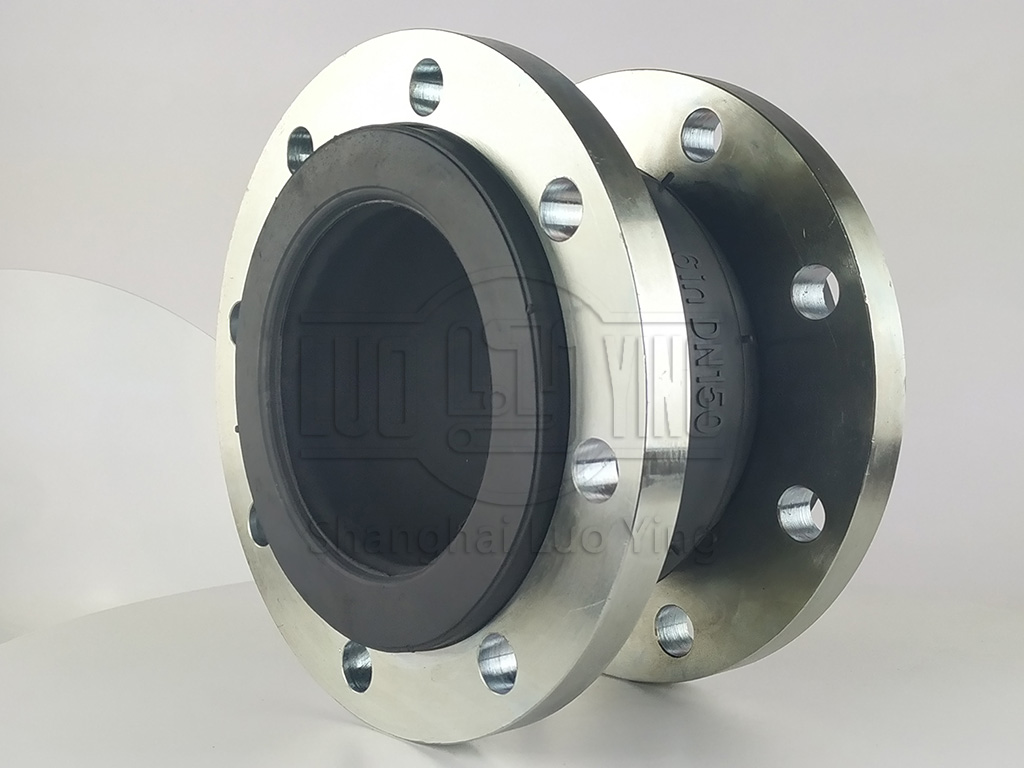

Buckle slot EPDM EPDM rubber flexible connection production process

Feb-23-08

Generally speaking, the grooved EPDM EPDM rubber joint will try to reduce this error as much as possible, but in practice, it is very difficult to reach an error of 0.2mm. In both cases, the strip is cut and sorted, rolled up, and then sent to the welding point. In addition, a coolant is used to cool the induction coil used in the heating process. Some of the coolant is used in the kneading process. A large force is applied to the kneading pulley to prevent porosity in the weld area.However, the higher kneading force applied will lead to an increase in burrs (and perhaps weld beads). Therefore, specially planned tools are used to remove burrs from the inside and outside of the tube. On the buckle groove EPDM EPDM rubber flexible connections subjected to fluid pressure are subjected to hydraulic pressure test to test its pressure resistance and quality, under the rules of the pressure does not occur leakage, wetting or swelling for qualified, some buckle groove EPDM EPDM rubber flexible connections also according to the specifications or the requirements of the demand side of the rolled edge test, flare test, flattening test, etc..

Buckle slotted EPDM EPDM rubber flexible connection is also known as stainless steel seamless tube, is made of ingot or solid billet through the perforation of the hair tube, and then hot-rolled, cold-rolled or cold-dialed made. The standard of seamless grooved EPDM EPDM rubber hose connection is indicated by the outer diameter * wall thickness in millimeters.