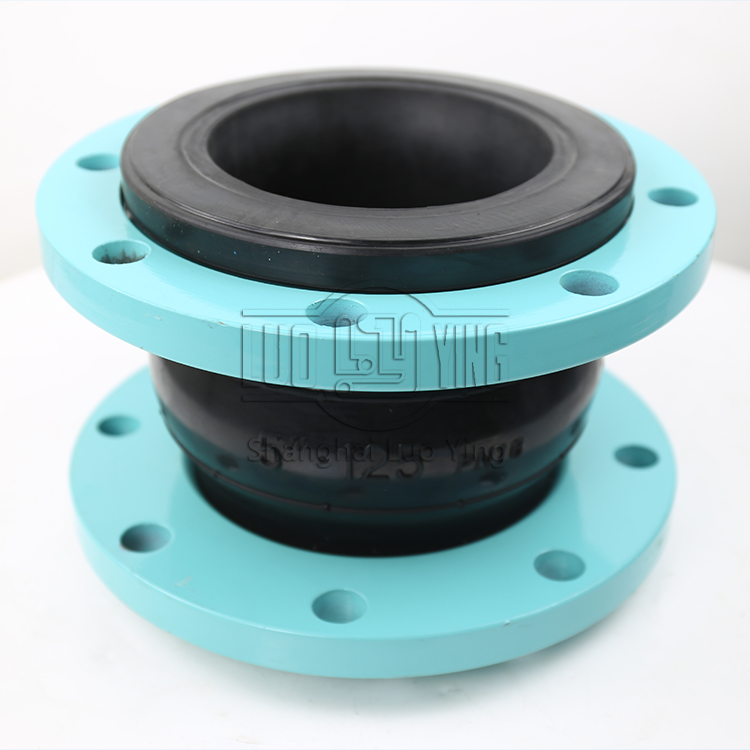

JGD rubber joint installation operation

Jan-23-31

The installation operation method of rubber joint: connect one end of the product with the pipeline on or valve fittings, and insert the pipe into the bearing mouth at the other end, and the insertion length should be slightly lower than the total length of the product. The road marking of the insertion length can be drawn on the insertion end of the pipe in advance to grasp it as accurately as possible. Rubber joint is a device to connect pipes consisting of sealing ring and fastening prefabricated components. It is mainly used to digest and absorb the offset, and cannot bear the force pushing force of the compensation connector. It can avoid the leakage or damage of the connector due to excessive offset of the pipeline.It is mainly used for pipeline connection that digests and absorbs radial offset and withstands force driving force within the allowable offset range. It is suitable for connection with pipeline electric welding. When installing, adjust both sides of the commodity and the pipeline or installation length. Top angle symmetrically tighten the valve cover foot bolt, and then adjust the positioning nut so that the pipeline can be arbitrarily expanded and contracted within the range of collection and release, locking the expansion amount to ensure the reliable operation of the pipeline.

1 . Before installation, check whether the adjusting foot bolt is in the most slack state and whether the silicone seal inside the bearing mouth will not be squeezed.

2 . When inserting the pipe, you can wipe soap solution on the pipe in advance to reduce friction and facilitate insertion.

3 . After the pipe is inserted, the adjusting foot bolt should be tightened in a continuous cycle system to facilitate the silicone seal inside the bearing mouth to be closely connected with the pipe.

4 . If the product is applied to the top of the pipe, consideration should be given to setting the top town pier to offset the driving force brought by the substance in the pipe.