Rubber Expansion Joint Models and Features.

Nov-23-03

Rubber Expansion Joint Models and Features.Rubber expansion joints are flexible connectors that are commonly used in piping systems to absorb movements, vibrations, and stress They provide a cost-effective solution accommodate thermal expansion and contraction, reduce noise and vibration, and compensate for misalignment. this article, we will discuss different rubber expansion joint models and their features.

Single Sphere Rubber Expansion Joint: The single sphere rubber expansion joint is the most common and simplest model. It consists of a rubber sphere that is reinforced with a fabric or metal body. The single sphere design allows axial, lateral, and angular movements to be absorbed while providing flexibility to the piping system. These expansion joints are suitable for a wide range of applications and can handle moderate pressure and temperature variations.

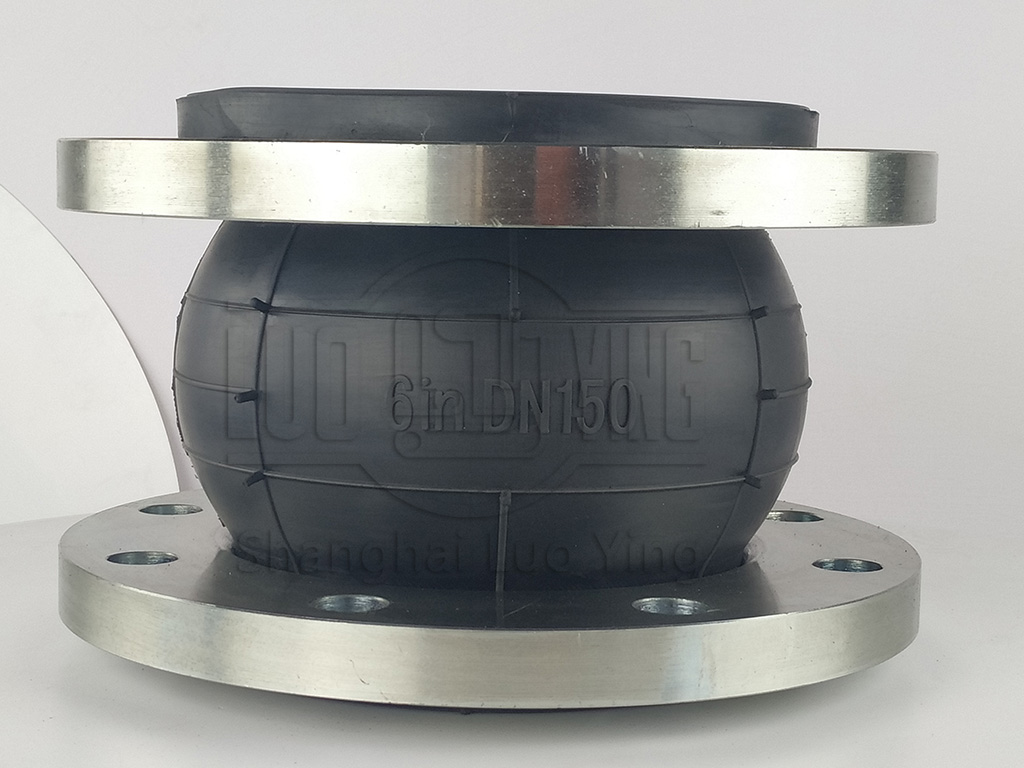

Double Sphere Rubber Expansion Joint: Double sphere rubber expansion joints have two interconnected rubber spheres that are separated by a reinforced body. This design allows even higher flexibility and greater movement absorption capabilities compared to the single sphere joint. Double sphere expansion joints can handle higher pressures, temperatures, and provide better resistance to vibration and noise transmission. They are commonly used in HVAC systems, water treatment plants, and industrial applications.

Elbow Rubber Expansion Joint: Elbow rubber expansion joints are specially designed to accommodate angular movements in piping systems. They have a curved shape that allows them to be installed in locations where pipes change direction. Elbow expansion joints can absorb both axial and angular movements, ensuring the integrity and flexibility of the system. These joints are commonly used in power plants, HVAC systems, and water treatment facilities.

Tapered Rubber Expansion Joint: Tapered rubber expansion joints are designed for applications where the diameter of the pipes changes. They have a larger diameter on one end and gradually taper down to a smaller diameter on the other end. Tapered joints allow for smooth transition and compensation of diameter changes, reducing stress and preventing leakage at pipe connections. They are commonly used in pumps, compressors, and other equipment installations that involve varying pipe sizes.

Features of Rubber Expansion Joints:

Material: Rubber expansion joints are typically made from high-quality elastomers such as natural rubber, EPDM, neoprene, or nitrile. These materials provide excellent flexibility, chemical resistance, and durability.

Reinforcement: Expansion joints are reinforced with fabric or metal materials to enhance their strength and stability. Fabric reinforcement provides flexibility, while metal reinforcement adds strength and pressure resistance.

Flange Options: Rubber expansion joints are available with a variety of flange options, including standard ANSI flanges, DIN flanges, or custom-made flanges to suit specific system requirements.

Pressure and Temperature Ratings: Expansion joints are designed to handle specific pressure and temperature ratings. It is essential to choose the appropriate joint that can withstand the conditions in the piping system.

Movement Absorption: Rubber expansion joints can absorb different types of movements, including axial, lateral, angular, and torsional. The amount of movement absorption depends on the design and model of the expansion joint.

In conclusion, rubber expansion joints come in various models and offer different features to accommodate the needs of piping systems. Whether it is a single sphere, double sphere, triple sphere, elbow, or tapered rubber expansion joint, each model has its unique benefits and applications. By selecting the appropriate expansion joint and considering its features, system designers and engineers can ensure the efficient and reliable operation of piping systems.