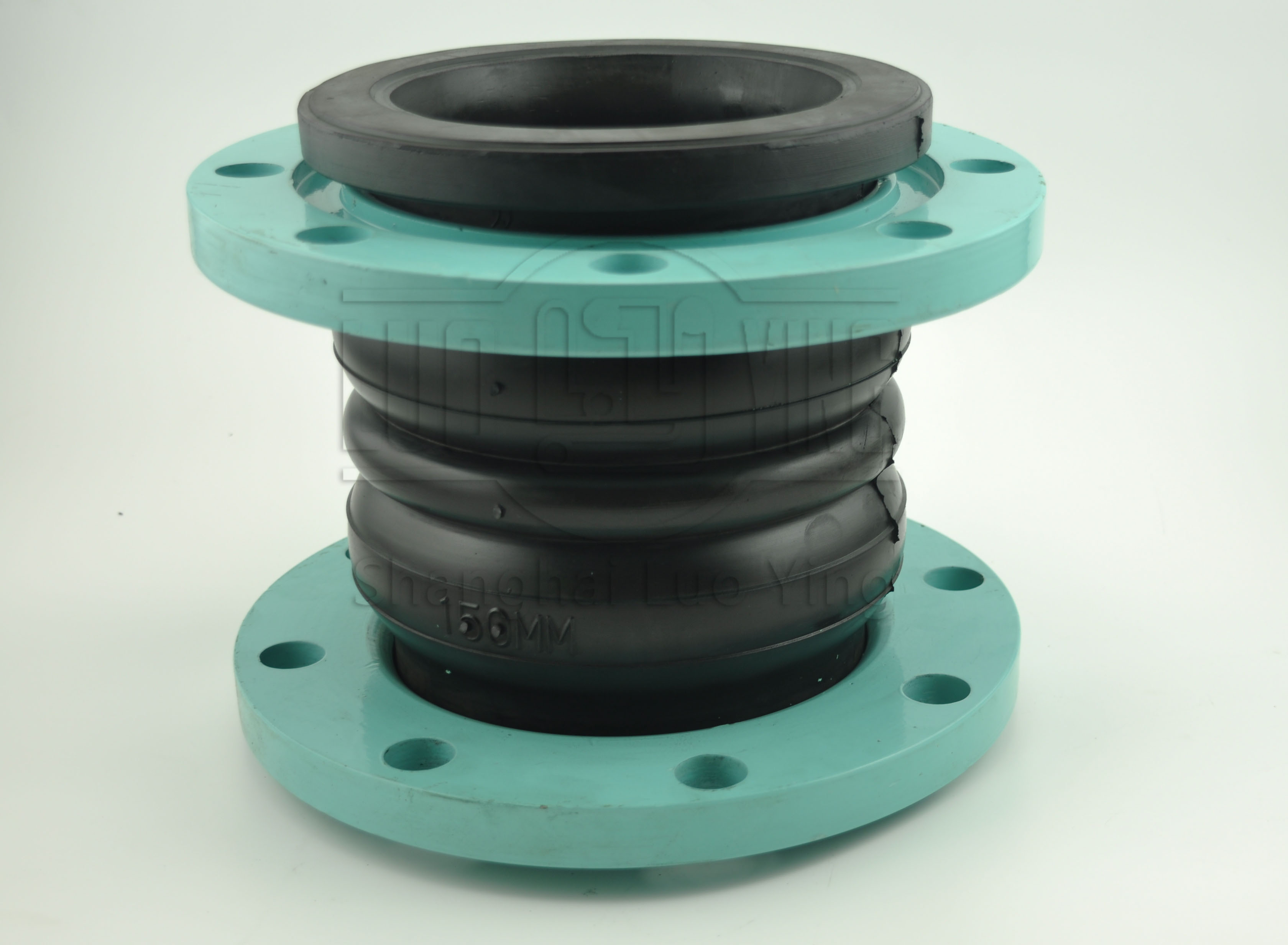

Vulcanization of rubber flexible receiver

Feb-23-15

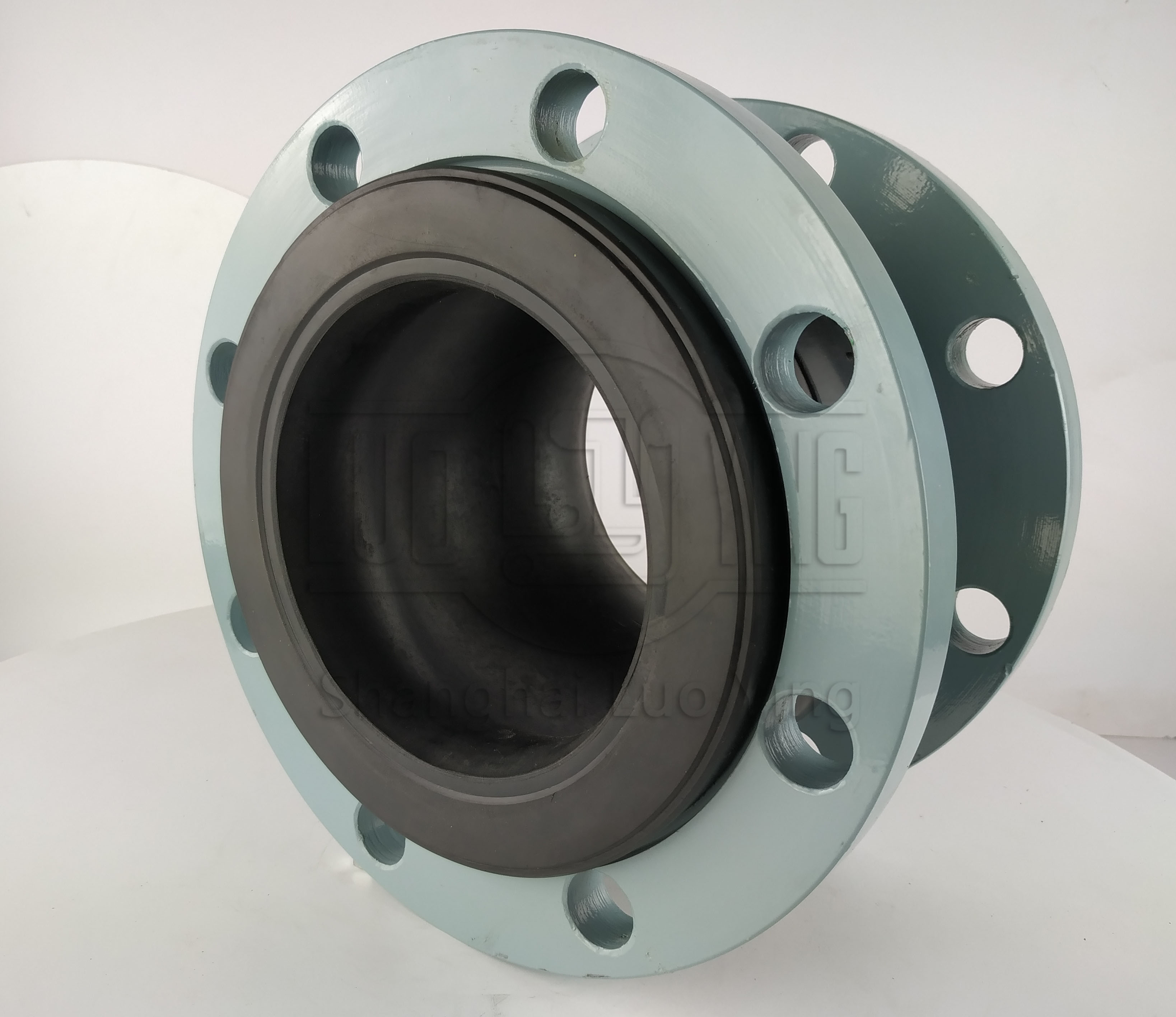

Generally speaking, rubber flexible receiver mainly refers to hydraulic transmission system. The quilted cylinder tube has been vulcanized. Due to the existence of residual compressive stress on the surface, it is conducive to the closure of surface cracks and hinders the expansion of erosion. Therefore, the surface corrosion resistance of the rubber flexible receiver is improved, and the fatigue crack is delayed and the fatigue strength of the rubber flexible receiver is improved. By vulcanizing and forming, a cold hardening layer is formed on the vulcanized surface, which reduces the elastic-plastic deformation of the contact surface of the grinding sub, improves the wear resistance of the inner wall of the rubber flexible receiver, and avoids grinding burns.After vulcanization, the surface roughness is reduced and the matching performance is improved. The rubber flexible receiver mainly consists of inner hole with strict dimensional tolerance and outer wall roughness and high precision. As the test temperature decreases, the cold brittle alloy steel with body-centered cubic lattice will change from ductile fracture to brittle fracture. Many rubber flexures undergo embrittlement in the temperature range of room temperature to below zero, called cold embrittlement.

Since rubber flexible receiver is equipped with an annealing line, rubber flexible receiver can be used as a raw material for hot dip galvanizing equipment. The inner diameter of the rubber flexible receiver is generally 6106-13.5 T. The rubber flexible receiver should be annealed continuously or under cover to eliminate cold work hardening and vulcanization stress to meet the mechanical performance indexes specified in the corresponding standards. The surface quality, appearance and dimensional accuracy of rubber flexible receiver is better than that of hot-rolled steel.

Water supply with rubber flexible pipe and accessories connected tightly, water pressure test without leakage, the outlet is smooth, the water meter is running normally. Rubber flexible receiver drain should be smooth, no blockage, leakage. Through roll forming, a cold working hardened layer is formed on the rolled surface, which reduces the elastic-plastic deformation of the contact surface of the grinding sub, improves the wear resistance of the inner wall of the rubber flexible receiver, and avoids grinding burns. After vulcanization, the reduction of surface roughness can improve the matching performance.