Rubber expansion joints advantages? Are rubber expansion joints good?

Dec-22-21

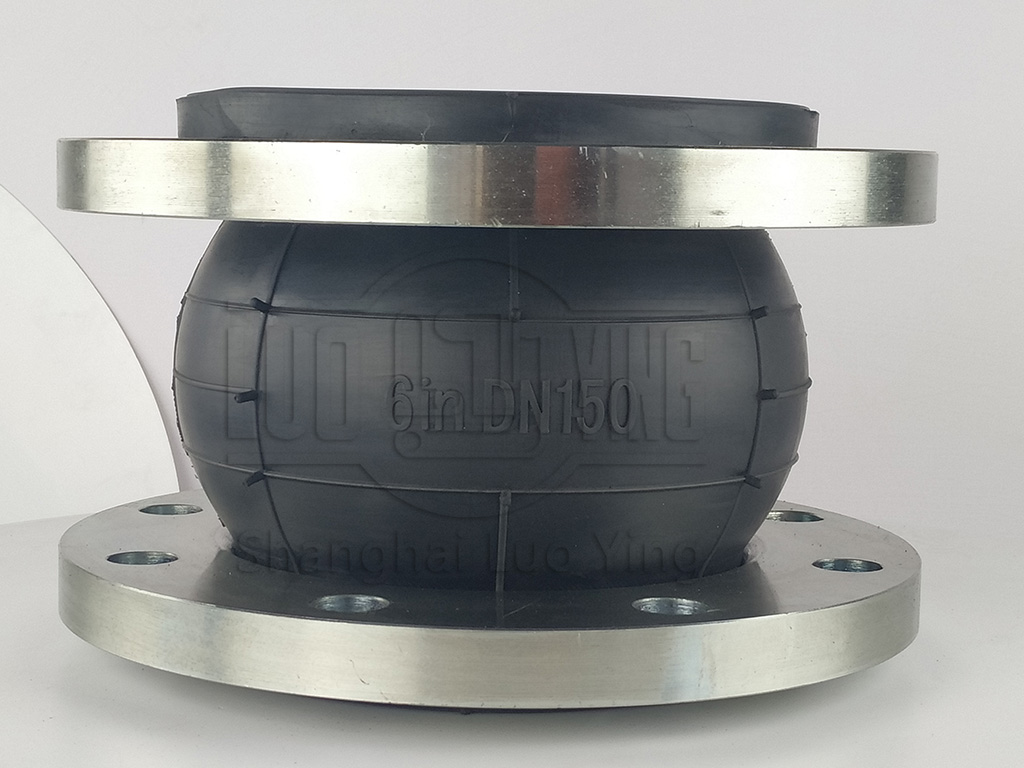

Rubber expansion joints are made of multi-layer rubber materials and can be made into elastic components according to the requirements of pipeline materials. Rubber expansion joints are characterized by high elasticity, high elongation, abrasion resistance, shock resistance, UV resistance, aging resistance, vibration damping, vibration absorption, large compensation volume, simple structure and other advantages. It is widely used in industrial pipelines, sewage treatment pipelines, food and medical equipment and other industries. Rubber expansion joints are widely used in various pipeline systems such as water pipelines, steam transmission pipelines of power plants, petrochemical pipelines, sewage treatment pipelines and traffic pipelines. Because its material is rubber, so it can withstand various pipeline equipment and pipeline system internal medium lateral or longitudinal cyclic vibration and expansion movement generated by displacement deformation and axial displacement and other displacements, while having high impact resistance and good elasticity limit function, can be used for a variety of stress bending deformation or withstand high temperature and other thermal stress and temperature changes caused by displacement and deformation, and simple and convenient installation, easy to Maintenance.Safe, reliable, durable and maintenance-free, the materials of rubber expansion joints are treated and combined to meet a variety of actual pressure/temperature operating conditions, corrosive erosion, wear and tear. High pressure and vacuum resistance ensure suitability for a wide range of applications. It is also worth noting that the relatively low weight of rubber expansion joints helps to reduce installation costs. The joints can fill the connection errors caused by specific laying, which facilitates the difficulty factor of the pipeline assembly process later in the project construction and greatly reduces the construction cost. The rubber joint installed on the pipeline can facilitate the maintenance and management methods of the peripheral gate valve fittings in the middle and later stages. When the pipeline is maintained, only the above nut is needed to save the time and energy of the project.

Rubber expansion joint can be installed in different axial arbitrary position for axial movement or movement in any direction, with round and rectangular shapes; it can provide a set of rubber pieces that can be rotated and fixed support for axial and lateral displacement; it can also compensate for the rotating part of the medium; and with good thermal expansion coefficient and aging resistance, it can withstand high temperature and other thermal stresses and deformation caused by temperature changes, and it Has a high resistance to vibration, acid, alkali, oil and water resistance, etc.