How to judge the good and bad of LUOYING rubber expansion joint?

Sep-22-19

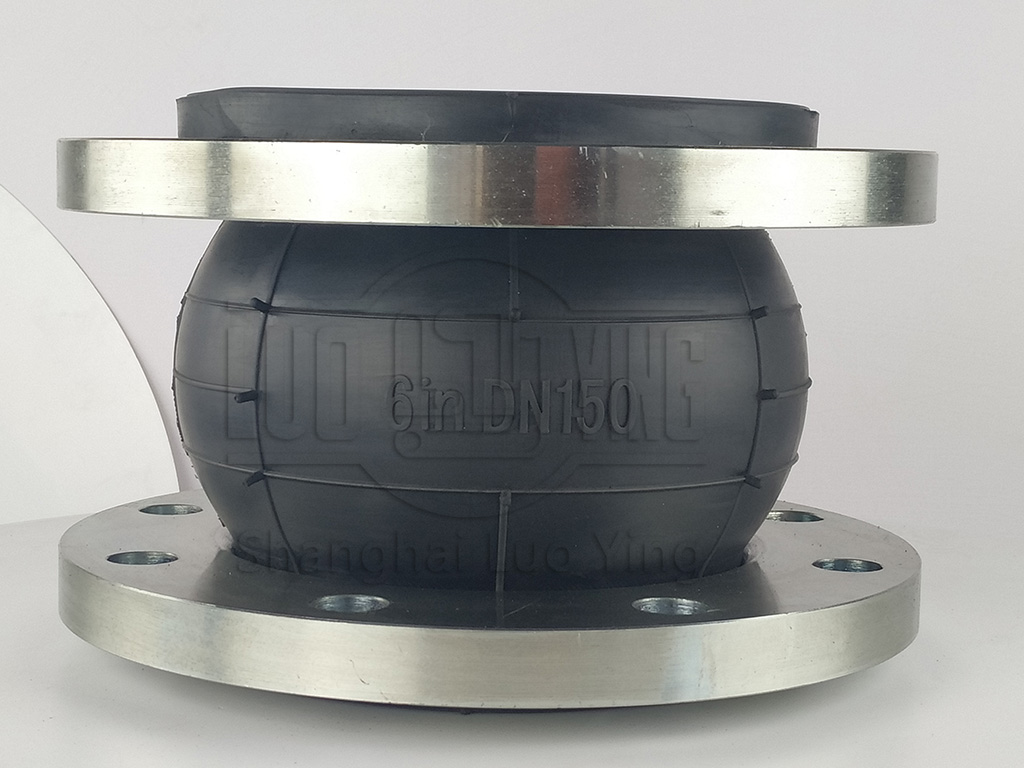

External inspection, through the tape measure, caliper, thickness tester and other equipment on the rubber expansion joint flange specification size check, flange surface cutting and chisel, to confirm whether the content with the contract.First look at the color of the rubber, particularly bright is not necessarily a good rubber sphere, good rubber sphere is of course black with bright, a natural rubber color.

Touch by hand, the appearance of poor quality rubber expansion joints will have the appearance of bubbles, not smooth, there are broken places, not good rubber spheres, especially look at the inside of the rubber sphere, to ensure smooth. Smooth sphere can ensure the smooth passage of the medium, not easy to stay, not easy to cause corrosion of the sphere.

Pressing, rubber expansion joints of a wide variety, depending on the type of rubber material and thickness is not the same, usually small rubber spheres are easier to press, but feel flexible, poor quality rubber made of rubber expansion joints pressed up to feel harder, no high-quality rubber soft.

Pulling, manufacturers in the production of rubber expansion joint some spheres will be left on the surface of some contacts, users can pull these contacts in the selection process to identify the quality of rubber, pulling elasticity constantly, ductility, indicating that the use of good quality rubber, if a pull on the break more slack, indicating that the rubber material is poor, rubber joint product quality is not good.