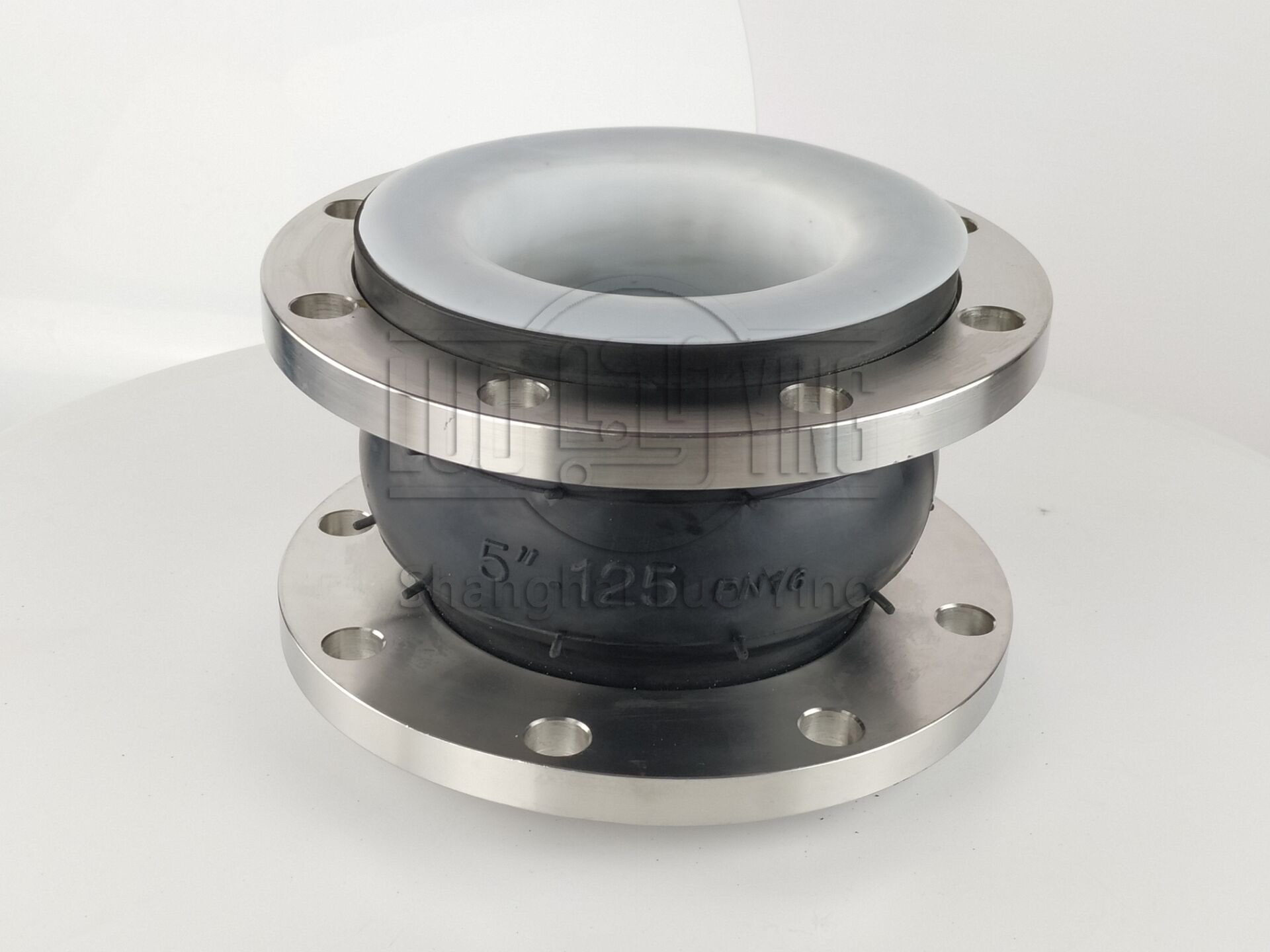

Characteristics of PTFE-lined stainless steel rubber joints

Feb-23-22

PTFE lined rubber soft joint has the characteristics of vibration damping, high temperature resistance, acid and alkali resistance, able to flex, friction resistance, etc. It is suitable for the connection of pipeline misalignment, displacement, size change and vibration parts. It can be used as feeding and discharging pipe of storage tank, tanker and other equipment, and also for other special purposes. Its scope of application is wider and its role is more complete. PTFE lined rubber joints have excellent chemical stability, corrosion resistance, is one of the better materials in the world today, except for molten metal sodium and liquid fluorine, can resist all other chemicals, boiling in water also does not change, widely used in a variety of need to resist acid and organic solvents. Sealing, high lubrication and non-stick, electrical insulation and good anti-aging resistance, excellent temperature resistance (can work under the temperature from +250℃ to -180℃ for a long time).

Advantages in PTFE-lined joints include: increased resistance to chemical interactions, non-stick wetted surfaces, increased protection against spillage, corrosion resistance PTFE lining is used as the primary surface layer for conveying fluids, while the body of the rubber or metal expansion joint is used as an auxiliary measure to prevent joint leakage. PTFE also provides additional corrosion protection for metal joints by keeping fluids away from metal coils.