Analysis of the impact on the compressive strength of rubber flexible joints in the process of polis

Feb-23-21

Under the direct influence of outdoor weather and exposure to sunlight, rubber soft joints less than the use temperature are also likely to crack. In the whole process of vulcanized rubber production, poor plastic performance or poor self-sulfur effect, corrosion of galvanized steel wire rope, etc., the compressive strength of the coherent head may be greatly affected and problems will occur in use.Too much polishing, insufficient length of steel lap, insufficient number of ladders, rubber soft joints rarely use rubber products with poor function or ineffective self-sulfur. Too much polishing of galvanized steel wire rope, corrosion of galvanized steel wire rope, etc. The compressive strength of the joint head position may be greatly affected and the joint head position may easily break in use. Some other factors that are easy to break are if the escutcheon belt does not use sealant, or the angle of the coherent head is not correct, and the position of the coherent head is also the correct guarantee measure. Lack of coherent length using fixed links and forcing beyond the coherent length, it is easy to expand the closing field also may crack. After installation, it is easy to pull here beyond the pulling and shrinking field in other areas of the pipe after installation, and it is also likely to crack.

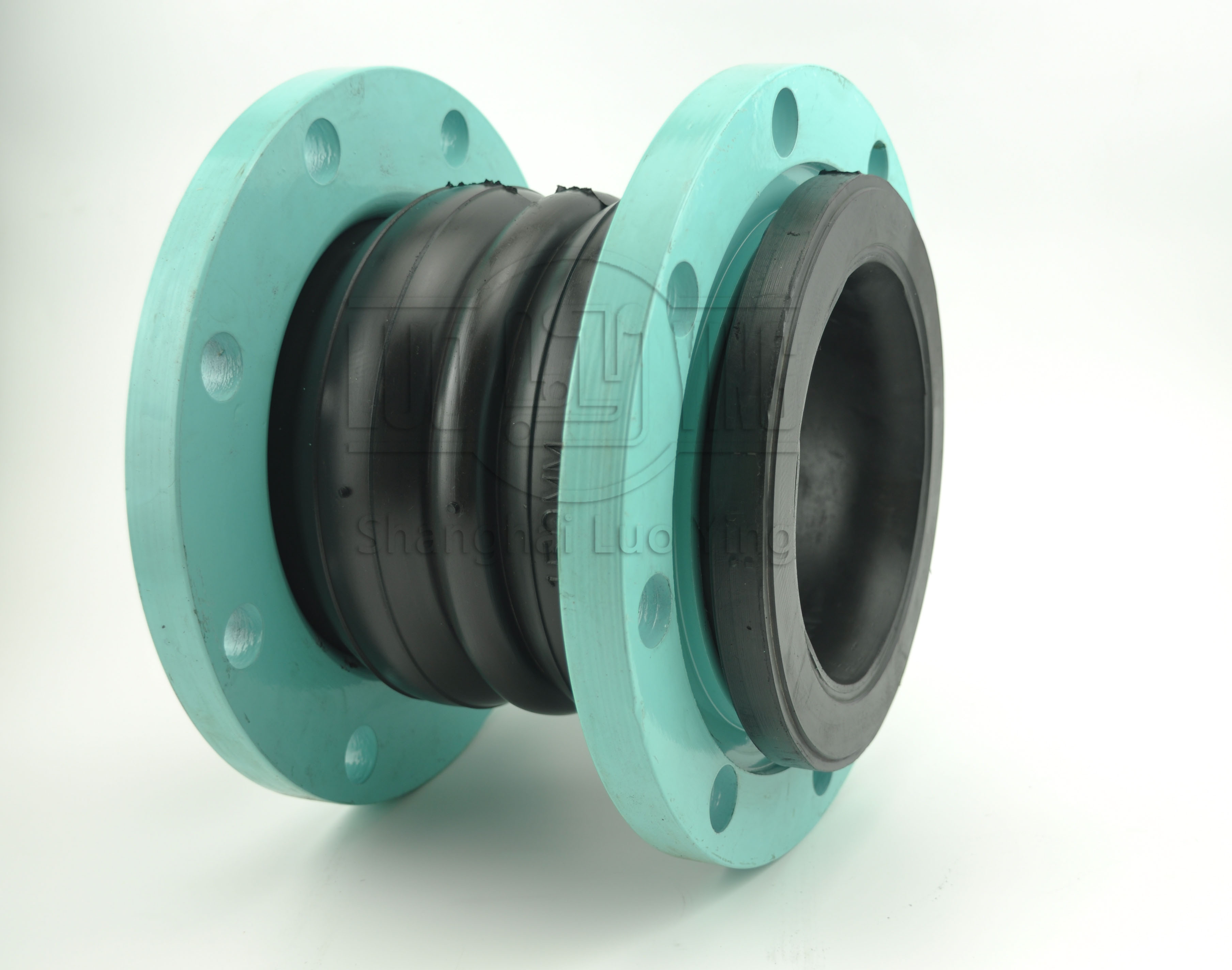

The quality of the cold glue method is very difficult. The compressive strength of the coherent head can reach 60 to 70 percent, ensuring an accurate interface method and no quality problems. Practice has proved that the use of elastic support method to reduce the harm of vibration and shock, reduce noise pollution is an effective and economic method. Elastic support in addition to metal springs, air springs, etc., common rubber fabric metal composite flexible rubber joints. Rubber flexible joint is a kind of flexible connector specially used for metal pipes.