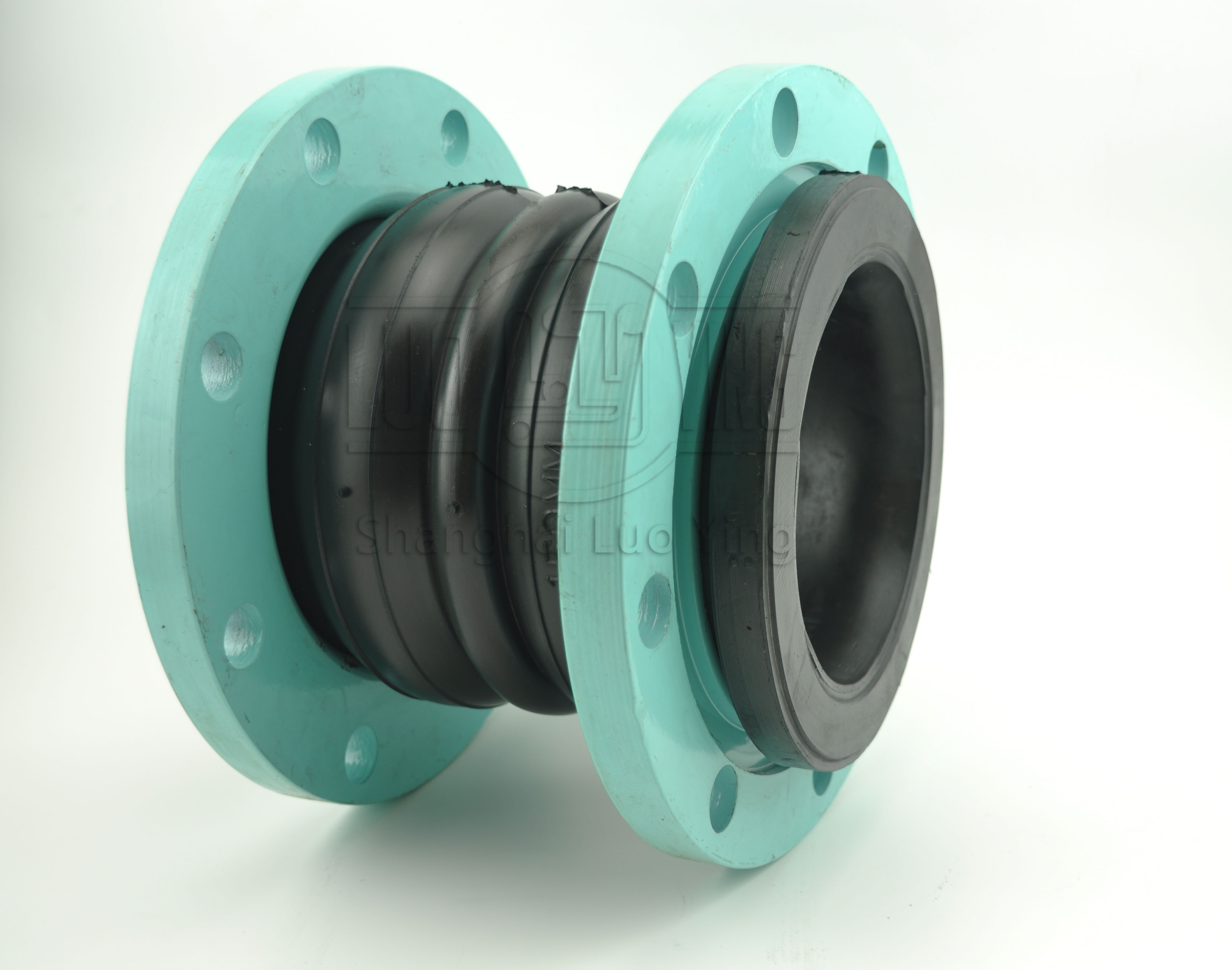

The efficacy of double sphere limit rubber joint

Feb-23-01

The special type matching of rubber joints not only saves interior space and relieves net weight, but also mainly ensures that the joint head position is not prone to leakage and has excellent airtight characteristics. Tight specifications are often reduced because of the reduced diameter of the hydraulic seal, which may reduce the cross-section of the protruding surface. Subsequently, the gasket has been replaced by a seal to ensure that the seal responds to the pairing of the protruding surfaces. In this way, in order to better press the cover closely figure only must not be large working pressure. As the required working pressure decreases, the size of the foot bolt and the total number required can be reduced accordingly. Thus, standing welding is a very high-quality commodity that relieves quality and interior space and plays a key role in the main use of industrial production.Rubber joints before and after the case of the working pressure of the left and right as much as the resulting transformation can be balanced by itself, and thus once there is a rubber joint application in the pipeline, the blind force is a must to be taken into account. Rubber joints are best to let the digestion absorb the axial offset when they are used. Or according to the adjustment of the installation part to make the radial offset of the pipe converted into axial offset, in that case.

Because of the different strain rate and thermal expansion coefficient between the material of the pipe and the material of the rubber joint, this causes not the gas pressure pushing force but the internal stress transformation of the raw material, the key causing part and the main performance is the rise of the ground stress at the raw material conversion socket, i.e. the welding. Only when the conversion of raw materials with the process of coupling will be the main performance of the force, but then the force is not the same as the force caused by the transformation of raw materials and the force caused by heat rise and cold shrinkage, and not the blind force. In the process of running operation, the general pipe size head caused by the gas pressure push force is not large and should be the size of the head working pressure will also have a certain transformation.