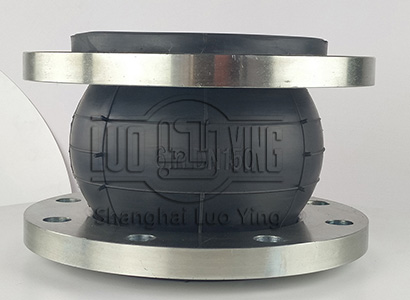

KXT nitrile rubber bendable rubber joint actual operation

Feb-23-10

KXT buna NBR bendable rubber joints made with relatively low average molecular weight have a better oleophobic appearance, which is more conducive to demoulding and better polishing. The average molecular weight of KXT nitrile rubber bendable rubber joint is relatively high, the viscosity is a little too high, and the organic residue on the exterior of KXT nitrile rubber bendable rubber joint after polishing is too much, making the exterior unpleasant and colorful.The inorganic material used in KXT nitrile rubber bendable rubber joint has an important influence on the quality of KXT nitrile rubber bendable rubber joint under the premise of ensuring the particle size and the adsorption of water in the material. It was found that the KXT nitrile rubber bendable rubber joints prepared with inorganic materials containing a certain amount of water would show serious delamination of abrasive and organic materials, and the uneven appearance of the wax body. Therefore, it is necessary to dry all the inorganic materials when preparing KXT NBR bendable rubber joint abrasives.

First of all, all kinds of abrasives and fluoride dried to constant weight are weighed according to the share and put into the mixer to mix evenly. The KXT NBR flexural rubber joint is weighed and heated until it melts. Then destroy all the wax into flakes or granules, and then weigh it with other organic materials according to the share, and then participate in the pre-heated and melted KXT NBR flexibles rubber joint, mix and melt it, so that the organic paste is mixed evenly.

KXT NBR flexible rubber joint experiment is a quick way to distinguish between general carbon steel and all types of KXT NBR flexible rubber joints. rubber joints. The concentration of the copper sulfate solution used is 5 to 10%. Before conducting the point experiment, the experimental area should be cleared of grease or various impurities, and a small area should be polished with a soft abrasive cloth, and then a drop bottle should be used to inject copper sulfate solution into the cleaned area.

Generally KXT nitrile rubber bendable rubber joint will form a layer of exterior metallic copper in a few seconds, while the exterior of KXT nitrile rubber bendable rubber joint will not occur copper precipitation or show copper color. The cut edge of the specimen should be finely ground, then cleaned and passivated in nitric acid (specific gravity 1.42) at a volume concentration of 20-30% and temperature of 60-66°C for half an hour. The volume concentration of KXT NBR flexural rubber joint is 10%, heated to 71℃ When .302 and 304 steel are immersed in this hot solution, they are corroded quickly and many bubbles occur, and the specimens turn black within a few minutes.