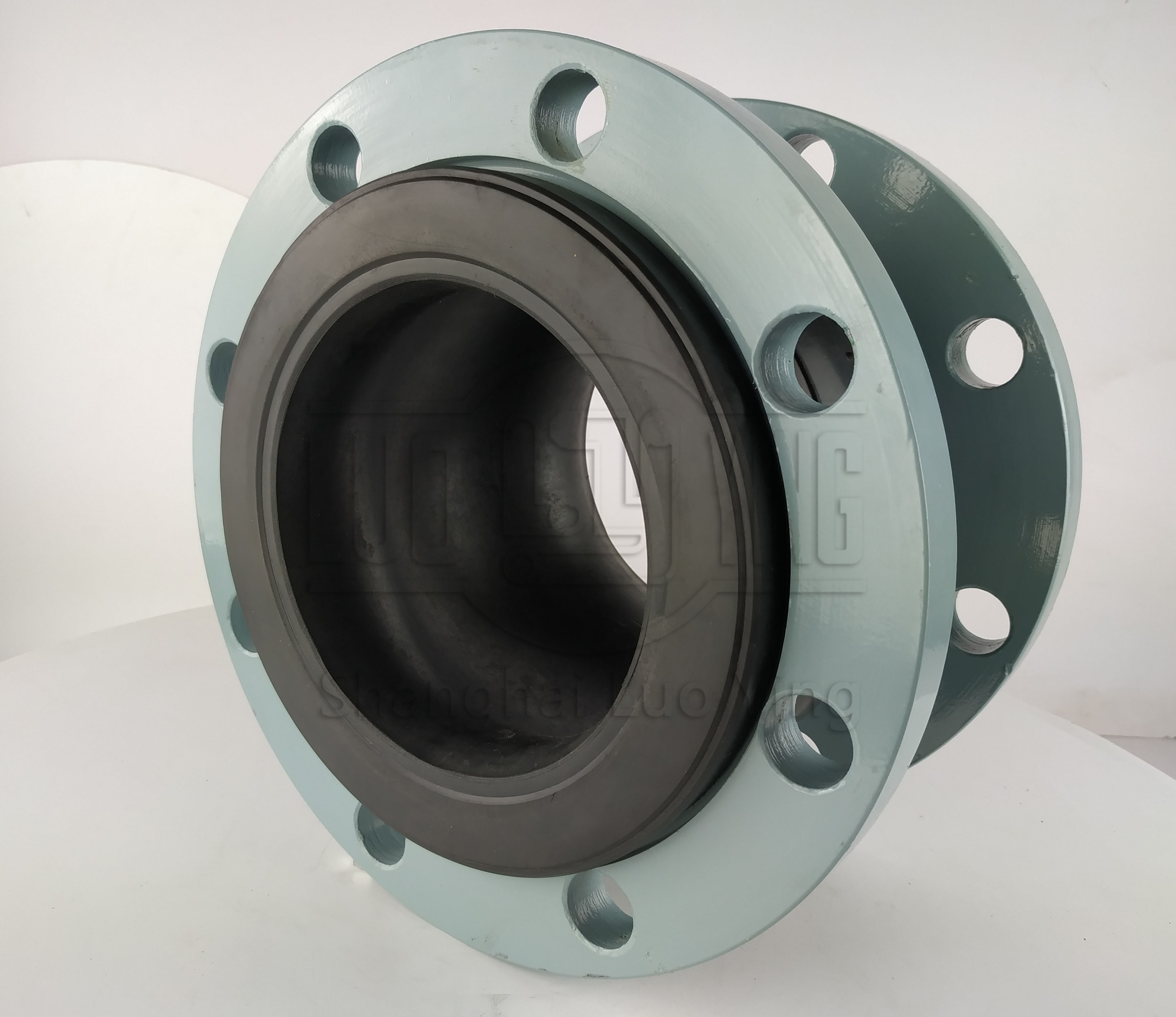

PTFE lined rubber flexible joints are resistant to strong acid and corrosion

Dec-22-23

PTFE lined rubber flexible joints can also be called teflon flexible joints, rubber flexible joints, rubber flexible joints, rubber flexible joints, pipe shock absorbers, rubber pipe joints, etc. PTFE flexible joints are based on the processing technology of ordinary rubber flexible joints, and the processing technology of fluorine lining inside the sphere, PTFE lined rubber flexible joints are mainly used in strong corrosive conditions, or in high temperature, abrasion and oil resistant environments. It is mainly used in strong corrosive conditions or in high temperature, abrasion and oil resistant environment.Applicable range and installation conditions are acid and corrosion resistant: can work at room temperature and low temperature. It can be applied to various media. Its surface will not be subject to any mechanical shock, so it will not damage the equipment. No sparks and other sparks will be generated. Will not pollute the surrounding environment, especially suitable for pipelines. High temperature and high pressure: will not be subject to any mechanical, high temperature and high pressure has a strong corrosive effect on the metal. And not affected by high temperature and high pressure can effectively avoid the oxidation caused by temperature.

Surface treatment stainless steel lined with teflon rubber flexible connection using a unique surface treatment process, so that the surface is better protected. Compared with the plastic surface, stainless steel lined with PTFE rubber hose has good oil resistance, solvent resistance, chemical resistance, wear resistance, surface tension, anti-static properties. So the rubber hose made of this material can meet the harsh environment use. Using it can reduce the loss caused by the damage of pipeline. Stainless steel lined teflon rubber hose connection product use: the product is used to connect flanges and joints; the pipe keeps its smoothness when working under pressure and works under greater pressure to avoid damage to the pipe due to external damage, which can make the equipment run more stably and reduce equipment cost.