What are the main structural materials of flexural rubber joints?

Feb-23-07

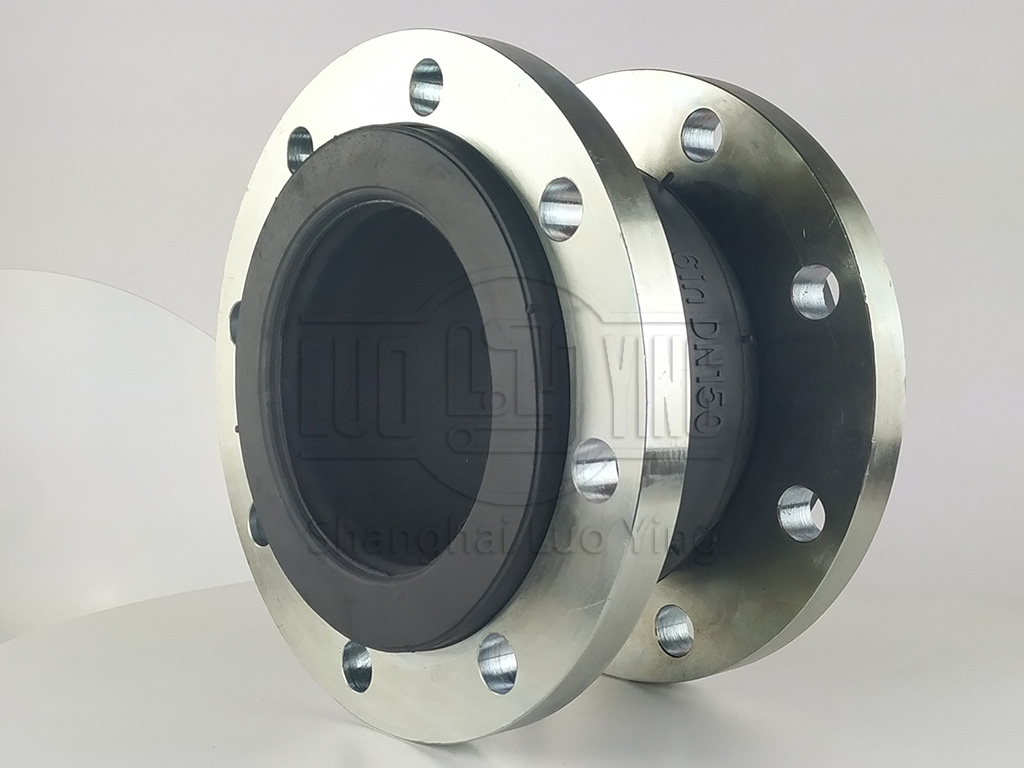

The flange flexural rubber joint is strictly over-shifted and installed during the installation process. The actual axial displacement pressure of the rubber joint is less than the support force of the pipeline, otherwise an anti-pull device should be installed to prevent the working bracket. The pipeline must have fixed support or fixed earth family, and the force of fixed bracket must be greater than the axial force. During vertical installation and overhead installation, corresponding fixed brackets and stress brackets should be installed at both ends of the product to prevent the brackets from being pulled after pressure.Installation bolts should be gradually and symmetrically tightened to prevent local leakage. The installation must be far from the heat source, and the use of media that do not meet the requirements of the product is strictly prohibited. Rubber soft connection is also known as flange bendable rubber joint, bendable rubber joint, bendable rubber joint, rubber shock absorber, etc.. The product mainly consists of inner and outer rubber layers. The tubular rubber parts are composed of cord fabric layer and steel wire ring, which are vulcanized at high temperature and pressure and then loosely combined with metal flange. It is widely used in fire-fighting, chemical, pump and valve pipeline systems to play the role of anti-vibration and noise reduction, absorbing the displacement generated during the operation of the pipeline.

Rubber soft connection is a hollow rubber product for bendable connection between metal pipes. This product can be automatically extended during use to resist the natural changes of weather. Its structural material is made of impregnated nylon cord fabric, and the inside and outside are made of high strength aging resistant rubber material. In order to prevent the product from naturally shrinking in long-term use and reduce aging and fracture, mesh steel wire is used for multi-body protection.

What are the materials of rubber shock-absorbing joints.

1 . Fluorine rubber: high temperature resistance, can be used in -30℃-+250℃ in the environment, resistant to strong oxidants. Resistant to oil. Resistant to acid and alkali. Commonly used in high temperature, high vacuum, high pressure environment, suitable for oil environment. There are many kinds of fluorine rubber with excellent performance.

2 . Silicone rubber: outstanding performance of high and low temperature resistance, in -70 ℃ - +260 ℃ in the temperature range to maintain good use of elasticity and ozone resistance. Aging resistance and other advantages, suitable for sealing gaskets in thermal machinery.

3 . NBR: It has excellent resistance to oil and aromatic solvents, but not resistant to ketones. Esters, chlorinated by the media, so oil-resistant sealing products to nitrile rubber.

4 . Neoprene: good oil resistance. Solvent resistance. Chemical media and other properties, but not aromatic oil resistance, characterized by excellent weathering and ozone aging performance.

5 . EPDM: good temperature resistance. Weather aging and ozone aging performance.