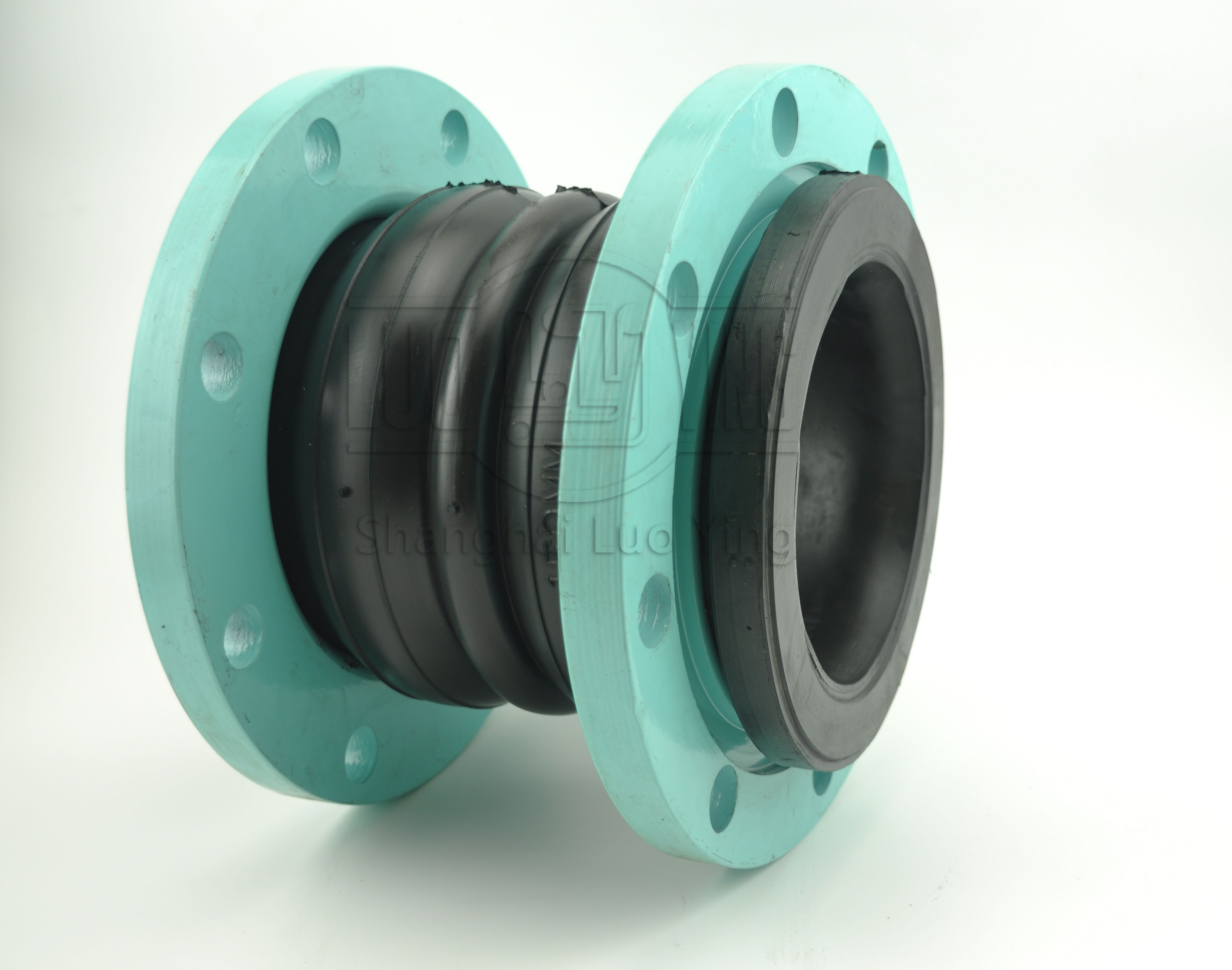

Comparison of the working performance and service life of double spherical rubber joints

Apr-23-11

Comparison of the working performance and service life of double spherical rubber jointsDouble spherical rubber joints are known as a compound of iron and carbon, with a major chromium content ranging from 10.5 - 11.5%. Formed in the 19th century, but it was not until the early 20th century that double spherical rubber joints became mass-produced and widely used. The secret of chromium content's anti-staining properties was discovered. When chromium comes in contact with the oxide called chromium trioxide surrounds the steel and provides a barrier against corrosion. Whenever the chromium trioxide layer is destroyed, and continues to create another piece of exposed chromium interacts with oxygen.

Since the connection strength is not dependent on the rigidity of the double spherical rubber joint itself, only the pressure-bearing capacity of the double spherical rubber joint itself needs to be considered when calculating the wall thickness of the double spherical rubber joint. Therefore, the wall thickness of the double spherical rubber joint can be significantly reduced (the wall thickness of the double spherical rubber joint can be reduced by about 25%). Shoulder type steps need to be welded to the ends of double sphere rubber joints and double sphere rubber joints. The cost of double sphere rubber joints will be higher than ordinary groove type connections when the same wall thickness is used.

High connection strength, because of the good rigidity of the flange connection, so its connection strength is much greater than the double sphere rubber joint groove type connection. Since the connection strength does not depend on the rigidity of the double spherical rubber joint itself, only the pressure-bearing capacity of the double spherical rubber joint itself needs to be considered when calculating the wall thickness of the double spherical rubber joint. Therefore, the wall thickness of the double spherical rubber joint can be significantly reduced (the wall thickness of the double spherical rubber joint can be reduced by about 25%).