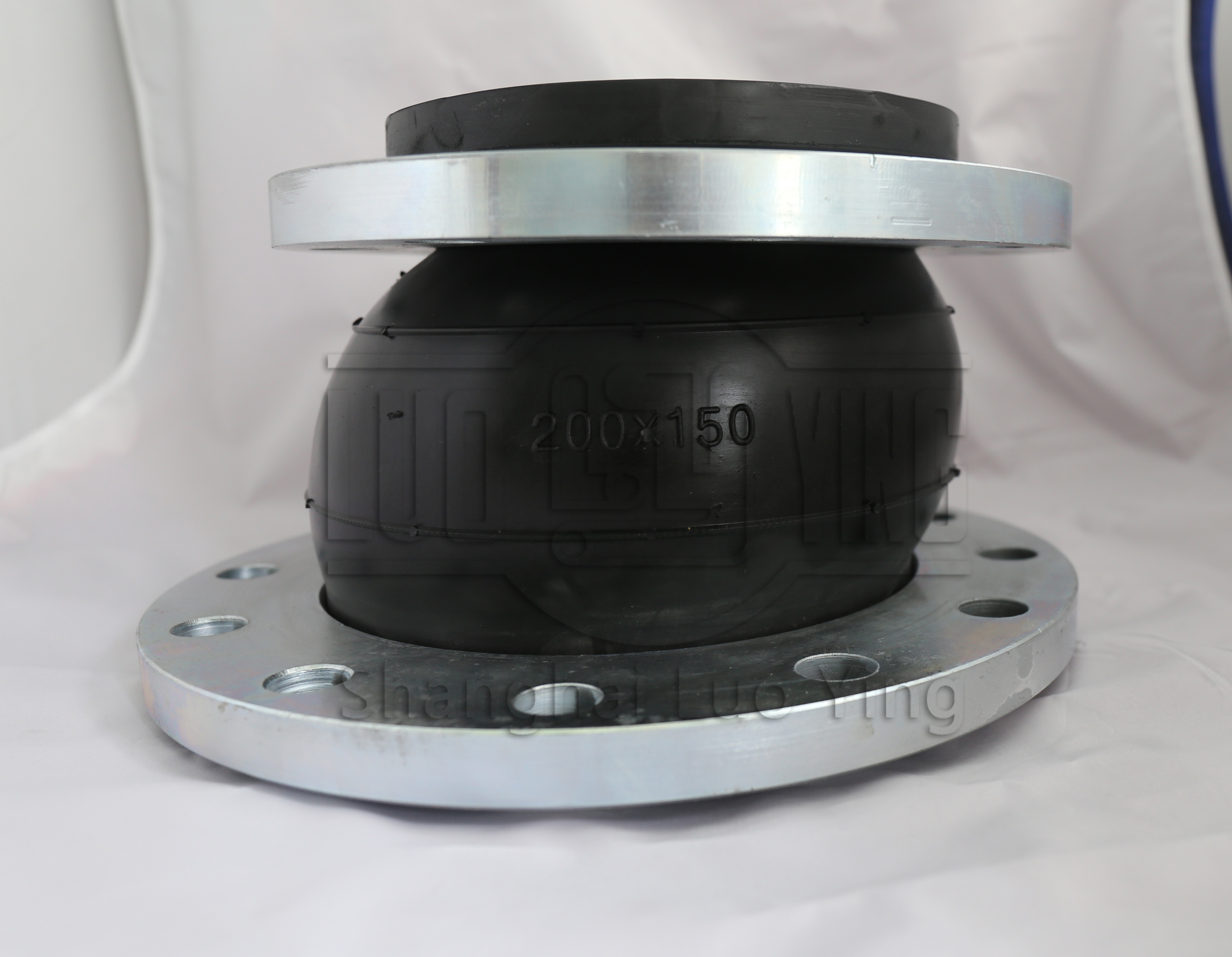

Bendable Concentric Reducing Rubber Expansion Joint

Nov-22-14

Bendable rubber expansion joint manufacturer, reducer rubber expansion joint is a key fitting for pipeline, bendable rubber expansion joint is a very popular rubber soft joint. Flexible rubber joints are made by different materials of rubber, and the effect of isolation between different materials. Among the bendable rubber joint materials are mainly EPDM rubber and high-density polyethylene two, bendable rubber expansion joint is divided into single sphere and double sphere two categories, single sphere is mainly made of a single layer of high-quality film by vulcanization, extrusion molding; double sphere is mainly made of rubber by vulcanization, extrusion molding. Because the rubber itself has excellent elasticity, shock absorption, compensation vibration function, so it is a bridge bearing, petrochemical machinery manufacturing essential one of the important supporting products. It can be widely used in various pipelines and equipmentsThe structure is transformed from common rubber joints. It is divided into concentric reducer rubber joint and eccentric reducer rubber joint, which is especially suitable for the installation of pumps and pipes with different diameters, but not for parallel connection. The product has all the performance advantages of other rubber joints, with the advantages of high pressure resistance, good elasticity, large deformation, vibration and noise reduction, etc. It saves the cost of pipeline arrangement and labor and material resources. Pipeline pump eccentric reducer diameter rubber joints are used to prevent cavitation, and the large and small heads of the pump inlet should usually be installed flat.

Bendable rubber joints should be installed in a position for easy inspection and maintenance so as not to affect the service life of rubber joints. For corrosive media, it should be installed in a corrosion-resistant device to prevent corrosion from invading the inside of the rubber joint and affecting the service life. For media with high temperature, such as too much sulfide, certain measures should be taken to prevent the rubber joint from thermal expansion and contraction. If the rubber joint is deformed after long-term use, its installation position can be adjusted appropriately and its performance can be checked frequently to see if it meets the requirements. In normal operation, rubber joints must work under certain pressure. When the design pressure of the pipeline exceeds the specification of the rubber joint, a check valve should be added at the connection.