Concentric Reducing Rubber Joints

- [Name]:Reduced Rubber Joint Coupling

- [PN]: 0.6-2.5MPA

- [Medium]: Air, water, seawater, oil, slurry, weak acid, alkali, etc.

- [Material]: NR, NBR, CR, EPDM, PTFE etc.

- [Certification]: ISO9001:2008:

- [Products]: Reduced Rubber Coupling、Reduced Rubber Joint

Overview

Elastomeric expansion joints, unlike piping expansion joints of other materials, can be manufactured with concentric or eccentric tapers, transitioning from a larger diameter on one side and smaller on the other. These expansion joints are normally hand-built on a mandrel and not of the molded variety. The low volume requirements and nonstandard lengths do not support the high cost of mold tooling.

Before moving forward, it is important to define and clarify the difference between concentric and eccentric tapered reducers:

The concentric design is where the center of each flange is concentric or in line with each other

The eccentric design is where the center of each flange is eccentric or offset with each other

Features

Reduced Rubber Joint Coupling:

(1) Economy: Compared with the systems of mechanic stretching and material damping, Reduced Rubber Coupling has the advantages of little space covering, light weight, easy assembly and disassembly, labor saving and low cost. Its smooth inner wall can reduce flow resistance. It has good water tightness, so there is no need of gasket during the installation. It has wide application, large temperature-resistance scope and long working life. (This product can be used for 20 years if it is used indoors.)

(2) Displacement: Flange is free from pipe decentraction and imbalance. Its good flexibility allows compression, extension, distortion, deflection of vertical displacement, etc. which can prevent the pipeline from damage of deformation and foundation settlement arising from expansion caused by heat and contraction caused by cold.

(3) Shock and noise absorption: The large damping of rubber sphere can effectively buffer and isolate vibration, control and reduce mechanical vibration, and absorb fluid impact noise. The reasonable installation between vibrating machine and metal pipe can decrease structure-borne noise by 15-25 decibels.

(4) Pressure resistance: The multilayered sphere structure can especially endure internal pressure, withstand strong blasting force and impact, and prevent deformation from external pressure. There are many pressure standards on work piece.

(5) Reducibility: After external force compressed, the Reduced Rubber Joint can recover to original state when this force is removed.

(6) Wide application: Different rubber material and formula can make product possess different resistance to heat, oil, corrosion, age, abrasion and ozone.

Specification

| Model Item | JDX(DN50~300) | JDX(DN350~600) | Note: |

| Working pressure (Mpa) | 1 | 0.6 | If the medium is oil, acid,alkali material,special requirements for working temperature,please write and provide drawings and samples when placing an order. |

| Explosion pressure (Mpa) | 1.8 | 1.5 | |

| Vacuum(Kpa) | 86.7 | 53.3 | |

| Applicable Temperature | -20°C-+115°C(-30°C-250°C under special conditions) | ||

| Applicable Medium | Air,compressed air,water,sea water,oil,acid,alkali,and so on | ||

| Note:the material of main component is same with that of JGD-A type | |||

Technical parameter:

| DN×DN | Length(mm) | Axial displacement(mm) | Horizontal displacemen(mm) | Angular deflection(a1+a2) | Note | |

| Extension | Compression | |||||

| 80×50 | 180 | 20 | 30 | 45 | 35 | The coupling flanges according to National Drainage S311 Standard |

| 100×80 | 180 | 20 | 30 | 45 | 35 | |

| 150×80 | 190 | 20 | 30 | 45 | 35 | |

| 150×100 | 200 | 22 | 30 | 45 | 35 | |

| 200×100 | 200 | 22 | 30 | 45 | 35 | |

| 200×150 | 200 | 22 | 30 | 40 | 35 | |

| 250×200 | 200 | 25 | 35 | 40 | 30 | |

| 300×200 | 220 | 25 | 35 | 40 | 30 | |

| 300×250 | 220 | 25 | 35 | 40 | 30 | |

| 350×200 | 220 | 25 | 35 | 40 | 30 | |

| 350×300 | 220 | 25 | 38 | 35 | 30 | |

| 400×350 | 220 | 25 | 38 | 35 | 30 | |

| 500×400 | 230 | 28 | 38 | 35 | 26 | |

| 600×400 | 240 | 28 | 38 | 35 | 26 | |

| 600×500 | 240 | 28 | 38 | 35 | 26 | |

Related Products

-

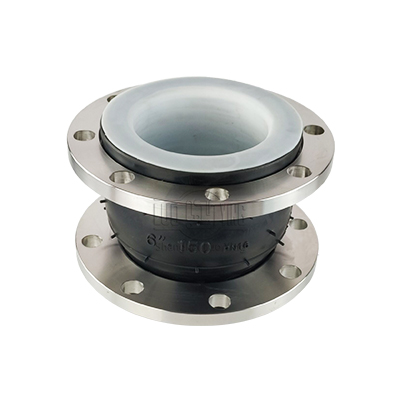

PTFE lined rubber joint

PTFE provides added resistance to aggressive chemicals and temperatures versus a traditional rubber tube expansion joints.

