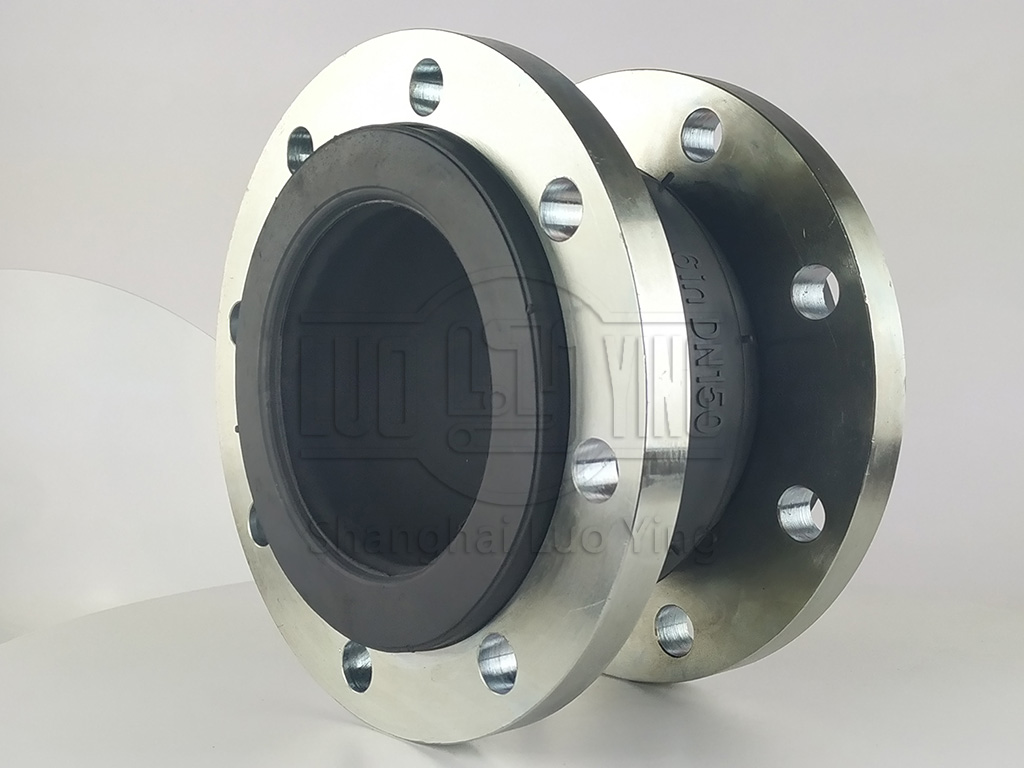

Analysis of the causes of water seepage of rubber expansion joint spheres.

Sep-22-17

The installer does not install in accordance with the correct installation method, and it is strictly prohibited to stretch with super displacement and keep away from sharp and pointed objects, so as not to cause damage to the spheres and cause water leakage of the rubber expansion joint.When the pipeline displacement is greater than the compensation amount of the expansion joint, the number of joints should be increased parallel displacement. It is strictly forbidden to adjust the pipeline over the difference, so that the joint is in the limit around the bending displacement and deviation state, and shall not exceed the limit.

Welded flange no for the use of the correct fittings, butterfly valve special hair flange.

Prevent water leakage mainly pay attention to the type selection and installation.

Rubber expansion joint as a rubber product, has a certain amount of expansion, however, the expansion of rubber products is very limited, special media such as: oil, acid and alkali, high temperature and other aggressive and hard texture, should be based on their own working environment, connection methods, compensation amount to choose the corresponding special resistant materials or special models of rubber expansion joint, not blindly string with or general.

In the process of our installation and operation, due to the thin and uniform wall, if the laying distance is long, the middle section of the tube will rupture under its own pressure, or arbitrarily be stretched or compressed, which often also causes damage to the lato or sphere, resulting in the phenomenon of water leakage.