How is the rubber reducer sealed?

Jul-23-17

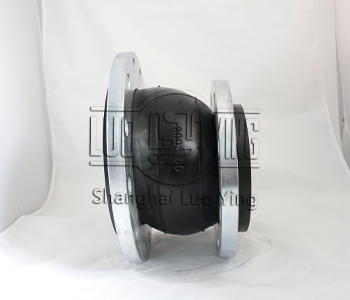

How is the rubber reducer sealed?Rubber reducers, also known as rubber expansion joints or rubber bellows, are commonly used in piping systems to absorb movement, vibration, and noise. They are designed to provide flexibility and compensate for misalignments, thermal expansion, and contraction. One essential aspect of rubber reducers is their sealing mechanism, which ensures a leak-free and secure connection. In this article, we will discuss the common methods used to seal rubber reducers.

1 . Flange Connection:

Flange connections are widely used to seal rubber reducers. The rubber reducer has flanges at each end that are bolted together with matching flanges on the adjoining pipes or equipment. The flanges are typically made of metal, such as carbon steel or stainless steel, and are designed to withstand the pressure and temperature of the application. The flanges are usually equipped with gaskets, such as rubber gaskets or PTFE (Polytetrafluoroethylene) gaskets, which are placed between the flange faces to create a seal.

The sealing mechanism in a flange connection relies on the compression of the gasket between the flanges. When the bolts on the flanges are tightened, the gasket is compressed, filling any gaps or irregularities between the flange faces. This compression creates a tight seal that prevents leakage. The choice of gasket material depends on the specific application, considering factors such as temperature, pressure, and the fluid being transported.

2 . Clamping Connection:

In some cases, rubber reducers may use clamping connections instead of flange connections. Clamping connections are typically used for smaller-sized rubber reducers or applications where a flange connection is not feasible. The clamping mechanism consists of metal bands or clamps that are tightened around the ends of the rubber reducer, compressing it onto the adjoining pipes or equipment.

3 . Union Connection:

In some instances, rubber reducers may use union connections, particularly in applications where quick disassembly or maintenance is required. Union connections consist of two halves that can be easily joined or separated. Each half has a mating surface that seals against the rubber reducer when joined together. The sealing mechanism in a union connection may vary, but it often involves O-rings or gaskets that create a seal when the two halves are tightly fastened.

The choice of sealing mechanism in rubber reducers depends on various factors, including the pressure, temperature, fluid compatibility, and installation requirements. It is crucial to consider the specific operating conditions and consult with a qualified engineer or manufacturer to select the appropriate sealing method and materials.

In conclusion, rubber reducers are sealed using different methods, including flange connections, clamping connections, and union connections. These sealing mechanisms, often combined with gaskets or sealing rings, create a leak-free and secure connection in piping systems. The choice of sealing method depends on the specific requirements of the application, and consulting with experts is essential to ensure proper sealing and optimal performance of the rubber reducer..