View More

-

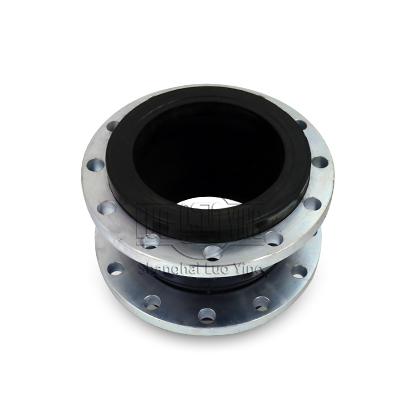

THREADED UNION

Rubber joint has the characteristics of good sealing, light weighting, easy to fix and maintain, also has long working expecting,but please keep far away from sharp metal in order to avoid breaking the rubber body.

View More

-

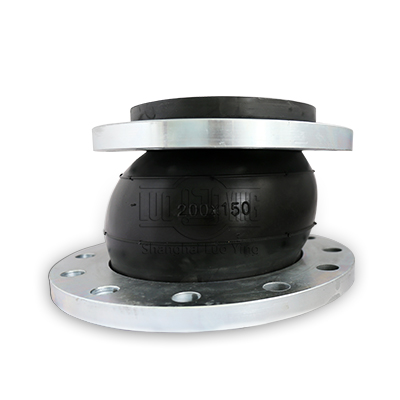

Double sphere rubber joint

Double Ball Rubber Joint, is mainly the use of rubber unique properties, such as high flexibility, high air tightness, chemical resistance and radiation resistance, high strength, strong cold stability bias ply polyester composite Hou contrast, high press

View More

-

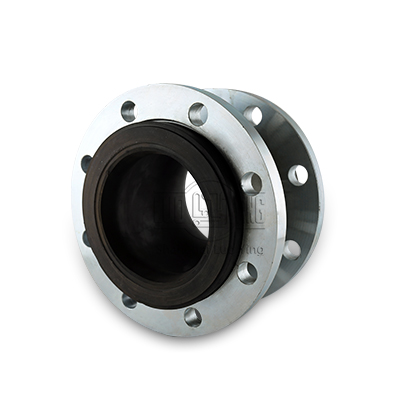

Flanged single sphere expansion

Flexible rubber joint is also called shock absorber, pipe shock absorber, shock absorber larynx, flexible rubber joint, rubber soft connection, soft connector. Flexible single ball rubber joint is flexible coupling of metal pipe, composed by inner layer,

View More

-

WTX rubber flexible elbow

Flexible rubber joint is also called shock absorber,pipe shock absorber,shock proof box and soft joint ,and so on. It is a pipe joint of high-flexibility,high-gas tightness,resistance to medium and climate.It has such functions as following.

View More

-

Eccentric rubber coupling

Reducing flexible rubber joint is widely used in the field of chemical industry, construction, supply water, sewage drainage, petroleum, light and heavy industry, sanitation, plumbing, electricity and other fundamental engineering.

View More

-

JGD-A double sphere rubber joint

Rubber joints, also known as flexible rubber joints, flexible rubber joints, soft rubber joints, shock absorber, (shock absorbers throat), rubber shock absorbers, rubber expansion joints and so on. The product consists of inner and outer layers of plastic

View More

-

DIN Standard Single Arch rubber

Single Arch Rubber Joint are reinforced by a fabric and flat-shaped pieces of rubber wood joints, loose set of metal flange or threaded pipe flanges, used in pipe vibration noise reduction, compensation displacement connector. It is a highly flexible, hig

View More

-

Single Ball Flexible Pipe Rubber

Rubber joints are also called rubber hose flexible joints, flexible rubber joints, rubber flexible joints, bendable rubber joints, high pressure rubber joints, rubber shock absorbers, compensators and so on. According to the connection method, there are 3

View More

-

Threaded rubber expansion bellow

Rubber joint has the characteristics of good sealing, light weighting, easy to fix and maintain, also has long working expecting,but please keep far away from sharp metal in order to avoid breaking the rubber body.

View More

Inquiry

Welcome to visit our website. If you need our products please write down any questions, we will reply as soon as possible.