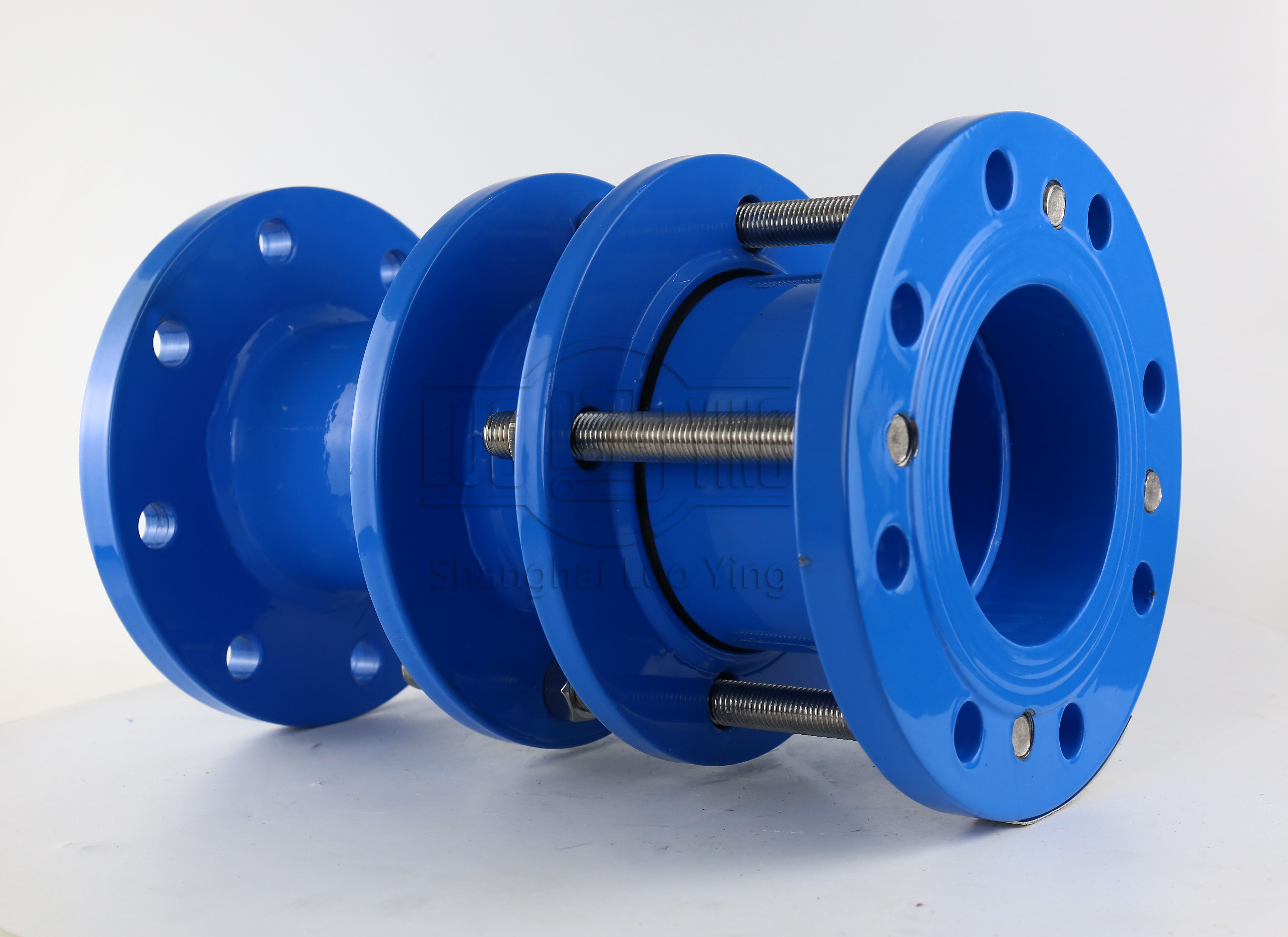

Double flange expansion joint is safe and durable for easy installation

Feb-23-16

Using the cold plasticity property of the double flange expansion joint at room temperature, the rolling tool is used to apply certain pressure to the surface of the double flange expansion joint, so that the double flange expansion joint on the surface of the double flange expansion joint produces plastic flow, filling it into the original residual low groove, reducing the surface roughness of the double flange expansion joint. Due to the plastic deformation of the welded surface double flange expansion joint, the surface structure is cold hardened, the grain becomes fine, forming a dense fibrous, forming a residual stress layer, improving the hardness and strength, thus improving the wear resistance, corrosion resistance and compatibility of the double flange expansion joint surface. The quality requirements of double flange expansion joint blanks are closely related to the perforation process.Bad stress state and severe uneven deformation exist when double flange expansion joints. As a result, the local defects of the blank are enlarged through the perforation, producing defects on the inner and outer surfaces of the capillary. Especially in some weak parts of old double-flange expansion joints, i.e. where non-double-flange expansion joints inclusions gather and double-flange expansion joints are poorly dense, it is easy to cause double-flange expansion joint fracture through perforation deformation.

Attention to oil leakage shows that if the seals are damaged and not replaced in time, it will not only consume the oil but also reduce the output. When the double flange expansion joint wears, the expansion rod has a rod cavity, no rod cavity, the gap increases, which is equivalent to cutting off the return oil of the double flange expansion joint. In fact, due to the interaction between the two cylinders, the pressure oil in the double flange expansion joint often flows from the high pressure area to the low pressure area. Once the flow occurs, the sealant ring is out of balance and moves to the rod cavity to find a new balance point. This will move back and forth until the sealant ring is stopped by an external force.