Installation position of extended flexible waterproof casing.

Sep-22-20

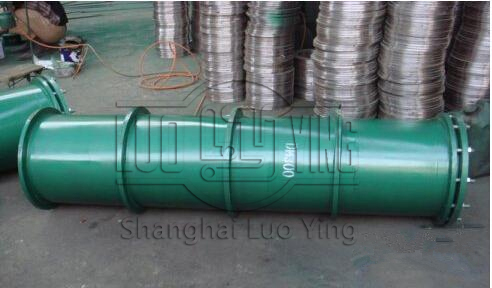

In order to better protect the software of the piping system through the wall from harm, waterproof casing equipment is set at the pipeline through the wall, also known as through the wall pipe, steel casing, extended flexible waterproof casing, etc.. Extended flexible waterproof casing the pipe is used in reservoirs, human defense walls and other areas with vibration or strict waterproofing regulations, the deviation is allowed to change after the pre-installed parts. Wherever the use of extension flexible waterproof casing, its function is to better maintain the pipeline, to ensure the normal and reliable operation of the pipeline system software.

1. Rigid slender flexible waterproof casing is a seamless steel pipe with wing ring, connected to the wall, used for general piping through the wall, which is conducive to wall waterproofing; in addition to the external wing ring, lengthened flexible waterproof casing also has a retaining ring in the internal structure, etc. Necessary piping, such as when the pipeline connected to the submersible pump through the wall.

2. From the outside, the rigid extension flexible waterproof casing consists only of steel waterproof casing and wing ring, and the structure is simple. The key to lengthening flexible waterproofing casing is: flange waterproofing casing seal ring flange clutch pressure plate wing ring foot bolt and nut structure complex.

3. When the wall of the building that does not need to withstand the vibration and expansion and deformation of the pipeline using water hardened lengthened flexible waterproof casing, generally applicable wall thickness of 200mm, lengthened flexible waterproof casing is mainly applicable to ground vibration. Provisions to withstand the vibration of the pipeline and expansion and contraction deformation of the building wall, and strict waterproofing provisions, the general applicable wall thickness of 300mm.

4 . Rigid and slender flexible waterproof casing is divided into: Type A Type B Type C. Type A is applicable to seamless steel pipes, Type B is applicable to cast iron drainage pipes and ductile iron pipes. The elongated flexible waterproof casing is divided into: Type A for Type B, Type A for internal and external walls of buildings, Type B for building walls.

5 . Rigid extended flexible waterproof casing in the seamless steel pipe outside welded a water stop wing ring, extended flexible waterproof casing in the seamless steel pipe outside welded three wing rings, four screw fasteners on one side, the inside welded. The stopper plus the seal ring, the outer side of the flange, 4 foot bolts on both sides, the top of the head welded seamless steel pipe, after the installation of the pipe, install the flange and tighten the screws. The tighter the seal ring, the more impermeable it is, usually used in places with high waterproof requirements, such as the drainage inlet of a reservoir.

6 . Only waterproof provisions, the use of rigid expansion waterproof casing; when both waterproof provisions, but also anti-vibration, anti-migration provisions, the use of lengthening flexible waterproof casing; from the above, it can be seen that there are differences between the above two structures. For the same size of the two extended flexible waterproof casing, extended flexible waterproof casing is more complex, and therefore more expensive.