Matters needing attention for disassembly of rubber expansion joints with limits.

Jul-23-25

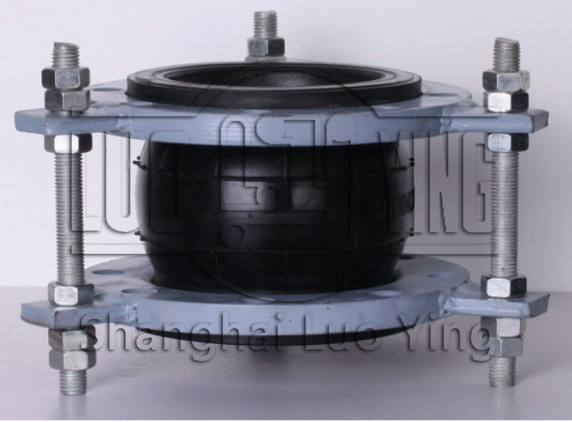

Matters needing attention for disassembly of rubber expansion joints with limits.Rubber expansion joints are commonly used in piping systems to absorb vibration, reduce noise, and compensate for thermal expansion and contraction. Over time, these joints may require disassembly for maintenance or replacement. However, disassembling rubber expansion joints with limits requires careful attention to avoid damaging the joints or the surrounding components. In this article, we will discuss the matters needing attention for the disassembly of rubber expansion joints with limits.

Safety Precautions: Before disassembling rubber expansion joints, it is important to take proper safety precautions. This includes wearing appropriate protective gear like gloves and goggles to protect against any potential hazards. Also, ensure that the system is depressurized and isolated before beginning the disassembly process to prevent any unexpected release of media or pressure.

Document the System: Before disassembling the rubber expansion joint, it is recommended to document the system. Take detailed photographs or notes of the joint, its location, and any associated piping or fittings. This documentation can be helpful during reassembly, ensuring that the joint is correctly installed and aligned.

Inspect the Joint: Before disassembling, visually inspect the rubber expansion joint for any signs of damage or wear. This includes looking for cracks, tears, bulges, or any other visible defects. If any issues are detected, it is important to assess whether the joint can be safely disassembled or if it requires immediate replacement. Disassembling a compromised joint could lead to further damage or failure.

Proper Tool Usage: Ensure that appropriate tools are used during the disassembly process. Improper tools or excessive force can cause damage to the joint or surrounding components. Follow the manufacturer's recommendations for the type of tools to use, such as wrenches or pliers specifically designed for the disassembly of rubber expansion joints.

Clean Work Area: Maintain a clean work area during the disassembly process. Remove any debris, oil, or other contaminants that may pose a safety risk or interfere with the disassembly. Keeping the work area clean will also help prevent any foreign materials from entering and potentially damaging the joint during reassembly.

In conclusion, disassembling rubber expansion joints with limits requires attention to safety, following manufacturer's instructions, and taking necessary precautions. Proper tool usage, inspection of the joint, and documenting the system are also essential. By following these matters needing attention, the disassembly process can be carried out effectively without causing any damage to the joint or other components.