Reasons for non-smooth surface of plate-and-box type corrugated compensator

Feb-23-08

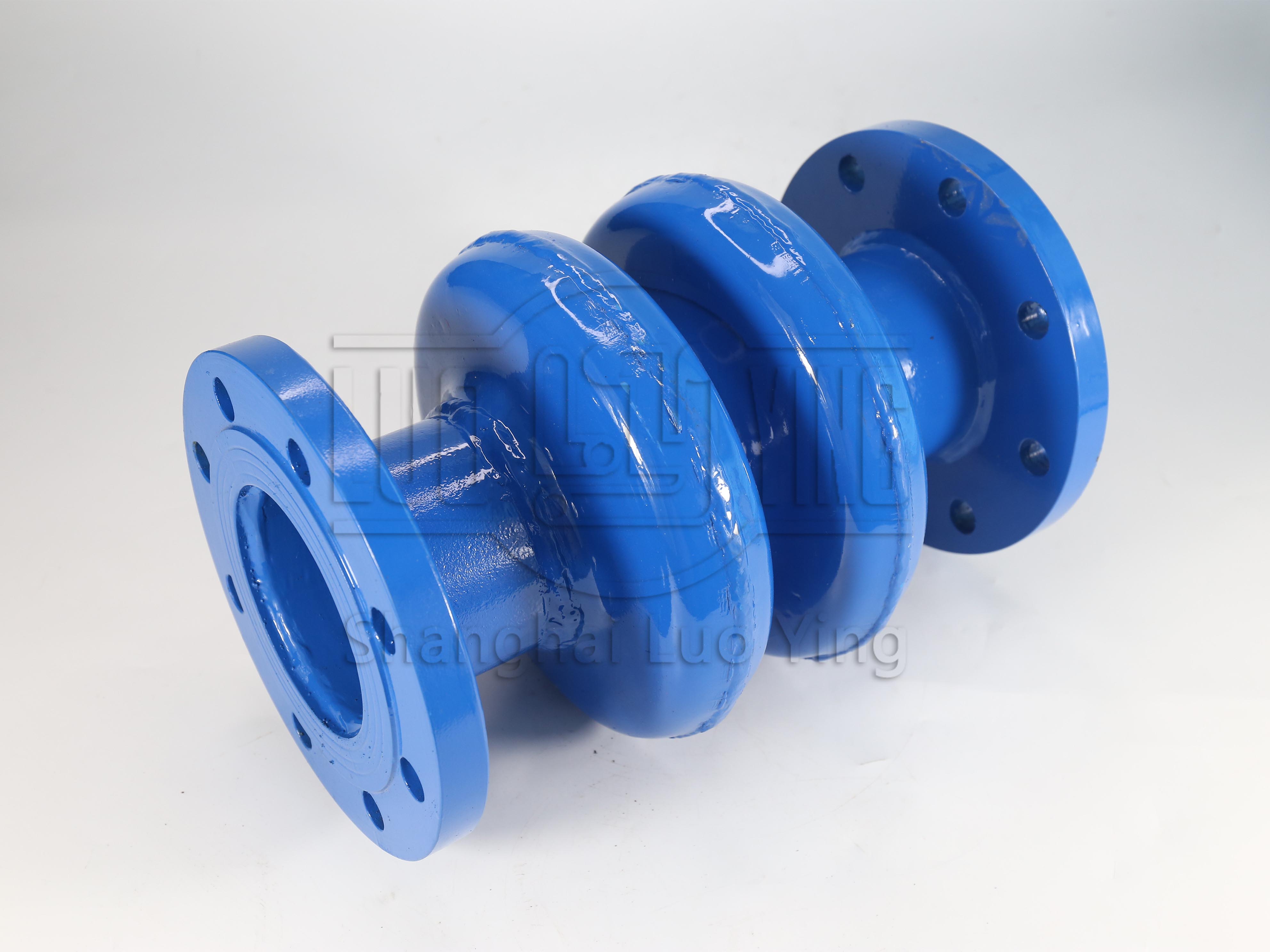

The plate-and-box corrugated compensator is planned for deep-sea, high-temperature, high-pressure use. Its higher strength means that it can have thinner walls, not only has lighter weight, but also maintains excellent corrosion resistance even at high water temperatures. The tensile strength of the plate and box type corrugated compensator is 800 to 1160MPa (116 to 168ksi) and can operate at a maximum temperature of 60°C (140°F). The tensile strength of the plate-and-box type corrugated compensator is 980-1180MPa (142-171ksi), and it can operate at a temperature of about 90°C (194°F).It has good corrosion resistance in dilute acids and is designed for environments with harsh corrosion conditions. Has a high chromium content and meet the nickel content, the addition of copper makes it has a very strong acid resistance, especially for chloride void corrosion and stress corrosion cracking has a high degree of resistance, extremely uncomplicated corrosion damage spot and cracks, pitting resistance is slightly better than other steel, has outstanding processability and weldability. Plate box type corrugated compensator in the chloride ion storage despicable environment, corrosion is very fast, and even beyond the general low carbon steel.

With the medium diameter wall thin millimeter embodiment of the welded plate box type corrugated compensator plate, with general carbon steel, inferior carbon meat steel or universal short open gold steel cold belt, cold belt welded intersection, or perhaps with warm belt welded intersection first and then by hot dial method of defeat. The plate and box type corrugated compensator combined with the general can and fat wall, generally used as structural parts, such as the transmission of static shaft, or bail flow body, fat wall used to produce furniture, lamps, etc., to ensure the weakness of the plate and box type corrugated compensator bending test. For belt feeder rollers welded plate box type corrugated compensator, generally with Q215, Q235A, B steel and 20 steel production, curved diameter 63.5-219.0mm.

On the plate box type corrugated compensator curvature, end to take the line drape, ellipsoidal squareness is not necessarily required, generally into the fire pressure war flattening test. Plate box type corrugated compensator surface appearance shall not have cracks, folding, chaps, cracks, rolling folding, leaving the layer and scarring shortcomings, these shortcomings should be eradicated to (for mechanical processing with the tube outside), eradication shall not make the wall thickness and outside diameter beyond the negative error. Where not beyond the promised negative error of other minor external flaws may not be eradicated. Scale is the length or length by width is not less than a certain scale, or length, length by width from how much to how much the scale of delivery. The production unit can produce and supply according to the requirements of this scale.