Bidirectional Directly Buried Corrugated Compensator Technical Knowledge Sharing.

Jul-23-28

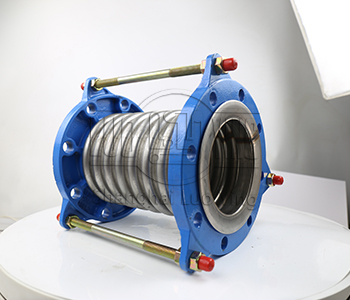

Bidirectional Directly Buried Corrugated Compensator Technical Knowledge Sharing. Bidirectional directly buried corrugated compensators, also known as expansion joints, are crucial components in piping systems that help to absorb thermal expansion, vibration, and movement. In this article, we will share technical knowledge about bidirectional directly buried corrugated compensators, including their design, installation, and advantages.

Design: Bidirectional directly buried corrugated compensators are designed to withstand axial, lateral, and angular movements in the piping system. The compensator consists of a corrugated bellows made of stainless steel, which provides flexibility and durability. The bellows are often coated with a protective layer, such as epoxy or polyurethane, to resist corrosion and extend their service life.

Installation: The installation of bidirectional directly buried corrugated compensators should be done by qualified and experienced professionals. The compensator is typically installed in a shallow trench directly in the ground. Adequate support and backfill material should be used to ensure proper alignment and stability of the compensator. It is essential to follow the manufacturer's guidelines and specifications during the installation process to avoid any potential issues.

Maintenance: Regular inspection and maintenance are essential to ensure the optimal performance of bidirectional directly buried corrugated compensators. Inspections should include checking for any signs of corrosion, wear, or damage to the bellows and protective coatings. The surrounding area should also be inspected for any settlement or soil movement that could affect the compensator. If any issues are identified during inspections, appropriate actions should be taken to repair or replace the compensator.

Advantages: Bidirectional directly buried corrugated compensators offer several advantages in piping systems. Firstly, they provide efficient compensation for thermal expansion, reducing stress on the pipeline and extending its service life. Secondly, they help to minimize vibrations, which can prevent damage to the piping system and adjacent structures. Additionally, the directly buried installation eliminates the need for above-ground supports, making the system more aesthetically pleasing and reducing potential safety hazards.

Applications: Bidirectional directly buried corrugated compensators are widely used in various industries, including petrochemical, power generation, water supply, and HVAC systems. They are commonly used in underground pipelines, buried transmission lines, and areas where above-ground space is limited. The compensators are designed to withstand high pressures and temperatures, making them suitable for both residential and industrial applications.

In conclusion, bidirectional directly buried corrugated compensators play a vital role in managing thermal expansion, vibration, and movement in piping systems. These compensators offer flexibility, durability, and efficient compensation, reducing stress on the pipeline and enhancing its performance and longevity. Proper design, installation, and maintenance are essential to ensure the optimal functioning of bidirectional directly buried corrugated compensators.