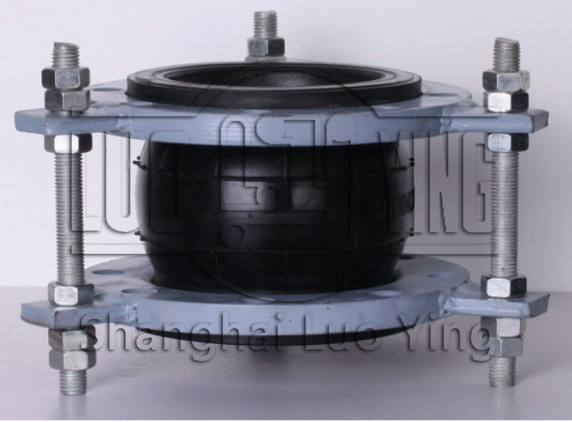

Why rubber joints are designed to be spherical

Oct-22-31

As we all know, rubber joints are widely used in the industrial field. The reason why it is favored is that it has the following characteristics.1.Corrosion resistance: The rubber part of the joint can be made of different rubber according to the different mediums to be passed, no matter it is common water, or sewage of special nature, or various oils, or even various gases, such as gas and steam, can be passed from it.

2.Resistant to high pressure: the joint gel is vulcanized and formed, with high internal density and good pressure-bearing performance.

3.It can move in four directions and absorb vibrations: Because of the natural characteristics of the rubber body, the rubber joint has good elasticity and can easily accomplish compression, elongation, lateral displacement and angular offset, which prevents the damage caused by thermal expansion and contraction and pipeline displacement to the overall pipeline during the use of the pipeline.

The rubber joint is designed as a sphere precisely because of its third characteristic, because in its working environment it may be required to move in all directions according to the needs of the work, which is not available for straight-walled rubber pipes, because straight-walled pipes will inevitably cause damage regardless of stretching, compression or transverse displacement.

The sphere design, on the other hand, reduces the damage to the pipe and enhances the flexibility and service life of the joint.