General steps on the selection of rubber joints

Feb-23-22

The selection of rubber joints is an important, detailed and complicated technical work, which includes the selection of rubber joint structure, the selection of performance and the calculation of service life. Although there is no hard and fast order and rules for selecting rubber joints, the usual selection steps are the same. To select a suitable rubber joint from a large number of structures and sizes, many factors need to be considered as follows.

2 . Define the use of rubber joints in equipment or devices, and determine the working conditions of this product: applicable media, working pressure, working temperature, etc.

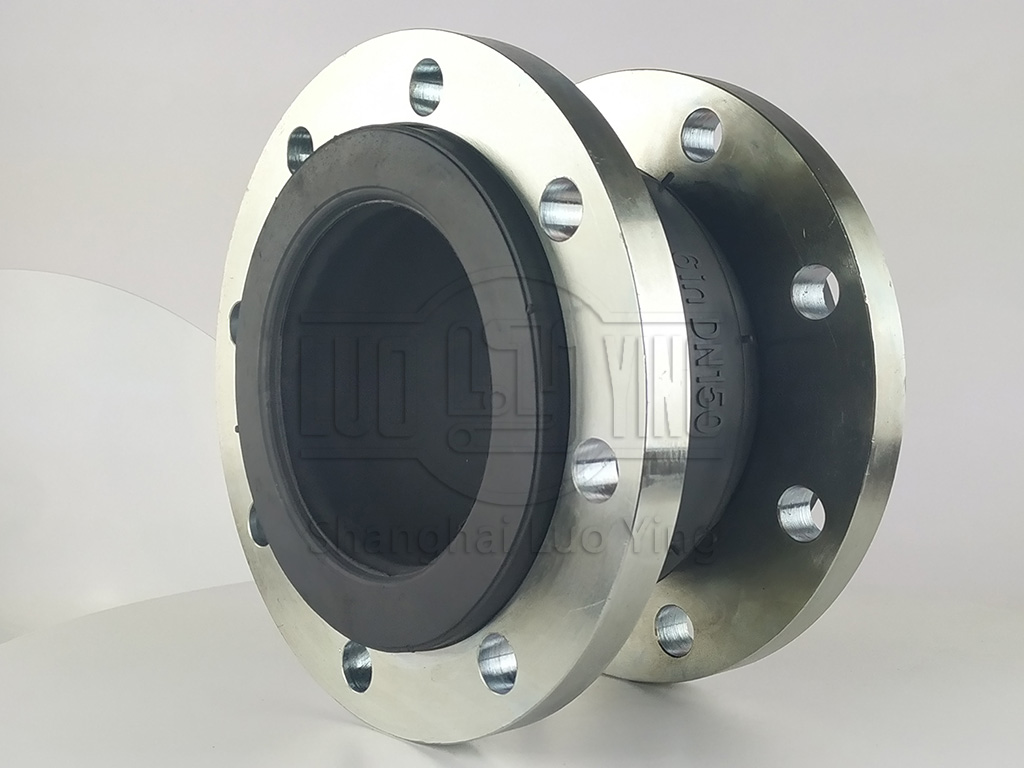

3 . Determine the nominal diameter of the pipe connected with the rubber joint and the connection method: flange, thread, welding, etc.

4 . Determine the operating side of the rubber joint: manual, electric, electromagnetic, pneumatic or hydraulic, electrical linkage or electro-hydraulic linkage, etc.

5 . According to the medium, working pressure and working temperature of the pipeline, determine the shell and internal material of the selected rubber joint: rubber, gray cast iron, cast iron, ductile iron, carbon steel, alloy steel, stainless steel, acid-resistant steel, copper alloy, etc.

