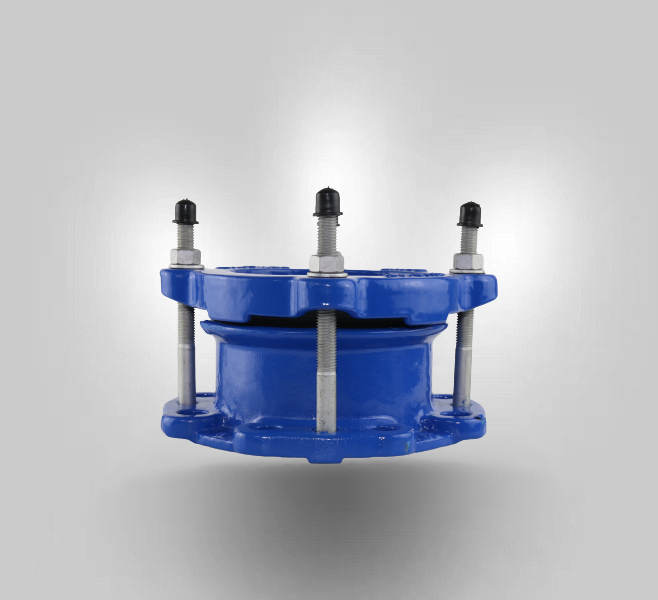

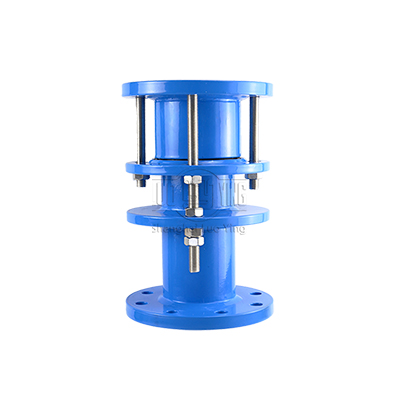

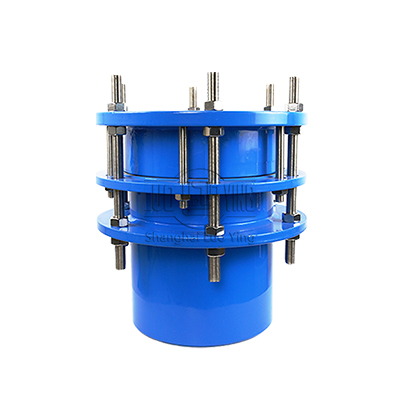

Dismantling joints

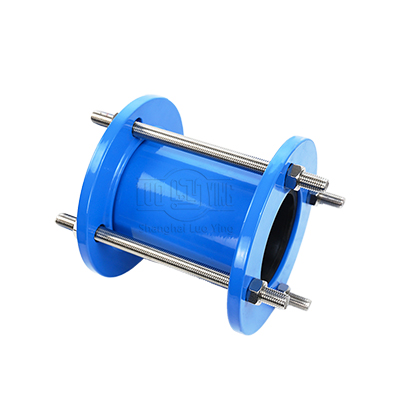

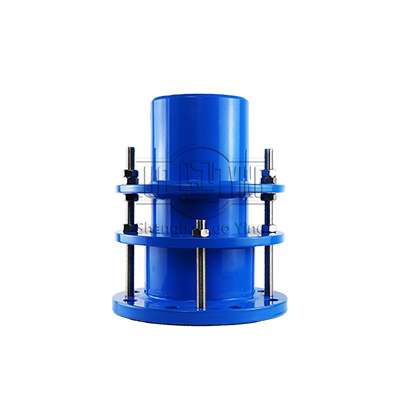

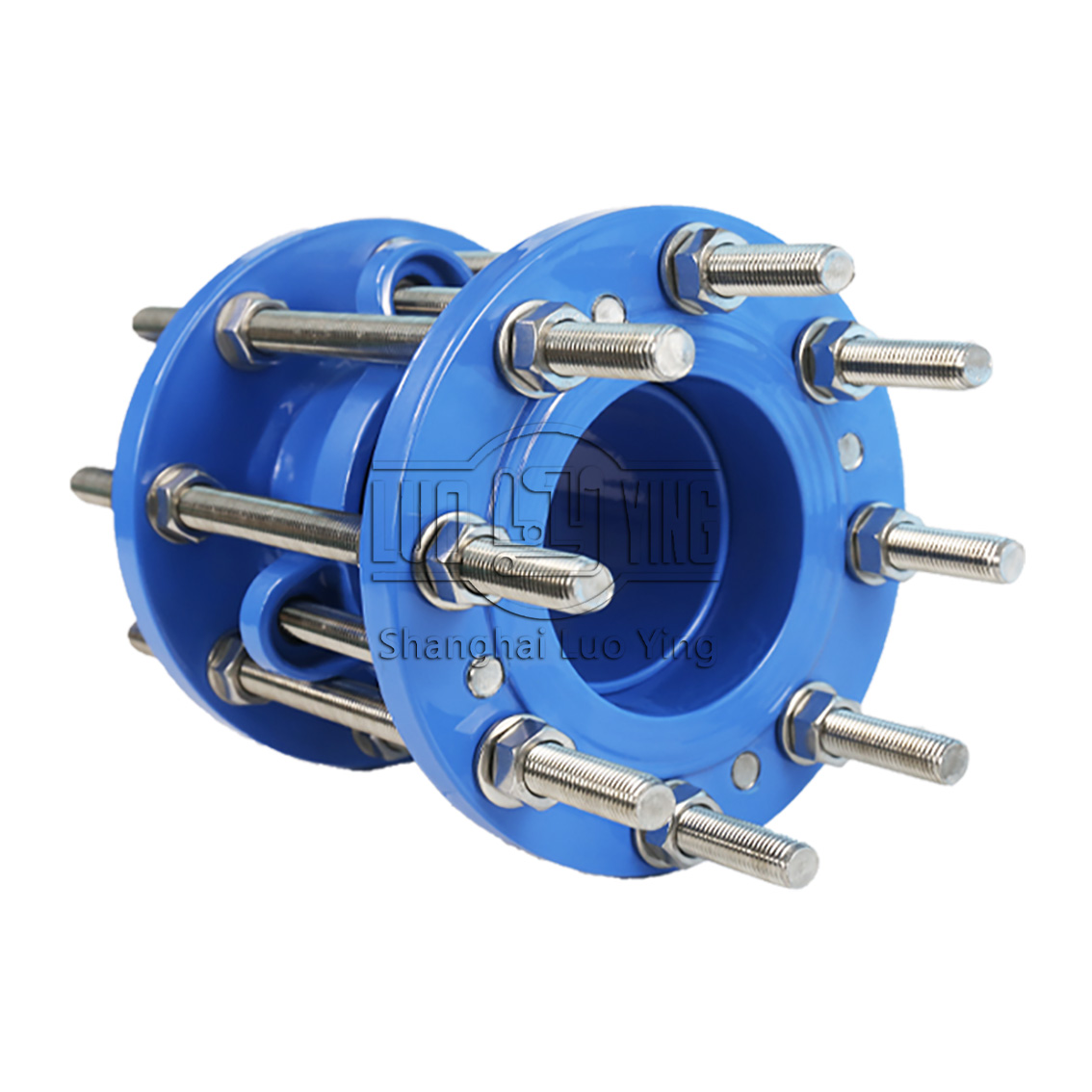

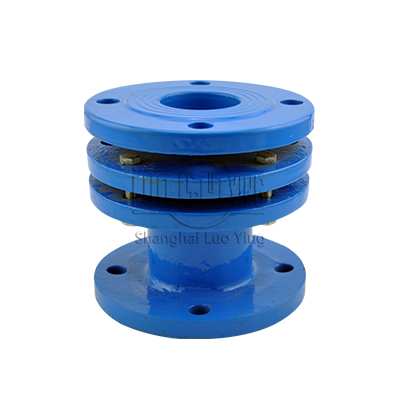

Dismantling joints play a decisive role in the design and layout of pipelines and valves. The dismantling joints are double flanged fittings that allow longitudinal adjustment in flanged pipe systems. Thanks to this adjustability of the dismantling joint, the valve can be fitted next to the dismantling joint, and the dismantling joint can be to set to the exact length required prior to being securely connected to