What is the role of rubber joints What are the benefits

Feb-23-01

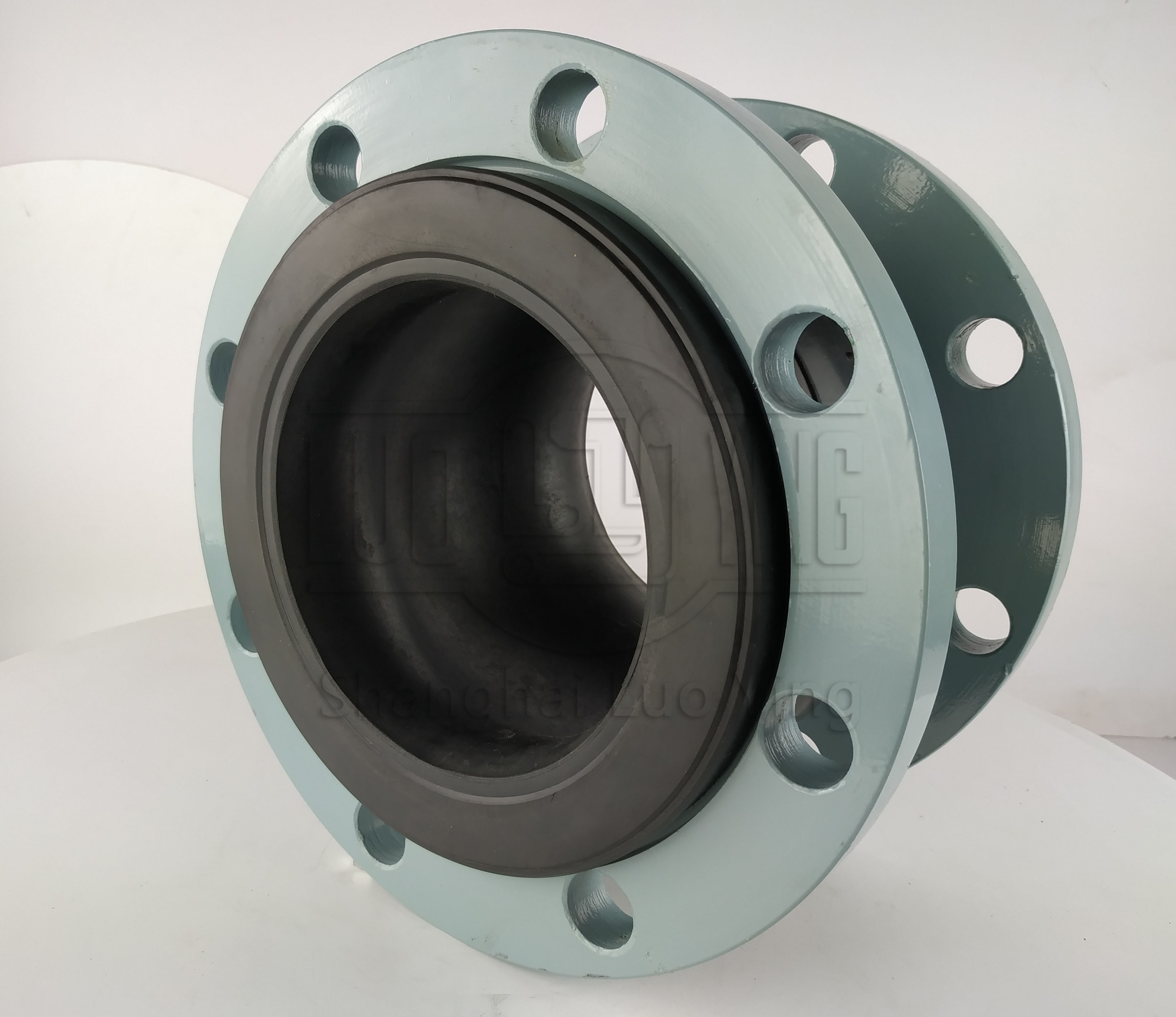

There are many different classifications of rubber joints, see which one you actually need and also see which materials, pig iron. Ductile iron. Rubber joints are crucially applied at the junction of pipeline machines and equipment, with compensatory expansion type effect, for afterwards repair or disassembly and replacement of machines and equipment convenient. If only the pipeline is connected right in the middle, that is the pipeline in use, because the pipeline is long, the pipeline will cause thermal expansion and contraction of different lengths of compensation. At present, rubber joints are mainly used in the form of reasonable expansion of the parts of rubber joints to digest and absorb the hose. The pipeline thus leads to the change of specifications. Rubber joints can be critically applied in the pipeline of mechanical equipment offset. Heating offset to get vibration. To reduce noise, it can carry out offset digestion and absorption to each direction.Rubber joints are designed on a variety of telescopic components. It is characterized by long-term application in one installation, no calibration and overhaul, offset in, not relying on rolling offset, fully automatic positioning, not limited by external natural environmental standards, and continuous pipeline operation, suitable for the application of construction water supply and drainage pipelines in various industries.

Rubber joints have certain random offset perspective. There is the role of independent expansion type compensation. Excellent seismic characteristics. Self-tightening sealing water leak-proof reliable. Can be commonly used for centrifugal pumps. Pump and pump. Pump and rubber joint, gate valve. It can be used to replace metal bellows and rubber joints in the connection of cooling circulating water pipes and other kinds of pipes. Rubber joints, etc. The operation can be trusted. Easy installation and maintenance.