Difference between fluoroelastomer rubber joints and nitrile rubber and silicone rubber

Apr-23-12

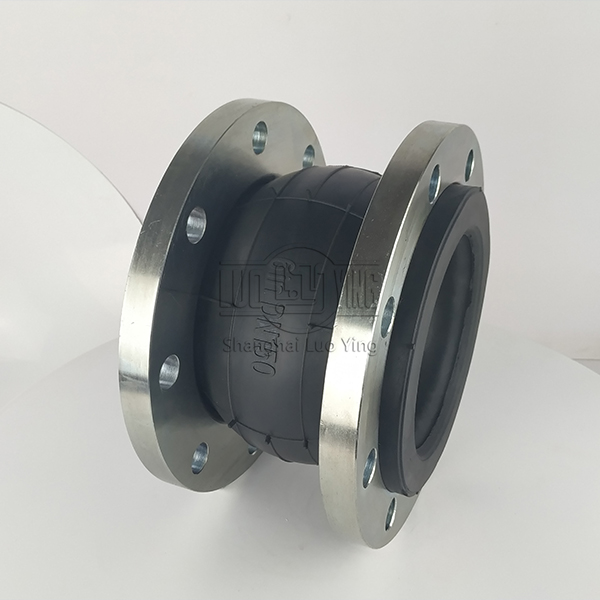

Difference between fluoroelastomer rubber joints and nitrile rubber and silicone rubberRubber joints and multi-sphere flexible rubber joints belong to the same type of flexible rubber joints, mainly due to the different number of rubber flexible connections between connecting flanges, and therefore different structures. Due to its increased length, the effect of vibration damping and compensation is better than that of single-body flexible rubber joint. However, due to the increased length, the use of many items is restricted and users should consider the installation at the pipeline design stage to avoid the inability to match the pipeline later.

NBR is usually produced by low-temperature emulsion polymerization method du, with good oil resistance, high wear resistance, good heat resistance zhi and strong adhesion. The missing dao point is poor low temperature resistance, poor ozone resistance, poor electrical properties, and slightly lower elasticity.

NBR is mainly used in the manufacture of oil-resistant rubber products. A kind of synthetic rubber made of copolymerization of butadiene and acrylonitrile. It is oil-resistant (especially alkane oil), synthetic rubber with good anti-aging properties. The content of acrylonitrile in nitrile rubber (%) has 42 ~ 46, 36 ~ 41, 31 ~ 35, 25 ~ 30, 18 ~ five types. The higher the content of acrylonitrile, the better the oil resistance, but the cold resistance is reduced accordingly.

It can be applied to air at 120℃ or oil at 150℃ for a long time. In addition, it has good water resistance, sealing property and good adhesion. It is widely used in the manufacture of various oil-resistant rubber products, various oil-resistant gaskets, gaskets, sleeves, soft packaging, soft rubber tubes, printing and dyeing rollers, cable rubber materials, etc. It has become an indispensable elastic material for vehicles, aviation, crude oil, printing and other fields.

NBR is particularly strong, and the compatibility with other polymers is generally not good, but with neoprene, modified phenolic resin, especially chlorine-containing polymers are compatible and often used. In addition, NBR is often used with natural rubber and styrene butadiene rubber in order to improve processability and serviceability. It should be emphasized that NBR has good oil resistance, which is reduced when used with other polymers (except PVC).