flanges. Dismantling joints provide a simple method for installation and removal of flanged valves so also for subsequent maintenance. Typical applications include water treatment, sewage treatment, power generation and pumping stations. The dismantling joint guarantees fast installation and removal, thus contributing to increased efficiency and reducing site operations and down time.

Material:

Carbon Steel, ductile cast iron,stainless steel AISI 304L or AISI 316L

Bolts & nuts:

stainless steel bolts, zinc plated, upon request

Application:

Chemical, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire fighting, electric power, etc.

-

Brand

BrandLuoying

-

Size

SizeDN50-DN1500

-

Materials

Materials304L, 310, 316, and 316L.

-

Pressure

PressurePN 10,PN 16,PN 25

Product Range

-

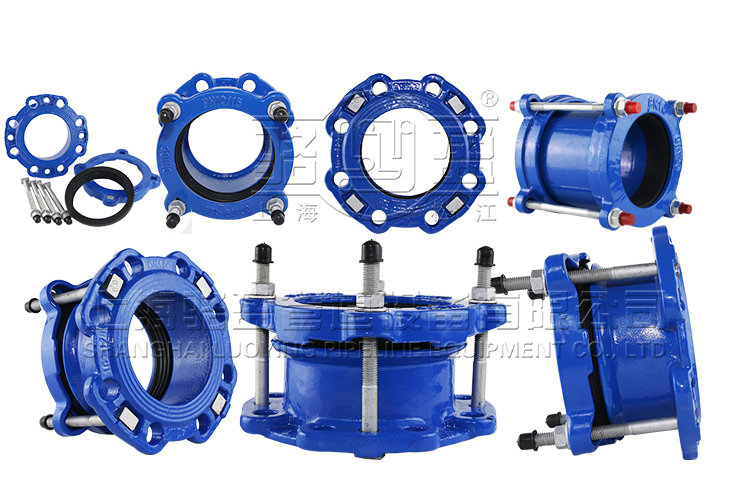

Carbon Steel Flange Adaptors

Flange adaptor couplings provide an effective means for inserting a flange into a pipeline for connection to another flanged component or valve. These adaptors are suitable for use in potable water; non-potable water and wastewater pipelines.

The most imView More

-

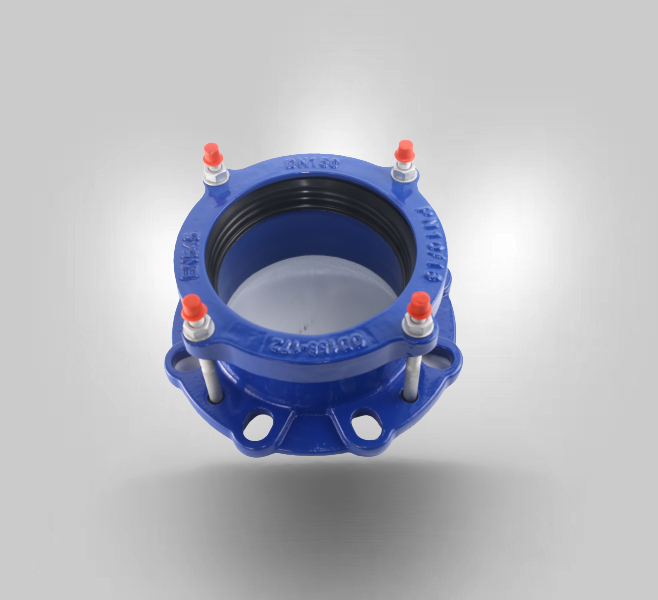

Ductile iron wide range flange adaptors

Flange adaptor couplings provide an effective means for inserting a flange into a pipeline for connection to another flanged component or valve. These adaptors are suitable for use in potable water; non-potable water and wastewater pipelines.

