What are the types of axial type external pressure corrugated compensator?

Jul-23-17

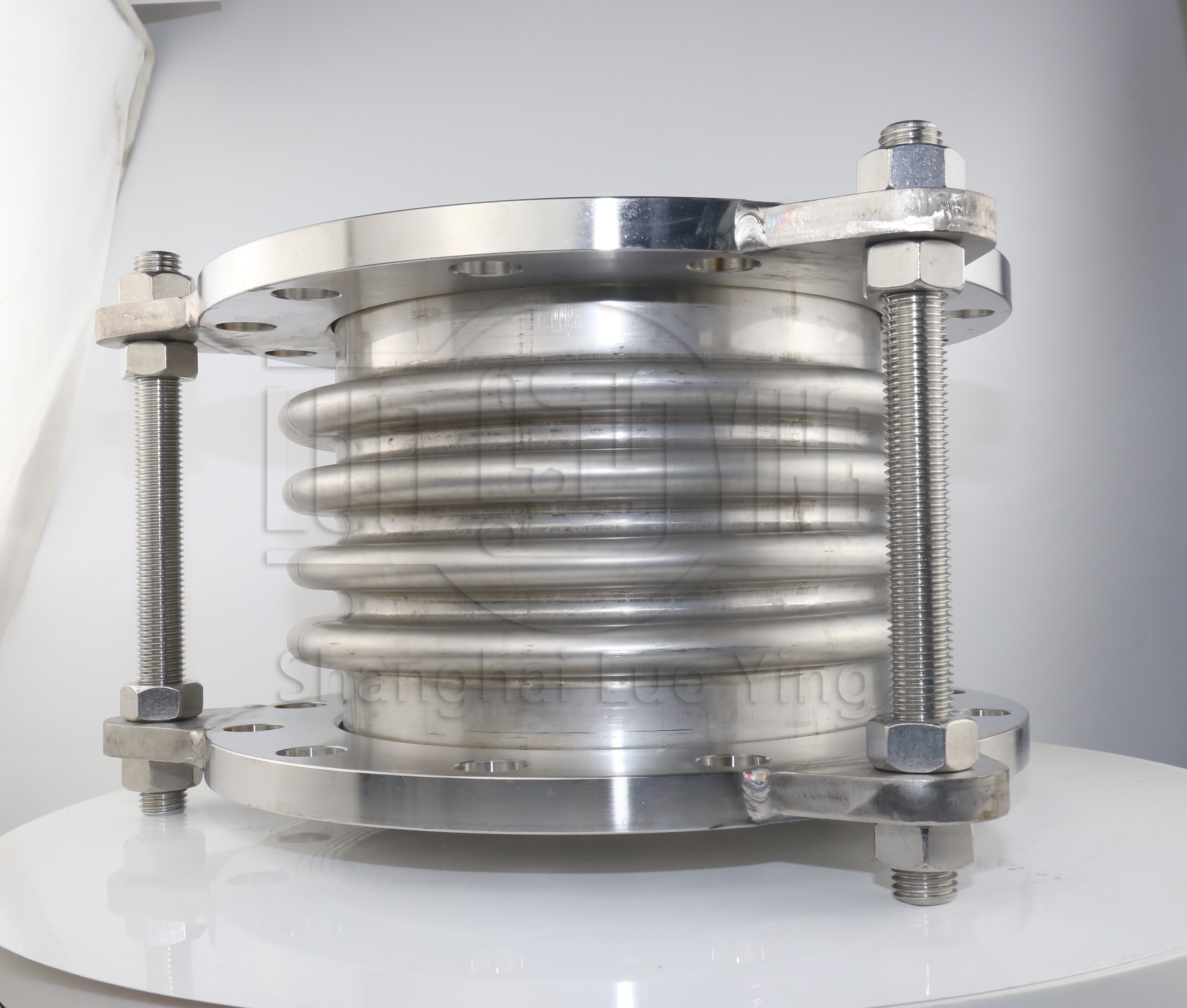

What are the types of axial type external pressure corrugated compensator?Axial type external pressure corrugated compensators, also known as axial expansion joints or bellows, are used in piping systems to absorb axial movement caused by thermal expansion, vibration, or other factors. These compensators consist of a series of corrugations that allow the bellows to flex and accommodate the axial movement. There are several different types of axial type external pressure corrugated compensators. In this article, we will discuss some of the common types.

1 . Hinged Type Compensator:

The hinged type compensator consists of two bellows connected by a hinge mechanism. This type of compensator allows for angular movement as well as axial movement. The hinge allows the compensator to flex in a controlled manner, accommodating both thermal expansion and angular displacement. Hinged type compensators are often used in applications where there is a need to absorb both axial and angular movement, such as in pipelines with offset or misaligned connections.

2 . Gimbal Type Compensator:

The gimbal type compensator consists of two bellows connected by a gimbal ring, which allows angular movement in multiple directions. The gimbal ring mechanism accommodates angular movement while maintaining the pressure containment capability. Gimbal type compensators are commonly used in applications where there is a need to absorb large angular movement while maintaining the integrity of the piping system.

3 . Universal Type Compensator:

The universal type compensator consists of two bellows connected by a ball joint mechanism that allows for axial, angular, and lateral movement. The ball joint mechanism provides flexibility in multiple directions, making it suitable for applications where there is a need to absorb movements in various planes. Universal type compensators are typically used in complex piping systems that experience multidirectional movement, such as in power plants or chemical processing facilities.

4 . Pressure Balanced Type Compensator:

The pressure balanced type compensator is designed to counterbalance the axial force generated by the internal pressure acting on the bellows. This type of compensator consists of two bellows with an internal pressure chamber connecting them. The pressure balanced design minimizes the axial thrust and reduces the forces exerted on the anchors and supports of the piping system. Pressure balanced compensators are often used in applications where there is a need to minimize the forces on the pipe supports or when the system has limited space for expansion.

The externally pressurized type compensator is designed to withstand high-pressure differentials. In this type of compensator, the bellows are designed to operate under external pressure, which balances the internal pressure acting on the bellows. The external pressure provides additional stability and compression resistance to the bellows, allowing them to withstand high-pressure differentials without deformation. Externally pressurized compensators are commonly used in applications where there is a need to compensate for high-pressure differentials, such as in steam or gas pipelines.

In conclusion, axial type external pressure corrugated compensators come in different designs to accommodate various types of movement and pressure differentials in piping systems. The selection of the appropriate compensator depends on the specific requirements of the application, including the magnitude and direction of movement, pressure differentials, and available space. Consulting with a qualified engineer or manufacturer is crucial to ensure the correct type of compensator is chosen for optimal performance and reliability.