Analysis of corrugated metal hose operation working principle.

Jul-23-24

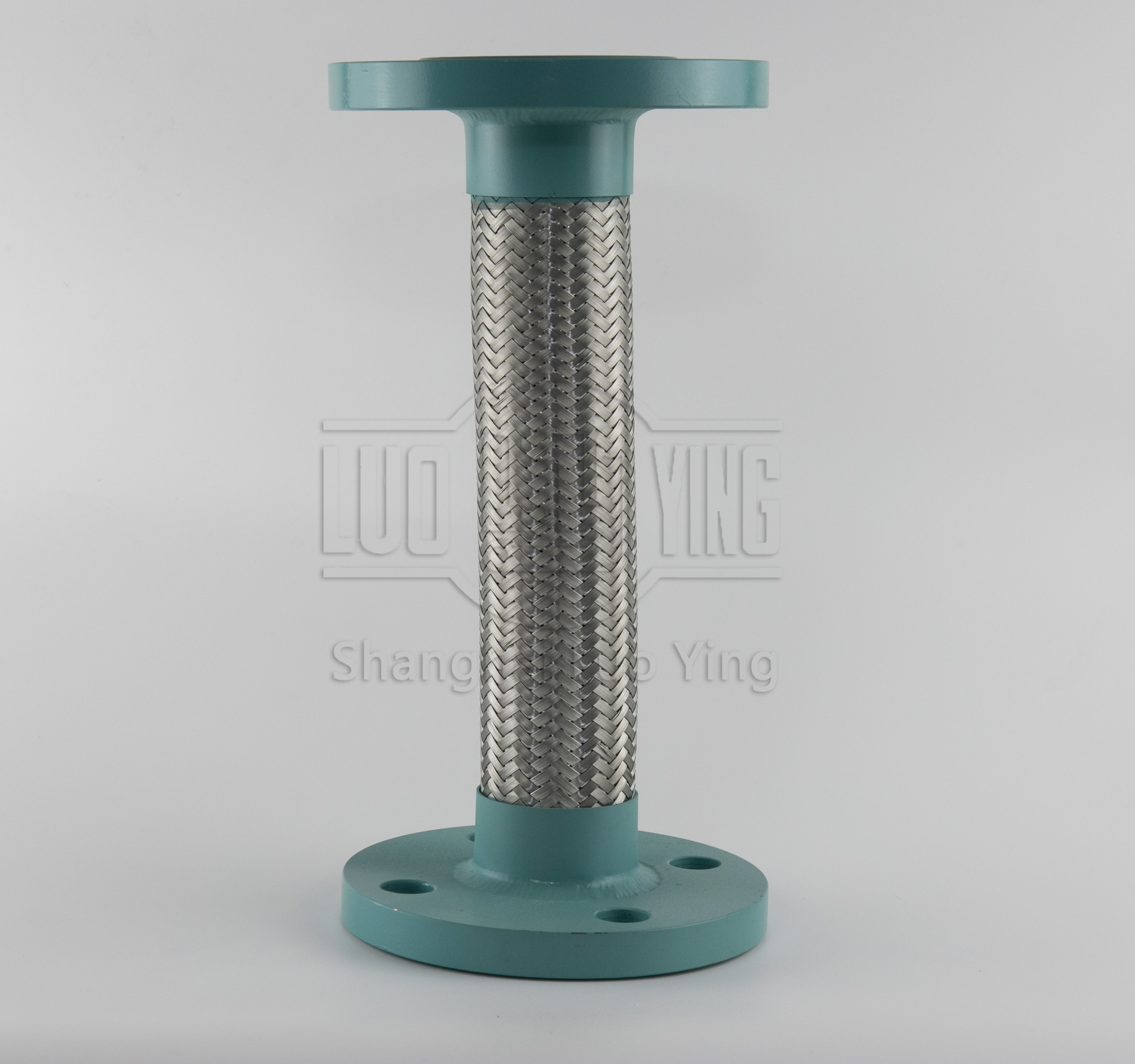

Analysis of corrugated metal hose operation working principle.Corrugated metal hoses are widely used in various industries for their flexibility, durability, and ability to withstand high pressures and temperatures. This article aims to provide an analysis of the working principle behind the operation of corrugated metal hoses.

The design of corrugated metal hoses is based on a series of convolutions or corrugations along the length of the hose. These corrugations act as flexible joints, allowing the hose to bend and flex without compromising its strength or integrity. The corrugations are typically formed through a process of cold rolling or hydraulic forming.

The flexibility of corrugated metal hoses is achieved through the shape and design of the corrugations. The convolutions create a series of ridges and valleys that allow the hose to bend and flex in multiple directions. This flexibility enables the hose to navigate around obstacles, curves, or tight spaces, making it a versatile solution for various installations.

Furthermore, the corrugated structure of the hose enhances its resistance to external forces, including pressure and torsion. The convolutions provide additional strength and rigidity, allowing the hose to withstand high pressures and maintain its shape. This makes corrugated metal hoses suitable for applications requiring the transportation of liquids, gases, or even solids under challenging conditions.

To ensure the proper functioning of corrugated metal hoses, various factors should be considered. The selection of the appropriate materials is crucial, taking into account the specific applications, temperature ranges, chemical compatibility, and environmental conditions. Stainless steel is a common choice due to its excellent corrosion resistance and durability.

Proper installation is also critical to the operation and longevity of corrugated metal hoses. The hoses should be installed with sufficient clearance to allow for their full range of motion. Factors such as the bending radius and the number of bends should be considered to prevent excessive stress on the hose. Adequate support and clamping are necessary to prevent sagging, vibration, or excessive movement during operation.

In conclusion, the working principle of corrugated metal hoses relies on their flexibility and ability to compensate for thermal expansion, vibrations, and dynamic forces within a system. The corrugations in the hose allow for bending and flexing while maintaining strength and resistance to external forces. Proper material selection, installation, and maintenance are essential to ensure optimal performance and longevity. Corrugated metal hoses play a crucial role in various industries, providing a reliable and efficient solution for the transportation of fluids or gases under challenging conditions.