Working preView More

-

Ductile iron single range flange adapter

Universal straight fittings, stepped fittings and flange adapters for cast iron, ductile iron, steel, uPVC and asbestos cement pipes. Bolts and nuts with anti-friction coating provide long-lasting corrosion protection and allow for angular offsets of up t

View More

-

Flange adapters for ductile iron pipes

Tensile combination flanges for PE, PVC and ductile iron pipes, and non-tensile combination flanges for PVC, steel and ductile iron pipes. The design features a flexible positioning and chamfering of the pipe and a big angular deflection.

View More

-

PE-Special flange adaptor

The coupling consists of a sleeve that is placed between two end-rings. Between end-rings and sleeve, grip rings, press rings and gaskets are positioned. The end-rings are pressed onto the sleeve when the bolts are tightened. The rubber gasket, pressed by

View More

-

Ductile iron pe pipe single range flexible joint

The expansion joint is mainly composed of a body, a telescopic sleeve, a gland, a sealing ring and a bolt. The telescopic body, telescopic sleeve and gland are made of 16MnR, and the sealing ring is made of NBR sealing, which has good water tightness and

View More

-

Ductile iron hdpe pipe tube wide range flexible joint

Used to join two pipes or tube spigot ends

Designed to be connected to pipes of different materials, or for use with one material only, couplings are used to join two pipes or tube spigot ends.

There are several ranges of couplings available depending oView More

-

PE-Specialized flexible joint

Between end-rings and sleeve, grip rings, press rings and gaskets are positioned. The end-rings are pressed onto the sleeve when the bolts are tightened. The rubber gasket, pressed by the press ring and grip ring, then completely fills up the space betwee

View More

-

CS Heat pipe expanders

Thermodynamic compensator is mainly applied axial compensation, also has superior bending capacity, so I do not take into account the impact of sink pipes. Buried corrugated sleeve of compensation under the protection of housing and orientation compensati

View More

-

SSJB(AY) gland expansion joint

Dresser Coupling Joint on the basis of absorbing foreign advanced technology,combined with the actual needs of the research and development of a new pipeline connector,reasonable product structure design,reliable sealing performance;ends The socket connec

View More

-

VSSJA-1(BF)-type single flange limit expansion joint

Single Flange Dresser Coupling is formed by adding a limit device to the basic sleeve Type Expansion Joint and locked at maximum expansion by double nut.The pipeline can thus freely expand in certain limit. When maximum valve is reached,it will be limited

View More

-

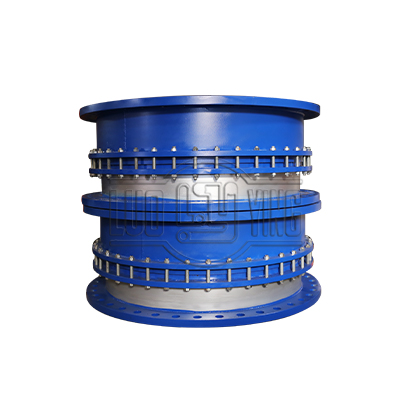

Large Flexible Dismantling Joint

Large Flexible Dismantling Joint is a new type of pipe connector researched and developed based on the facts of the development of our country and absorption of foreign advanced technology.The main structures are mde of short pipe flange,gland,sliding tub

View More

-

(VSSJAFG(C2F))Double flange force transfer joint Seller

Dismantling Joints Seller is designed to be the final closing piece in the pipe network,to ease the assembling and disassembling for later maintenance of a pump or valve.A standard adjusting range of 50mm on length and a small lateral and angular

View More

-

BY(SSJB-3) gland type loose end limit expansion joint

Covering Limited Telescopic Dismantling Joint is improved by adding the limited device on the basis of loose flexible rubber joint. Fit it with double nut at the maximum compensation volume, the product functions as limiting the position of rubber joint.

