What is the relationship between the pressure of the joint in the pipe fitting, and the reaction pro

Feb-23-20

The physical quality and physical properties of nitrile rubber are gradually affected and lack practical value during the production, processing, storage and use of rubber soft joints and products due to the combined effect of internal and external factors. If maintenance personnel find softening and delamination on the surface of acid and alkali resistant rubber flexible joints in daily life, they should immediately notify the engineering department.

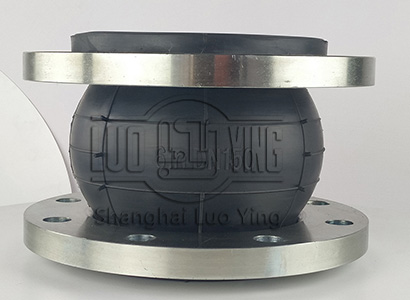

As rubber joints are used in many areas. Regardless of the perspective, the data of the connection or rubber joint in the middle of the pipe is stainless steel plate, stainless steel is very receptive. The fixed compressive strength of steel will only deform under working pressure, but it is not easy to rupture, indicating that rubber joints not only have a certain practical acceptability, but also are very obvious in terms of operational sensitivity. In the continuous operation state, the surface of the rubber molecular structure is unchained and transformed into dispersion. If not removed immediately, acid and alkali resistant rubber flexible joints will lead to physical expansion reaction under the action of pipeline working pressure (such as pipeline resonance, pipeline working pressure is too large). In the short term, large cracks will appear at low levels. Acid and alkali resistant rubber soft joints are common soft joints in pipe fittings, suitable for wastewater, industrial production, small footprint and high utilization rate. The common phenomenon is surface deformation or cracks, easy damage of rubber, or easy gap on the surface due to the increase of internal working pressure.

Due to improper installation in the assembly process can lead to excessive movement, resulting in deformation of specifications, and the pipe should be disassembled and replaced after adjustment. It consists of ball and flange. Due to the direct difference in appearance, we can clearly see that since they are composed of two parts, we can also classify them in detail according to the different connections.