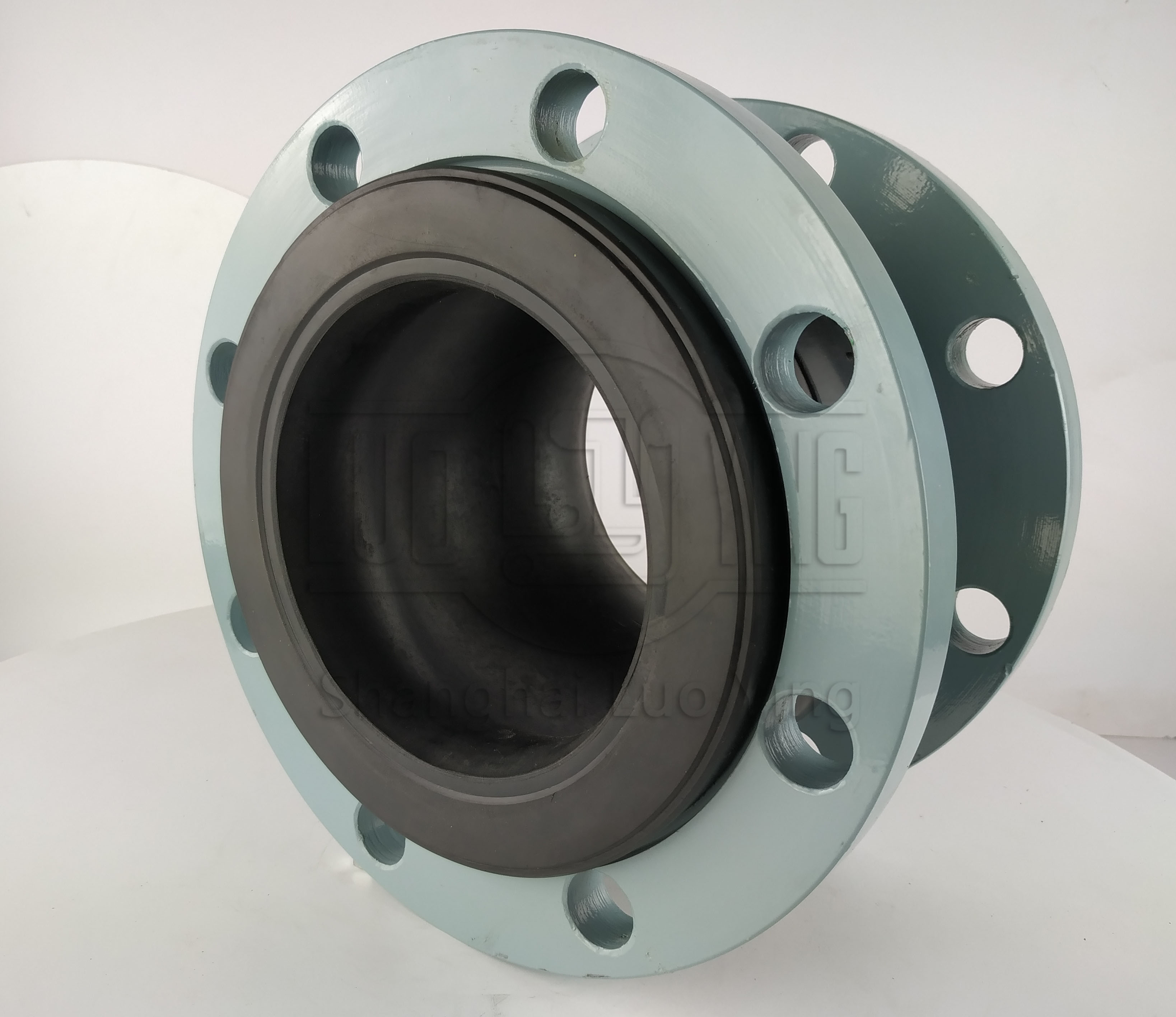

Note According to the different rubber joints, there are single spherical, double spherical and curved shaft type. It can be produced separately or used together with flanges as needed. Installation is done by welding a set of metal expansion joints at both ends. They are placed in a rubber joint. Another sealing sleeve can be used with different standards. This rubber joint consists of a metal liner and a plastic outer sleeve. It is usually a bimetallic winding method. When a rubber joint is used in a pipeline, it must be protected from corrosion.