The application of rubber joints in buried pipelines

May-23-15

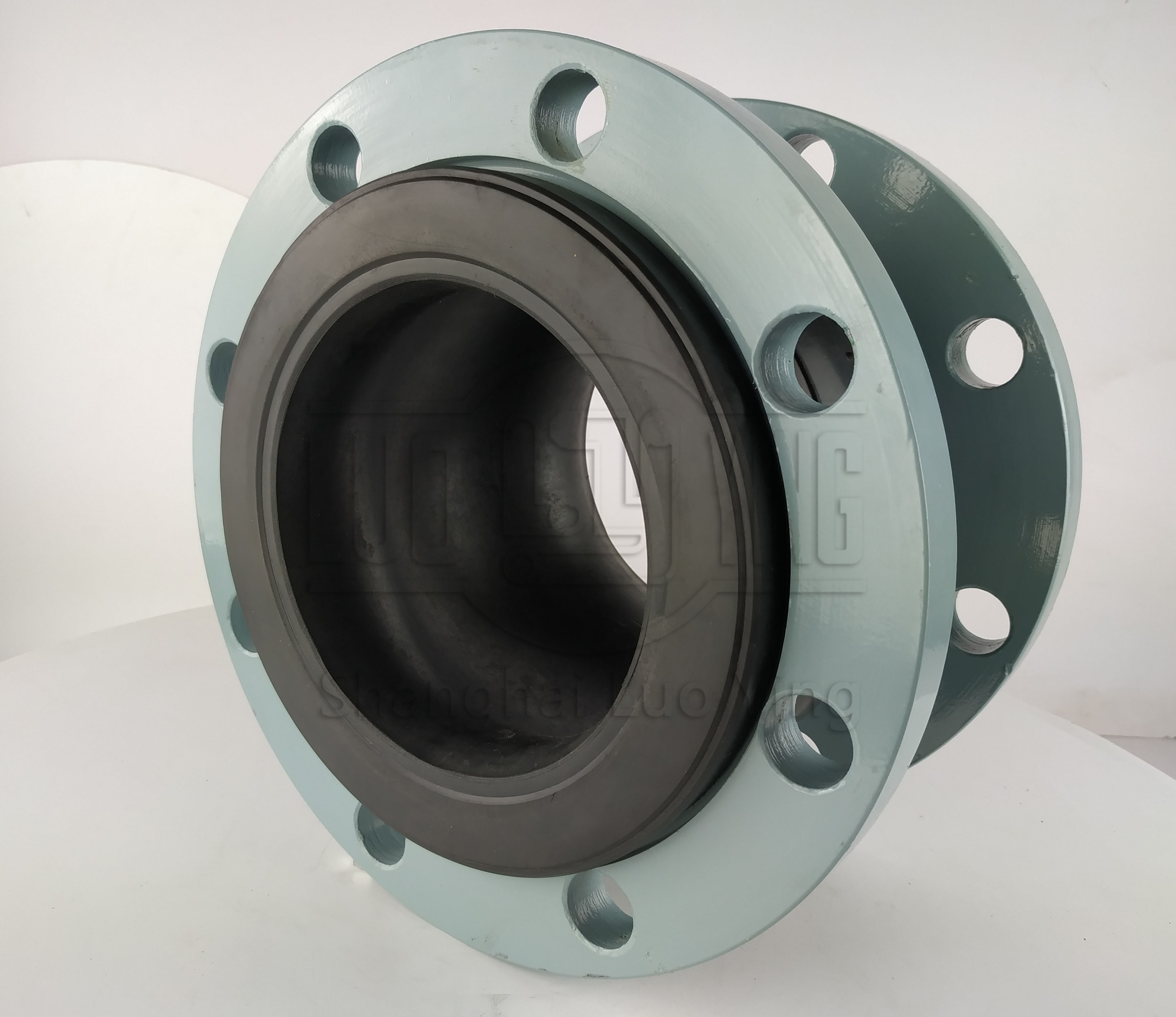

The application of rubber joints in buried pipelinesThe application of rubber joints in buried pipelines is very important. Rubber joints form a sealing structure by joining two semi-circular rings together and combining them into a joint, thus effectively reducing heat loss and noise transmission in the pipeline.

There are several other applications of rubber joints in buried pipelines as follows:

1 . Reducing pipeline vibration and noise: As buried pipelines need to cross roads, railroads and other public facilities, the pipelines will generate vibration and noise during transportation and use, and rubber joints reduce these noises through excellent sealing performance to improve the efficiency and comfort of pipeline transportation.

2 . Increase the connection strength of pipelines: In buried pipelines, the connection nodes of pipelines are very important, and rubber joints, as one of the parts to connect pipelines, can effectively increase the connection strength of pipelines and prevent pipelines from breaking and falling off.

3 . Extend the service life of pipeline: corrosion and wear of buried pipeline are important factors affecting the operation efficiency and life of pipeline, while the sealing performance and design of rubber joints can extend the service life of pipeline and reduce the frequency of pipeline maintenance.

The application of rubber joints in buried pipelines is very important, not only to reduce the heat loss and noise transmission in the pipeline, but also to increase the connection strength of the pipeline, extend the service life of the pipeline, and improve the transportation efficiency and comfort of the pipeline.