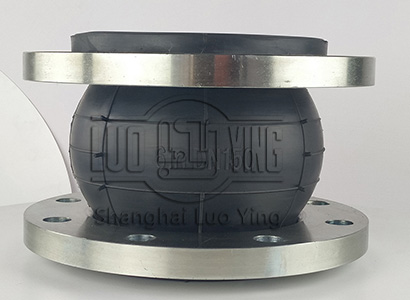

Anti-pull-off full-edge rubber joint with limit

Dec-22-24

Rubber joints have good elasticity, which can absorb the stress generated by pipeline displacement and reduce the vibration of pipeline to a certain extent. Rubber joints have good wear resistance, long service life of rubber joints, easy installation, free expansion and contraction of pipelines, good sealing performance, which can reduce noise and long service life. When installed in pipelines, rubber joints can be freely expanded and displaced to prevent pipelines from being deformed by forces. There will be no damage to the pipeline by axial force when using.Types of rubber joints: 1. Suitable for pipeline connection between different working pressures, 2. The installation of rubber valves needs to prevent damage to pipeline equipment. 3. After installation, it is necessary to check whether there is rust and corrosion in each connection part, which needs to be repaired or replaced in time. At present, it is widely used in various chemical enterprises as an anti-pull-off belt.

Rubber joints are used for the connection of pipes and components in pipeline systems, and are used to compensate for the stress caused by the displacement between pipeline expansion joints and pipes. Rubber joints are classified according to different working principles: ordinary rubber: rubber joints are mainly used for two purposes: to protect joints from damage by external forces and to reduce vibration; to prevent joints from deformation due to the action of external forces.