Reliable operation of bendable rubber flexible joints

Jan-23-27

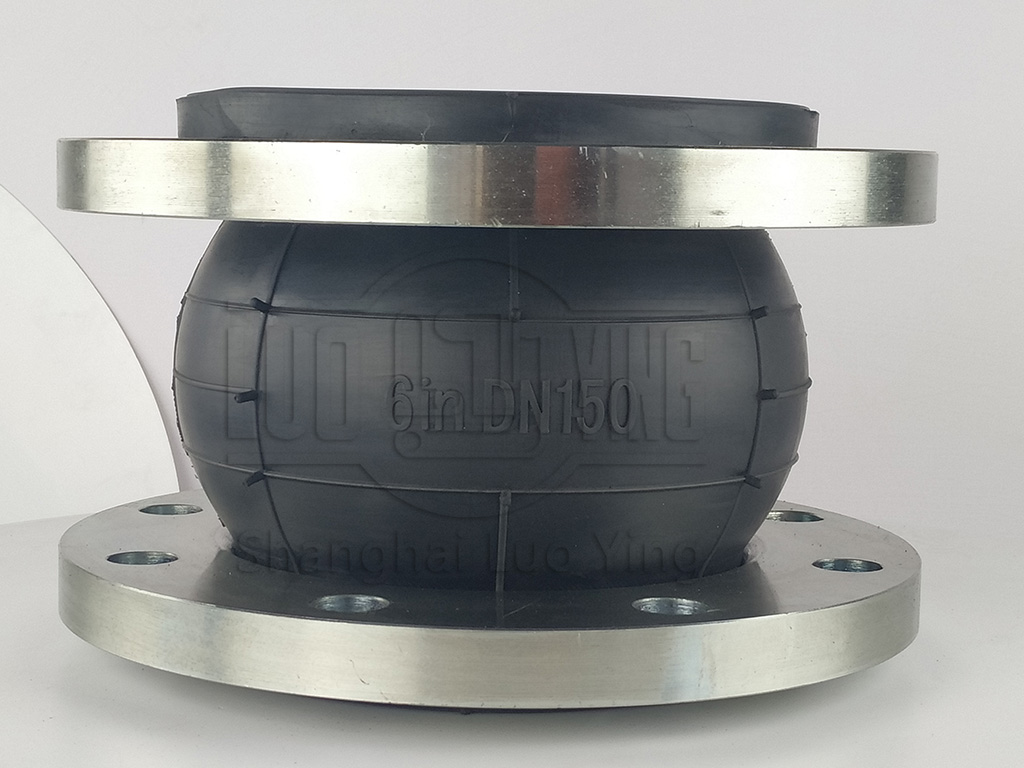

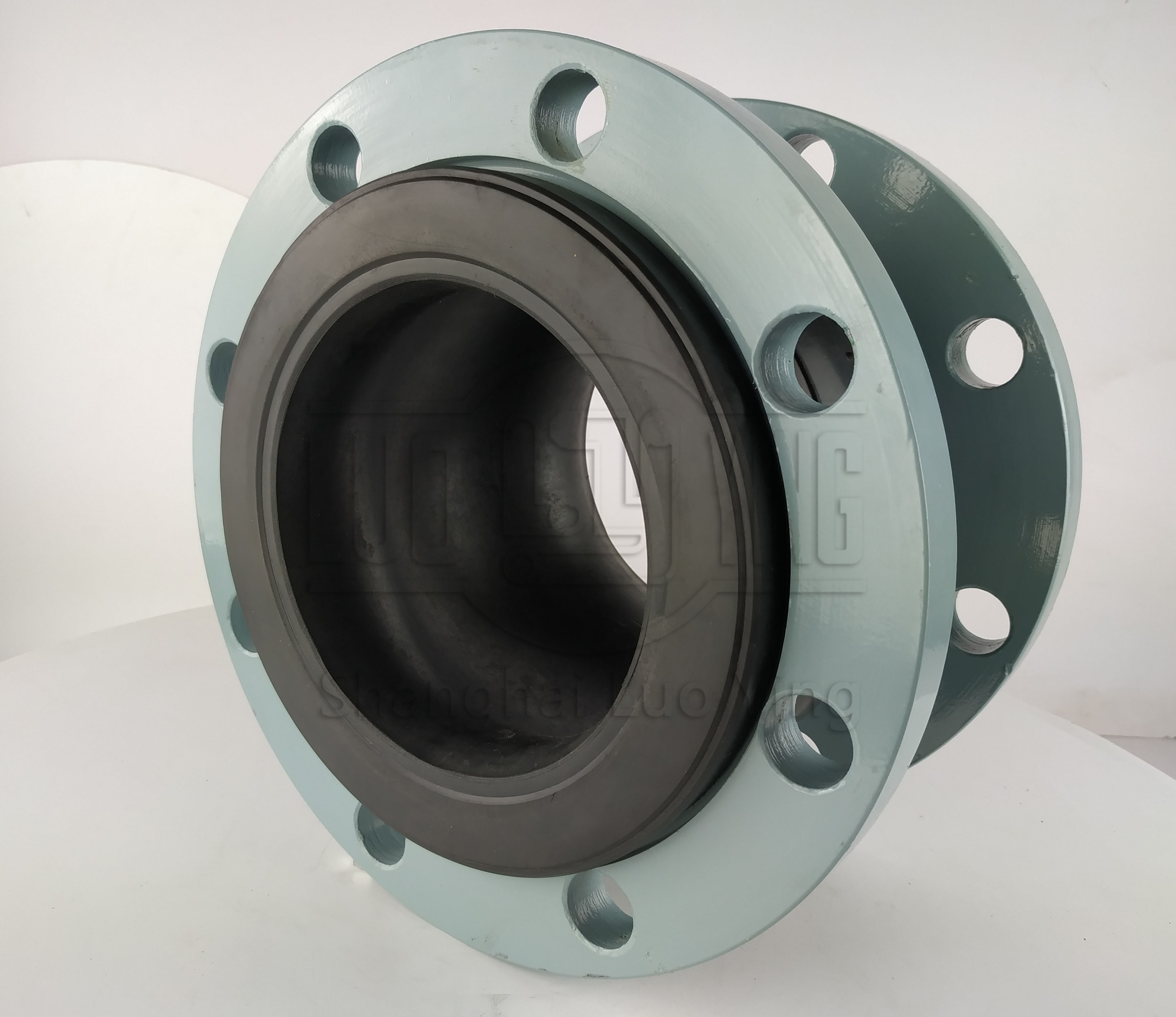

The bendable rubber flexible joint has a certain multi-directional deflection in pipeline operation and plays a vital role in compensating for the thermal expansion and cold contraction of the pipeline during operation. Therefore, it can reduce the blind driving force in pipeline operation and provide certain maintenance of the pipeline, especially the installation and maintenance of the pipeline. In the centrifugal pump entrance and exit and pipe corner, in the rolling pipeline connection without fixed immovable pier, should choose flexible flexural rubber connection and rolling pipeline connection without endless pier and positioning pier support frame, or picking and anti-pulling, and optional fixture joint, because the blind driving force when starting the pump can be transferred to the pump and pipeline in various positions according to the transmission bolt (i.e. full bolt) to prevent the driving force from being concentrated in the corner of the pipe or on the near side of the pump.Impact damage to mechanical equipment. As the product line is made of metal. With high tensile strength, high compressive strength, good soft seal performance, easy installation and other features, widely used in electric power engineering, metallurgical industry, chemical plants, water supply and drainage, wastewater treatment and other fields. The key function is the connection between centrifugal pump and pipeline. The positioning equipment is added on the basis of the original features and locked with double nuts in many places. The pipeline can be positioned at will within the allowed amount. Once the maximum is exceeded, there is positioning to ensure reliable operation of the pipeline. It is especially suitable for connections with vibrations or certain inclinations and turns.

The nut should be filled with symmetry and tightened gradually from shallow to deep. When installing the flange connector at the other end, this should be done as described above. Symmetrical nuts should be noted for range when compressing slowly. If part of the seal is found to be not tight enough during the operation, it should be tightened on part of the flexural rubber flexible connector nut to avoid leakage. If the seal on both sides is not tight enough, then the nuts on both sides should be tightened. During the whole application process, we must pay attention to the actual effect of the seal. If you find leakage and water seepage, please contact the manufacturer immediately. The manufacturer will provide you with a scientifically sound solution to prevent great damage to the safety of the pipe and the flexural rubber flexible connection coming throughout the application process.