Excellent heat resistance of silicone rubber flexible coupling

Apr-23-12

Excellent heat resistance of silicone rubber flexible couplingApplication or storage of 304 rubber flexible joints to prevent high temperature, ozone oil and strong acid and alkali natural environment. Outdoor application or the pipeline rushing to the sun and sun wind should be set awning to prevent strong storms, drenching rain and wind turbidity. The surface layer of the interface and the raw material of the wind stall should be painted strictly. Because of the aging problem of rubber products, should be immediately tested to remove and replace. Selection of 304 hard rubber joints applied substances: for example, 304 hard rubber joints usually available substances are 0-60 ℃ general water, unique products such as: oil, acid, alkali, high temperature and other corrosion and materials.

Silicone rubber soft joint characteristics: because of the transparency of this material is good, strong tensile strength. High cost, use: silicone tube, protective shell and other advanced products must have high elasticity. Silicone raw materials can be divided into solid silicone and liquid silicone according to their physical properties. Solid silicone is mainly used for molded products. For example, silicone sleeves, silicone tableware, silicone buttons, etc. Liquid silicone is mainly used for extrusion molding products, such as silicone pacifier, silicone tube, etc. Insulated silicone mat, excellent heat resistance, silicone (food grade silicone) can withstand 200℃ high temperature for long term use. The raw materials used in the production of this product meet SGS standards and can be produced without toxicity according to FDA food grade.

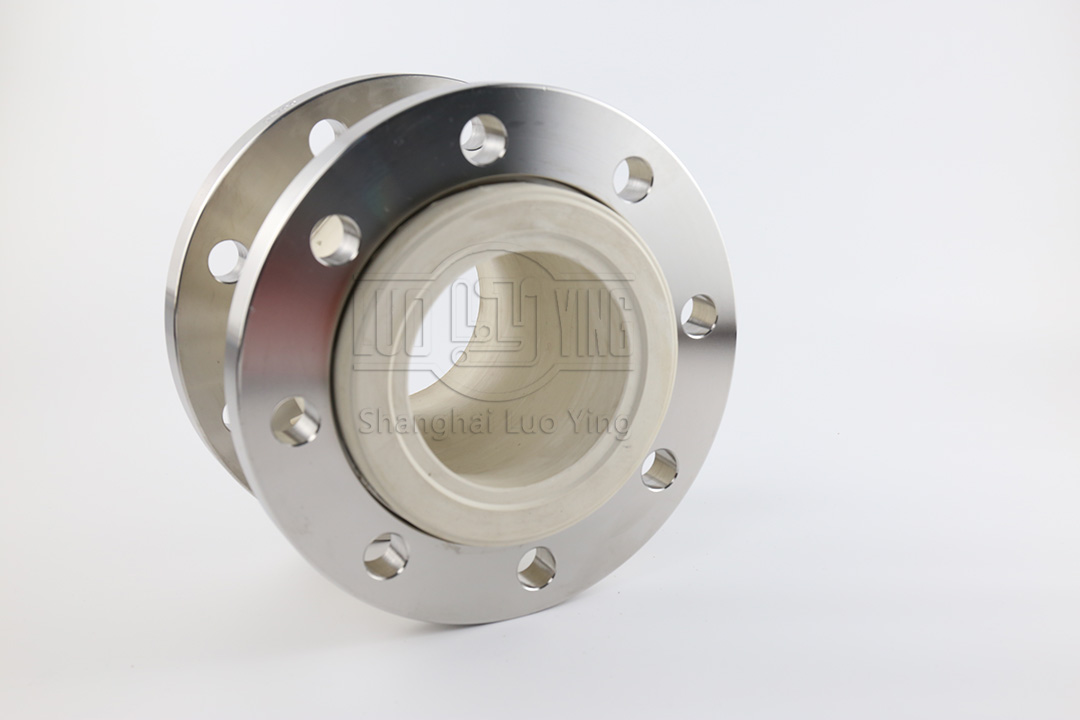

Used to connect or seal two systems or mechanisms, silicone rubber flexible joints are ring-shaped components whose planned purpose is to block or control fluid leakage in equipment. Sealing rings commonly used in various applications include continuously moving equipment such as rotary or reciprocating shafts and cylinders, which form an important part of hydraulic and pneumatic systems, including seals used in automotive windows. Silicone rubber flexible joints are seals made of natural and synthetic rubber. Silicone rubber rubber flexible joints have many different uses in industry.