View More

-

RS Flexible Tube Retractor

Flexible sleeve expansion joint provides great convenience for water supply pipeline,water tower,water pump,water meter and valve to install and detach.It also can compensate the expansion or contraction caused by temperature change.

View More

-

VSSJA-2 (B2F) Double Flange Limit Expansion Joint

View More

-

Single Flange Dismantling Joints

Single flange transmission joint is used to connect Flange on the one side and weld pipe on the other,modulate the product's length in between.Screw down bolts after installation to integrate the structure and guarantee a ceitain shift which will facilit

View More

-

SSLW Strainer Retractor

Filter Expansion Joint, the lastest design for double uses, is the new coming pipeline facility with its compact structure, small size and light weight.1×1-50-600 horizontal screw-wing water meter without filter mesh, can block the water with the impurit

View More

Customized Products

Technical Notes

The Design Principle

Dismantling Joints play a decisive role in the design and layout of pipelines and valves. They are an essential aid during the installation and removal of pipe sections and valves. Without a dismantling joint offering longitudinal adjustment, it is almost impossible to insert a valve exactly into a pipe section. Thanks to this adjustability of the dismantling joint, the valve can be fitted next to the dismantling joint, and the dismantling joint can be to set to the exact length required prior to being securely connected to flanges.

The high-quality rubber gasket ensures that the system is always leaktight on tightening of the nuts.

Even if there are numerous versions of dismantling joints available for different applications, the basic principle is always the same:

The flange adaptor is located on one side of the dismantling joint. It is connected securely to the pipe or valve via the flange. Flange bore holes corresponding to the respective pressure rating or standard are available.

For the installation and removal of valves with longitudinal adjustment of maximum ± 25 mm, these two parts can be pushed against one another so that the dismantling joint can be inserted between the pipe sections or pipeline and valve.

Threaded tie-rods are used for the subsequent restraining and flange connection, depending on the type of dismantling joint used.

Advantage

Nsure that the hose meets the published levels.-

tolerances

The substantial adjustable travel of these products means the “face to face” tolerances of the equipment to be installed is no longer a concern. -

length

Used to facilitate the dismantling or the reassembly of a flanged piece of equipment on a pipeline, and adjustable in length with considerable travel. -

Simplify

Simplify maintenance operations because the connection is self-anchored and there is no need for concrete anchor blocks. -

eqipment

Compensates for axial displacement of eqipment in a pipe line during installation and dismantling as the telescopic action between the inner and outer flange bodies allows for longitudinal adjustment. -

easier

Makes placing joint rings between flanges easier, even those with inserts. -

additional

The additional flange also makes a time-saving preliminary installation.

Expansion joint accessories

Quality decides value-

Flange

Piping components can be bolted together between flanges. Flanges are used to connect pipes with each other, to valves, to fittings, and to specialty items such as strainers and pressure vessels. A cover plate can be connected to create a "blind flange" Flanges are joined by bolting, and sealing is often completed with the use of gaskets or other methods. Mechanical means to mitigate effects of leaks, like spray guards or specific spray flanges, may be included. Industries where flammable, volatile, toxic or corrosive substances are being processed have greater need of special protection at flanged connections. Flange guards can provide that added level of protection to ensure safety.

-

Covers

Fasteners are used for fastening and securing materials such as wood, metal, plastic, or concrete. They include nuts and bolts, threaded rods, structural bolts, machine screws, wedge anchors, washers, rivets, and more in a variety of types and sizes, including metric and inch.

-

Particulate barriers/purge connectors

In systems that have a media with significant particulate content (i.e. flash or catalyst), a barrier of ceramic fiber can be utilized to prevent corrosion and restricted bellows flexibility resulting from the accumulation of the particulate. Purge connectors may also be utilized to perform this same function. Internal liners must also be included in the design if the expansion joint includes purge connectors or particulate barriers.

-

Liners

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.