Luoying tells you the causes of aging of rubber expansion joints and preventive measures.

Aug-22-26

Any product has its life and service life, and rubber joints are no exception. The aging of rubber soft joints has always been one of the problems troubling users, so what are the reasons and preventive measures for aging of rubber joints?1.An important reason affecting the use of rubber joints is the oxidation by pressure and air during use. In the process of processing, storage and use of rubber and its products, the physical and chemical properties and mechanical properties of rubber gradually deteriorate and evolve into no use due to the combined effect of internal and external factors. This change is called rubber aging. Surface manifestations are cracks, viscosity, hardening, softening, chalking, discoloration, mold, etc. Therefore, flexible rubber joints should be checked regularly during use, and some of them should be regularly maintained and replaced if their service life exceeds and aging is serious.

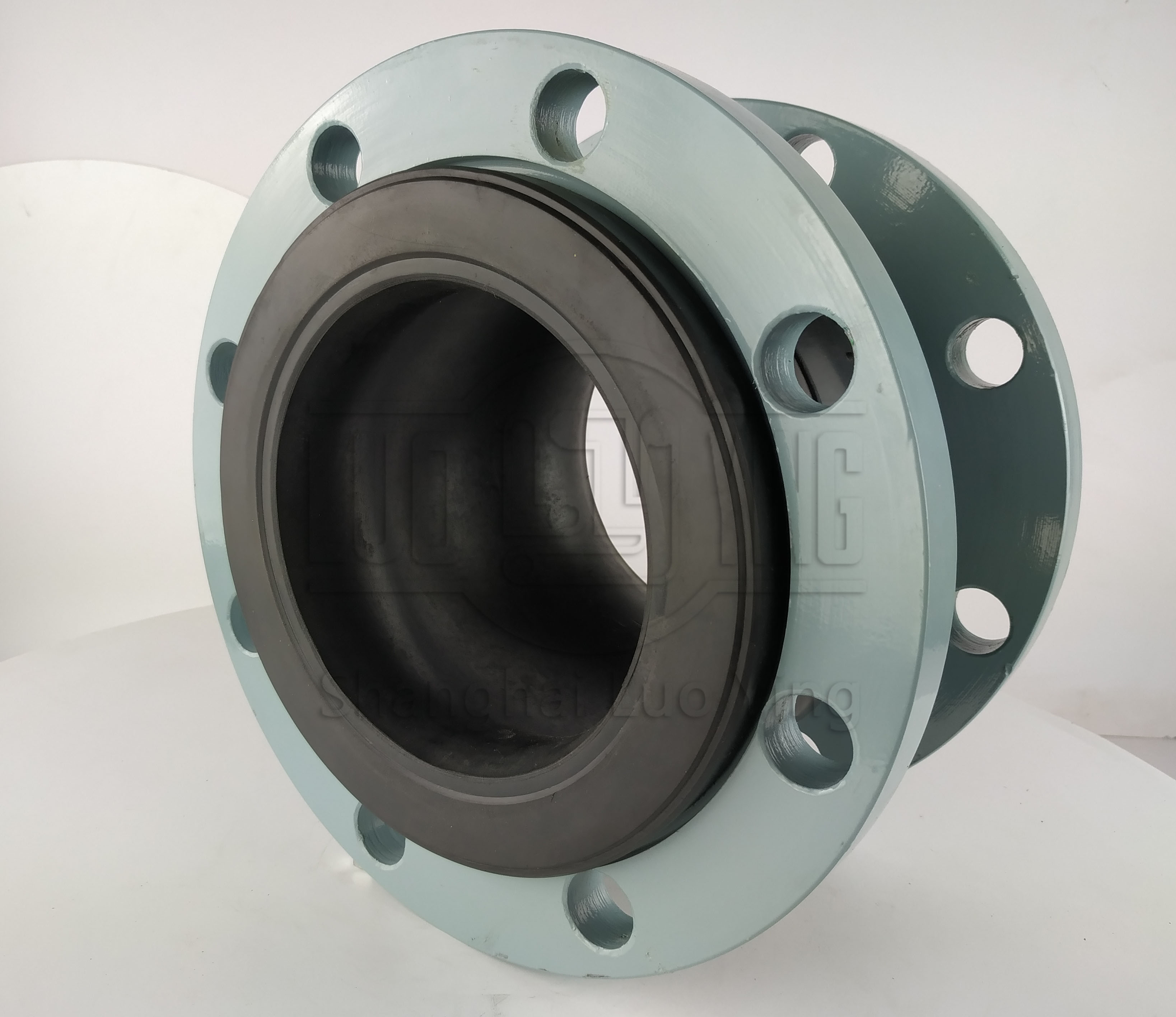

2. Pay attention to the method of installation to extend the service life of rubber joints. When installing rubber joints, they should be kept in their natural state and should not be artificially deformed during installation. This will lead to early damage of the product and weakening of the use effect. If the product is installed at the near end of the pump outlet or the corner of the pipeline, as well as high pressure, high rise building suspension use, the pipeline has fixed support or fixed support, the stress of fixed support and fixed support is greater than the axial force, otherwise the rubber joint should be installed with anti-pull-off limit device.

3. When installing the grooved rubber joint, the enhancement of both ends of the sphere should be stuck in the flange groove to prevent the sphere from falling off with the flange under the pressure of the pipeline. When tightening the bolts, tighten the symmetrical bolts at one time to ensure that the sphere and the flange fit completely. When the rubber joint is connected to the flanged pipe channel, the extra bolt rod should be extended to one end of the pipe flange to prevent the arching part of the rubber joint from being squeezed or punctured when the pressure expands. Screws at each end are tightened symmetrically with pressure so that all bolts are loosened and tightened consistently. In places where the use conditions are harsh, spring washers should be added in addition to flat pads to prevent the nuts from loosening.

As rubber soft joints are subject to pressure and air oxidation during use, this is an important reason that affects the use of rubber joints. During the processing, storage and use of rubber and its products, the physical and chemical properties of rubber are caused by internal and external factors. The performance and mechanical properties gradually deteriorate and then lose their use value, called rubber aging. The surface has cracks, viscosity, hardening, softening, chalking, discoloration and mildew.

The process of ball includes gas mold and hard mold. Gas molds have a very smooth balloon interior with mold seams inside the ball. The old processing technology eliminated in the past has aging defects, and the gas film uses a new processing process that can withstand high pressure and long service life. Not reached the hardness of the lower rubber joint ball, light extrusion will produce depression. As a result, the length of the rough ball is shortened and it is difficult to restore the original shape. It should be noted that NBR rubber has good oil resistance and has a tendency to reduce oil resistance with other polymers. Therefore, flexible rubber joints should be checked regularly during use. After years of use, the aging is more serious. Regular maintenance and replacement. Attention should also be paid to the method of installation to prolong the service life of rubber joints.