The causes and measures of cracks in rubber expansion joints.

Oct-22-15

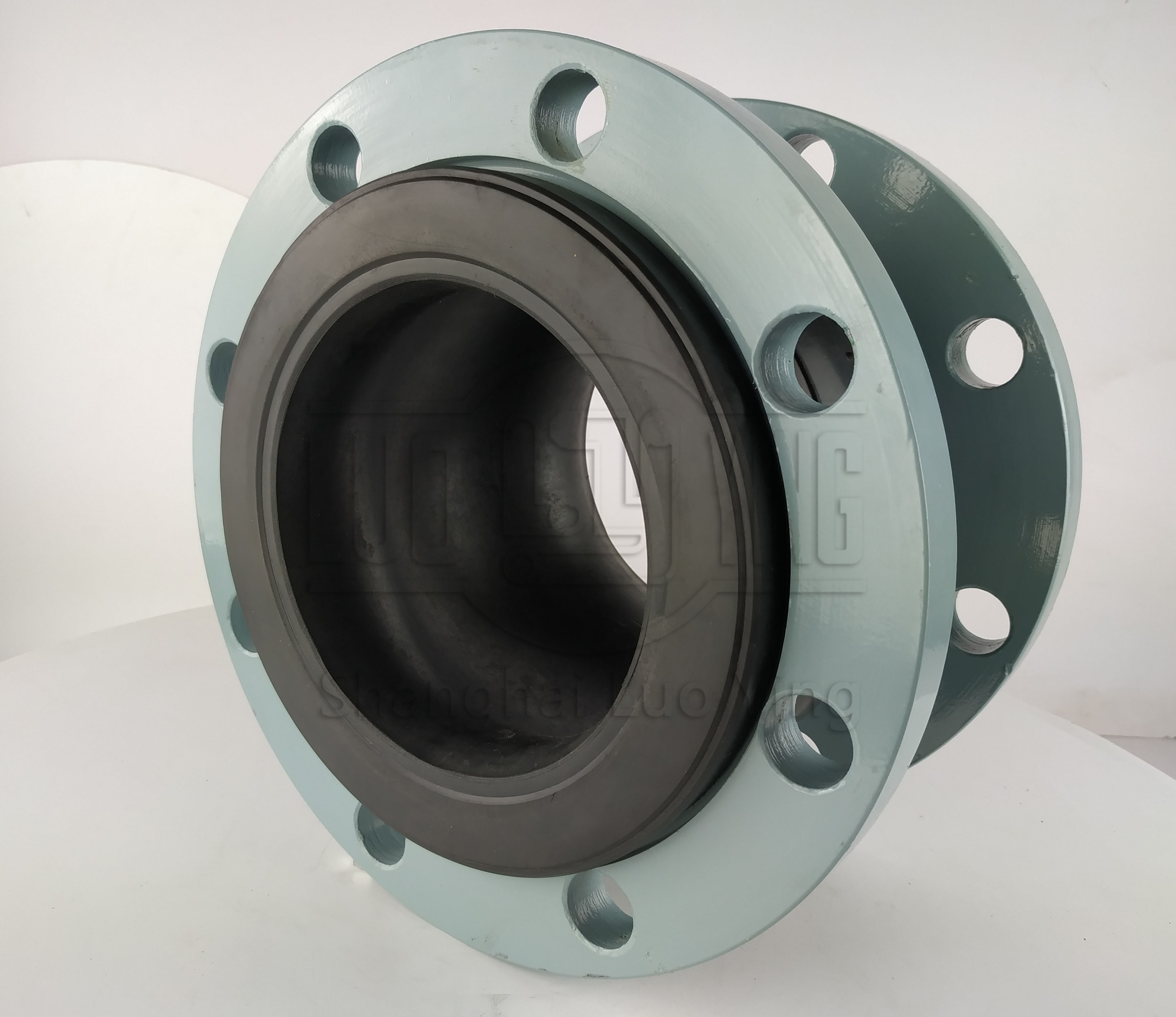

Because it is a rubber product, when it is used in high temperature, high pressure and other environments, the rubber will easily produce deformation, and when the pressure inside the rubber expansion joint increases, the surface of the sphere will easily produce cracks.The length of the link used in the process is not enough, forcibly beyond the link length, arbitrarily expand the shrinkage range may also crack.

Rubber expansion joint production process, if each compound is wrongly weighed, multi-weighed, under-weighed, missed weighing and other problems, compound dispersion is uneven, the local compound concentration is too large will precipitate out of the surface to cause cracking, so the rubber mixing process, the need to strictly follow the established production process, always master the production process, strict control of roll temperature, to avoid local cracking of rubber expansion joints.

Many of the pipeline rubber expansion joints exposed to the sun for a long time in the outdoors, will form rubber expansion joints of rubber aging, rubber expansion joint spheres show varying degrees of cracking.

Working pressure of the pipeline rubber expansion joint to be installed with a limit device, the bend in the pipeline can add a fixed bracket. Check whether the bolts of the flange of the rubber expansion joint are tightened, if not tightened will cause rubber expansion joint leakage and rubber sphere wear more serious.

Rubber expansion joint should be regularly checked by maintenance personnel and replaced immediately if problems are found. If not immediately disassembled and replaced, the rubber expansion joint will reflect the physical expansion of the rubber expansion joint in a short period of time under the working pressure of the pipeline, and the slight cracks on the surface of the rubber expansion joint will slowly break and expand, and then the plastic air oxidizes.

The condition of serious rubber expansion joint is to replace, and adopt appropriate protection measures to prevent rubber expansion joints continue to be exposed to the sun, such as rubber expansion joints covered with plastic bags or plastic film, as far as possible to postpone the moment of rubber expansion joint cracking aging, extending the operating life of rubber expansion joints.