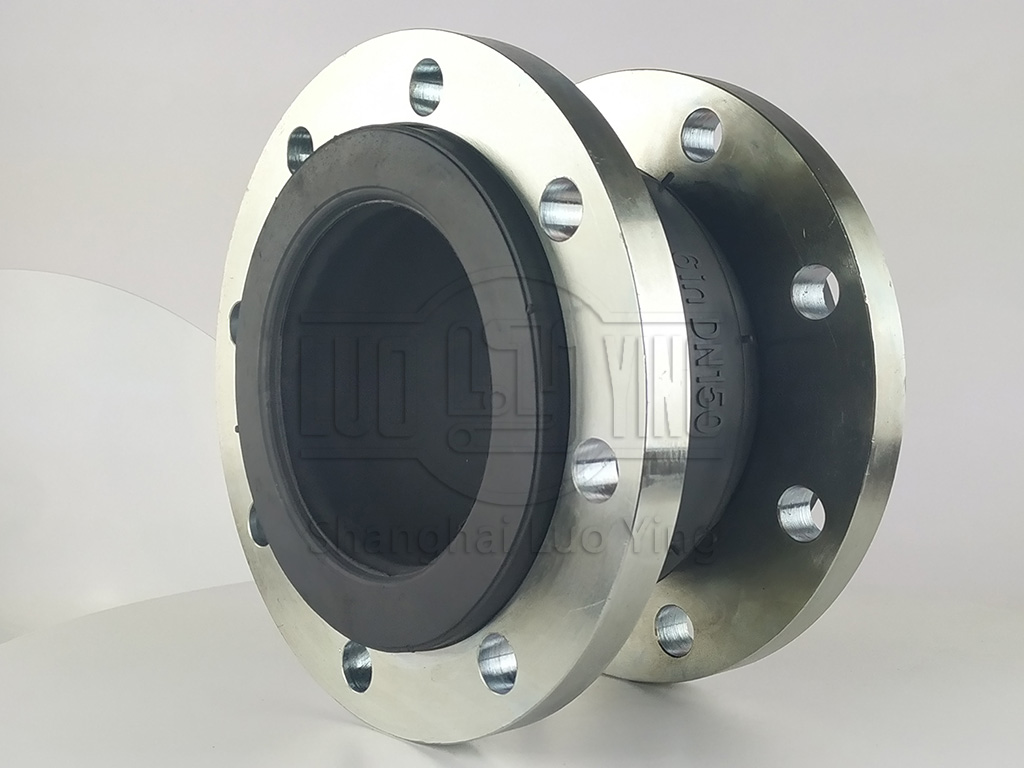

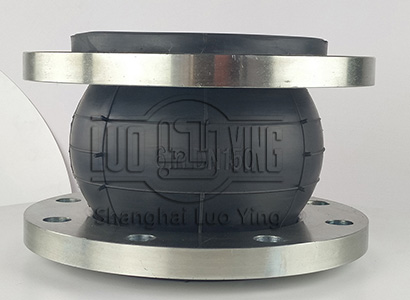

Stainless steel bendable rubber joints avoid moisture

Dec-22-21

During installation, ensure that the bendable rubber joint has no air leakage or deformation, try to keep the parts in good contact during use, and pay attention to regular inspection of the parts inside the bendable rubber joint for damage or corrosion. Flexible rubber joints use, the chemical composition of stainless steel will affect the performance of flexural rubber joints. Flexible rubber joints also have different specifications, so you need to determine the material of flexural rubber joints according to the site conditions. When the stainless steel material is hard, the wire rope clamp should be used for fixing, while when the stainless steel material is soft, the soft connection screw should be used for fixing. In order to make the bendable rubber joint work properly, the flange of the bendable rubber joint can also be screwed onto the bolt. The bendable rubber joint is a device installed on the pipeline to fix the pipeline, which plays the effect of vibration damping and noise reduction while connecting two pipes. Therefore, the role of this product is very wide.Before installation, the installation position of the bendable rubber joint should be judged according to the specific situation at the site whether there is a fixed connection with pipeline fixtures and so on. If not, pre-treatment should be carried out to make the inner wall of the installation hole smooth, check whether the threaded joint is on the same axis and tighten it with a rubber nut. Note that the flexural rubber joint should not be placed on the measured axis when the axis is measured. Otherwise, the joint will be regarded as offset. After adjustment, check that the threads are good, and then clean the mounting holes. Make sure the connection is on the same axis and the installation position has no fixed connection with pipe fixtures, etc.

Flexible rubber joints should not be placed improperly and subjected to moisture for a long time. In the environment with air, moisture or temperature change, the bendable rubber joint should avoid being placed in the sunlight or poorly ventilated place, because the surface of rubber products will have corroded surface and the performance of bendable rubber joint will be changed, which will lead to the performance of bendable rubber joint declining. Therefore, bendable rubber joints should be avoided to be placed under the sunlight for a long time. Especially the two ends of the bendable rubber joints should avoid being affected by solar radiation. If both ends of the bendable rubber joint are exposed to direct sunlight, the bendable rubber joint should be exposed to the sun at noon. Therefore, the place where bendable rubber joints are placed for a long time must be well ventilated to avoid moisture.