What homework needs to be done in advance when using bendable rubber flexible joints on motor equipm

Apr-23-12

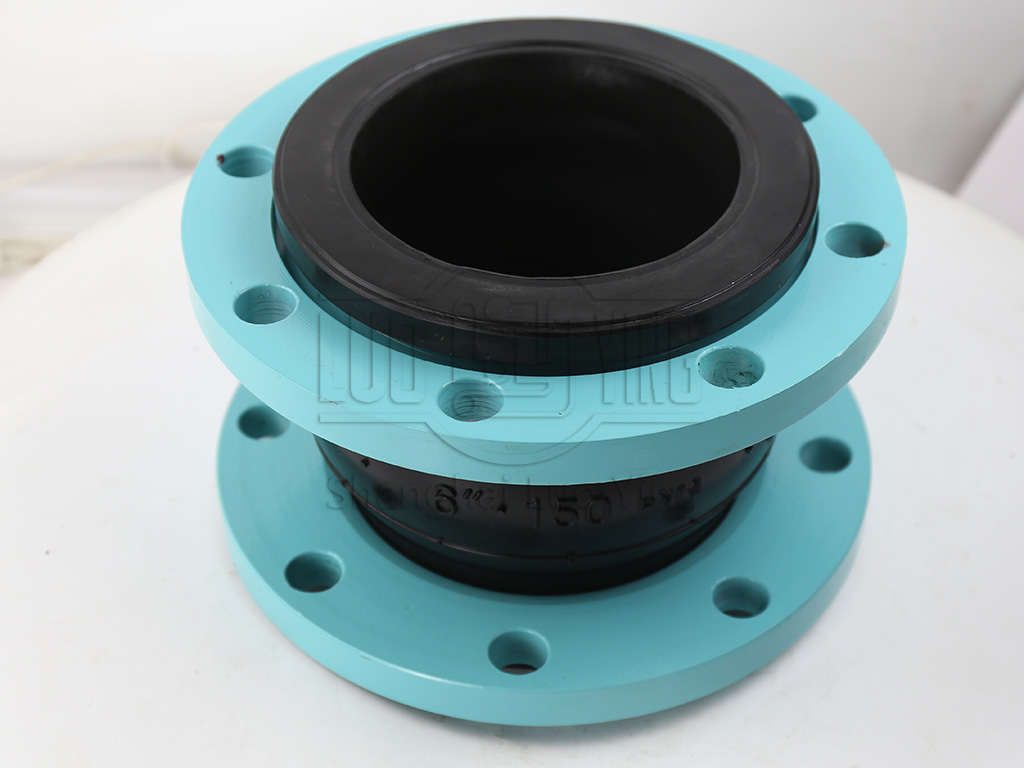

What homework needs to be done in advance when using bendable rubber flexible joints on motor equipment?If the rubber joint has pressure regulation, controller control, check, adjust the pressure of starting and disconnecting, according to the pressure regulation, the system apparatus to check the motor full load current can not exceed the large allowable current. Before running the booster rubber joint machinery and equipment, check whether the bendable rubber flexible joint is stable and firm; whether the rubber joint is full of water and whether the liquid can be freely based; whether the pipeline can be powered normally; whether the gate valve on the inlet pipe is fully opened; after the rubber joint is started for a longer time, the import and export gate valve should be opened slowly; if a pressure gauge is installed, check the working pressure; any adjustment needed for normal operation.

Metal rubber joints are made of zinc alloy die-casting, production and processing, the surface is generally hot-dip galvanized, hard chrome, unique on-site surface treatment as required, the appearance of goods is beautiful and generous, tight structure, no exit hole, high compressive strength, can be connected with hose, seamless steel pipe, shell. Specifications model size can be changed at will according to the machine and equipment, shell, seamless steel pipe, hose specifications, external thread. Run the rubber joint sprinkler system, turn off the rubber joint inlet and outlet gate valve, open the exhaust screw on the rubber joint shell, gradually open the inlet valve, wait until the water flow is smooth, then twist the exhaust screw, the liquid level is lower than the rubber joint, before starting the rubber joint, try to eliminate, remove steam, so that the inlet pipe and rubber joint are full of water. Check the direction of rotation, turn off the switch power circuit and observe the direction of rotation.

If there is no concrete antifreeze, the rubber joint is shut down when there is a risk of frost. When the rubber joint is out of use, the rubber joint and water need to be removed from the system. The pressurized rubber joint of the rubber joint should be checked on time for the operation of the rubber joint, as well as the operating pressure that may lead to overheating disassembly of the motor leakage, all operations and actual operations of cleaning/replacement of the screen (if equipped with one), as well as the disconnection time of the motor overload and the frequency of shutting down for rectification. The rubber joint is applied with reference to the characteristic categories of the bolded graph in type to prevent overheating and motor overload. Pay attention to whether there is noise when the bendable rubber flexible joint is running, and if there is any abnormality, it should be shut down immediately for inspection and immediate removal; cold-proof countermeasure rubber joints can be used in systems that have adopted cold-proof countermeasures for water. If rubber joints are installed in frost-prone areas, appropriate concrete antifreeze should be added to prevent the solution from freezing and causing harm to the rubber expansion joint.