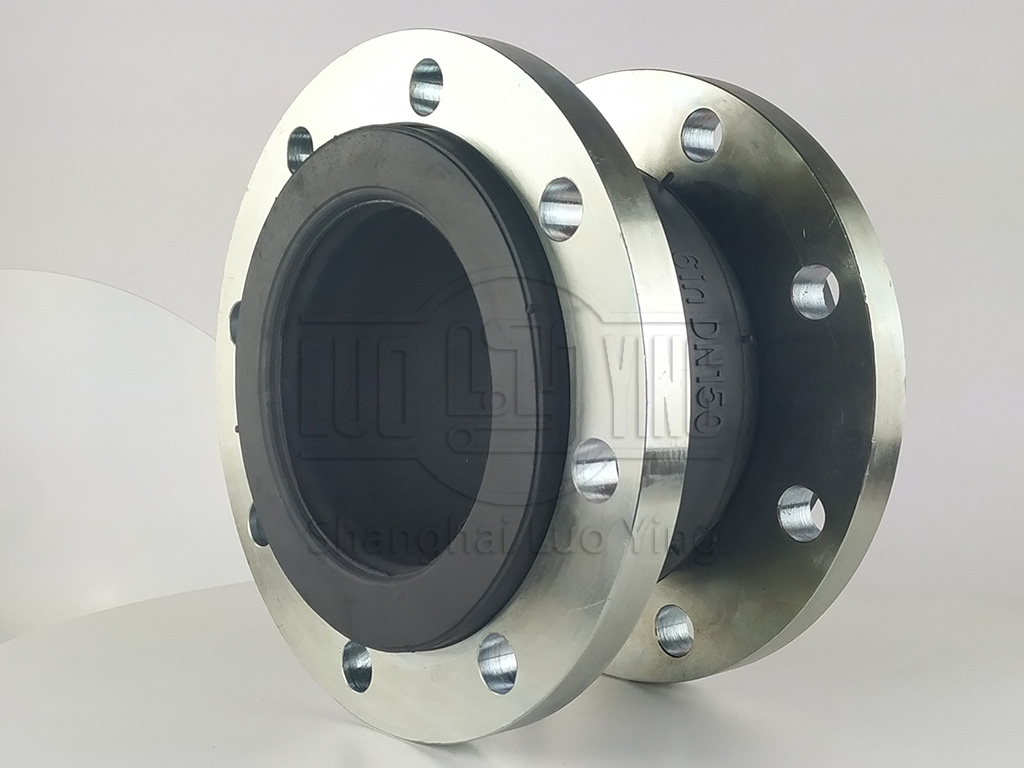

Wear-resistant and high-temperature bendable rubber flexible connection

Dec-22-24

Wear-resistant and high-temperature bendable rubber flexible connection is a kind of wear-resistant pipe with excellent performance, featuring high wear resistance, abrasion resistance and anti-aging, which is widely used in the pipeline industry. Abrasion resistance is an important index of pipe performance, and also an important factor in determining the life of the pipe. Abrasion and high temperature bendable rubber flexible connection The abrasion resistance can reach 10-20 mm thick. Its impact and wear resistance is also better, even under heavy load and high temperature, there will be no cracks and peeling phenomenon. Therefore, wear-resistant and high-temperature bendable rubber connections are widely used in coal mining, metallurgy, chemical industry, electric power, mining, building materials, shipbuilding, metallurgy and other industries are very important pipeline equipment, so wear-resistant and high-temperature bendable rubber connections are very suitable for this environment.The flexural rubber joint is suitable for high pressure pipelines, and has advantages and effects that others do not have. Generally speaking, it is made of metal material, which is more able to withstand the force. The internal construction of the sealing ring can achieve a better packing seal when working in an environment where the pipeline offset can be all right. Simple structure, easy to produce and manufacture, easy to load and unload, corrosion-resistant cloth is convenient; working pressure surface is bright and clean, suitable for PN does not exceed 2.5MPa; pipe groove, so that the gasket is easy to deformation, to avoid non-sealing gasket extrusion, the habit is more common; vessel flange can be used for 6.4MPa, pipe flange or even 25 ~ 42MPa, but with the development of pounds, the nominal diameter is reduced accordingly.

Flexible rubber soft connection The equipment is easy to align, help to avoid gasket extrusion, but the total width is relatively large, so a large bolt preload and larger flange limits. Vessel flange and pipe flange applicable PN is not greater than 6.4MPa. 3. tongue and groove clamping surface extension connection head: composed of tongue and groove surface, the gasket is placed in the groove body, not easy to squeeze the clamping surface, not easy to be material cleaning corrosion. Due to the narrow protruding surface, the required foot screw force is small, suitable for higher working pressure, sealing requirements of very serious places, such as flammable, flammable and explosive, highly or damaged substances. However, the structure is confusing, the gasket is easily squeezed in the groove, and it is impossible to remove and replace the gasket.

Flexible rubber soft connection In the transport links should be maintained to avoid knocking deformation. Steel flexural rubber soft connection consists of its own, sealing ring, screw cap, expansion tube and other core components. It can expand and contract axially in the area, and also get rid of the error caused by different axial direction of the pipeline connected from the angle, which facilitates the installation and disassembly of the gate valve pipeline. It can be expanded and contracted at will in the permitted amount of the pipe to be retracted. Once beyond its expansion volume, this will give full play to ensure the operation of the pipeline.