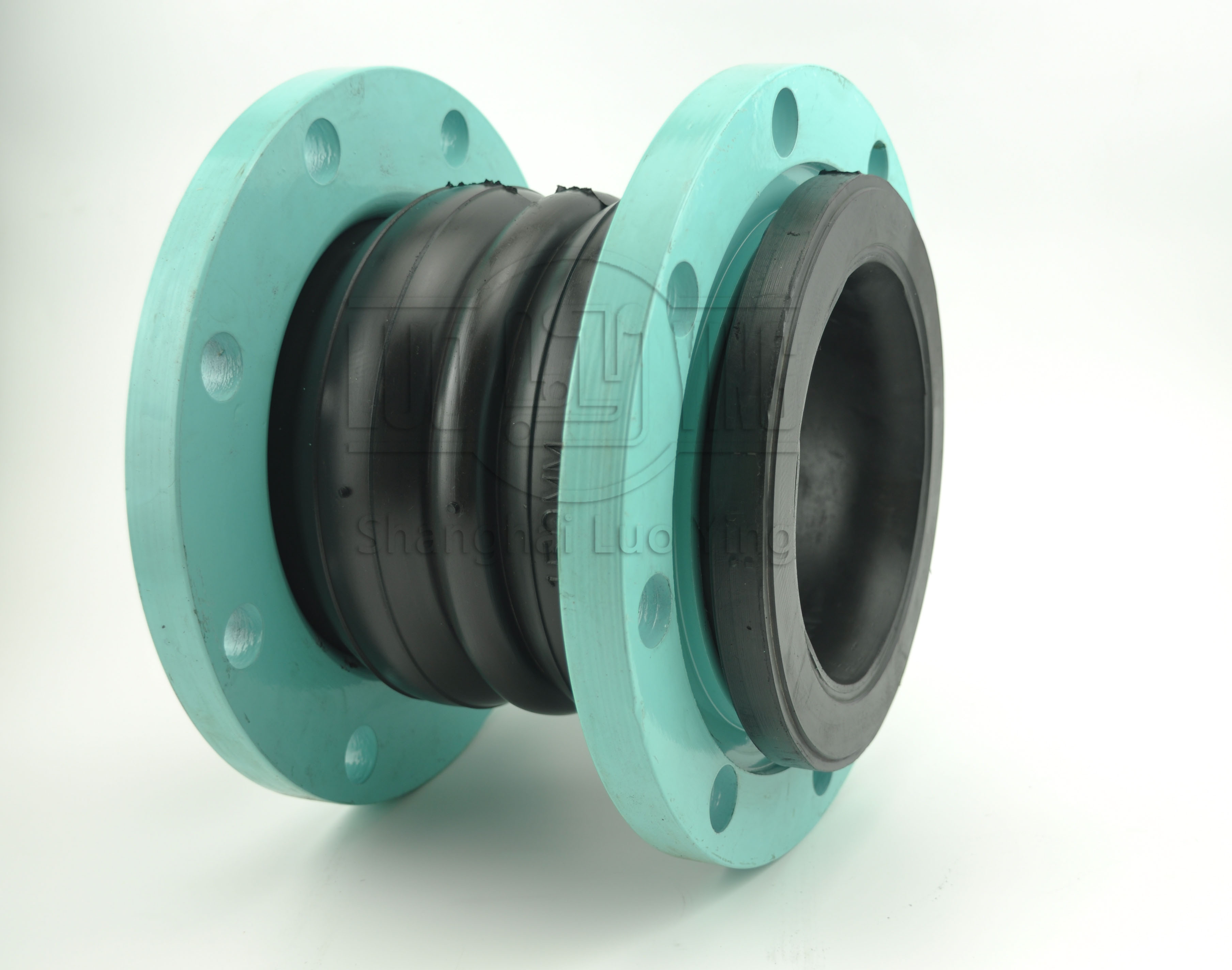

6 . Select the type of soft joint: double ball joint, single ball joint joint, reducer rubber joint, food grade rubber joint, elongated rubber joint, etc.

7 . Determine the type of rubber joints: double-ball rubber joints, single-ball rubber joints, air-blown rubber joints, threaded rubber joints, etc.

8 . Determine the parameters of rubber joints: for automatic rubber joints, first determine the allowable flow resistance, discharge capacity, back pressure, etc. According to different needs, then determine the nominal diameter of the pipe and the diameter of the valve seat hole.

9 . Determine the geometric parameters of the selected rubber joint: the length of the structure, the form and size of the flange connection, the size of the height direction of the rubber joint after switching, the size and number of the connection bolt holes, the appearance size of the whole rubber joint, etc.

10 . Use available data: rubber joint catalogs, rubber joint product samples, etc. Select the suitable product.