Valve

Application:

Valves are found in virtually every industrial process, including water and sewage processing, mining, power generation, processing of oil, gas and petroleum, food manufacturing, chemical and plastic manufacturing and many other fields.

People in developed nations use valves in their daily lives, including plumbing valves, such as taps for tap water, gas control valves on cookers, small valves fitted to washing machines and dishwashers, safety devices fitted to hot water systems, and poppet valves in car engines.

In nature there are valves, for example one-way valves in veins controlling the blood circulation, and heart valves controlling the flow of blood in the chambers of the heart and maintaining the correct pumping action.

Valves may be operated manually, either by a handle, lever, pedal or wheel. Valves may also be automatic, driven by changes in pressure, temperature, or flow. These changes may act upon a diaphragm or a piston which in turn activates the valve, examples of this type of valve found commonly are safety valves fitted to hot water systems or boilers.

More complex control systems using valves requiring automatic control based on an external input (i.e., regulating flow through a pipe to a changing set point) require an actuator. An actuator will stroke the valve depending on its input and set-up, allowing the valve to be positioned accurately, and allowing control over a variety of requirements.

Variation

Valves vary widely in form and application. Sizes[ambiguous] typically range from 0.1 mm to 60 cm. Special valves can have a diameter exceeding 5 meters.[which?] Valve costs range from simple inexpensive disposable valves to specialized valves which cost thousands of US dollars per inch of the diameter of the valve.

Disposable valves may be found in common household items including mini-pump dispensers and aerosol cans.

A common use of the term valve refers to the poppet valves found in the vast majority of modern internal combustion engines such as those in most fossil fuel powered vehicles which are used to control the intake of the fuel-air mixture and allow exhaust gas venting.

-

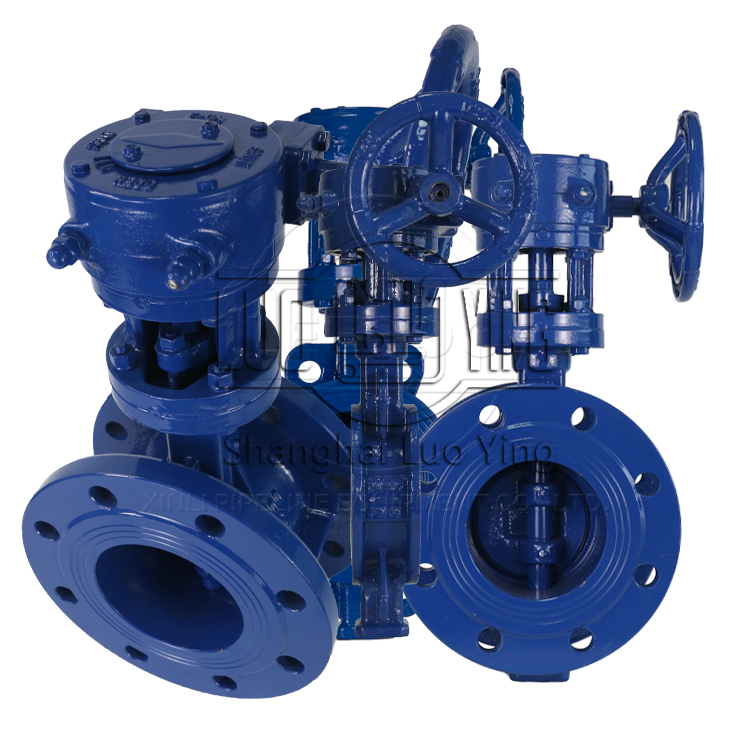

Brand

BrandLUOYING

-

Size

SizeDN15-DN1200

-

Temp

Temp-20°C to 250°C

-

Pressure

Pressure16bar

Product Range

-

Stainless steel 316 shut-off valve

Stainless steel 316 globe valves are commonly used shut-off/regulating valves in industrial piping systems. Their core advantages and features stem from the combination of the excellent performance of 316 stainless steel and the functional characteristics

View More

-

Stainless steel flanged ball valve

Stainless steel flanged ball valves can be tightly closed with a 90-degree rotation and minimal torque. The fully symmetrical valve body cavity provides a low-resistance, straight-through flow path for the medium.

View More

-

Open stem hard seal gate valve

Gate valve is a full bore valve. Thanks to the metal seat, those valves are able to respond to specific operating conditions (high pressure, high temperatures). Its production is varied (cast iron, steel, stainless steel, duplex, etc.), it can therefore b

View More

-

Open stem soft seal gate valve

Gate valve is a full bore valve. Thanks to the metal seat, those valves are able to respond to specific operating conditions (high pressure, high temperatures). The wedge is fully vulcanized with drinking water approved EPDM rubber compound. It features a

View More

-

Concealed rod hard seal gate valve

Gate valve is a full bore valve. Thanks to the metal seat, those valves are able to respond to specific operating conditions (high pressure, high temperatures). Its production is varied (cast iron, steel, stainless steel, duplex, etc.), it can therefore b

View More

-

Concealed rod soft seal gate valve

When this valve with bi-directional flow is fully open, the gate and pipeline diameter are the same and there is very low head loss.

View More

-

Silent check valve

The Silent Check Valve is the preferred choice in applications where silent operation and cost are of major concern. Its short linear stroke and spring return action combine to close the valve prior to flow reversal which effectively eliminates the shock

View More

-

Rubber flap check valve

Rubber Flapper Swing Check Valves feature a unique, simple design with only one moving part. The flapper does not swing from a hinge pin; it simply flexes open. The seat is on a 45° angle. The flapper travels 35° from open to closed, usually before column

View More

-

Ball check valve

The ball check valve is suitable for use in polluted media as the ball shaped valve prevents the built up of dirt. The valve is for maintenance easy accessible through a large opening. The ball check valve may be used in waste water treatment, in power pl

View More

-

Worm Gear Operated Wafer Bufferfly Valve

The rubber is injection moulded directly on the valve body forming a permanent bond. Consequently, there is no risk of deformation or dislocation of the liner making the valves suitable under vacuum conditions. The combination of the profiled disc edge an

View More

-

Double flanged butterfly valve with handwheel

Suitable for mounting between flanges and can be used in many general applications such as in water distribution, water treatment, dams, power plants and in many other. The valve can be used as a stopper, a tap for discharging at the end of the pipeline,

View More

-

Wafer type butterfly valve with handle

Butterfly Valve with hard phenolic seat, pin or splined connection between disc and stem, both wafer and lug style. Suitable for most general purpose applications.The valve can be used for both ‘open/close’ and for flow control operations.

View More

-

Wafer type butterfly valve with gearbox

Butterfly valves are designed for cost-effective isolation of pipelines and are suitable for pressure and non-pressure water and industrial applications. The quarter turn disc can be actuated by lever or gearbox and is available in wafer, lugged or flange

View More

-

Y type pipe filter

Y type pipe filter is a kind of device used for conveying medium, mainly installed in entrance gate of hydraulic control valves, pressure reducing valve, pressure relief valve, etc.

View More

Technical Notes

Valves vary widely in form and application

Many valves are controlled manually with a handle attached to the stem. If the handle is turned ninety degrees between operating positions, the valve is called a quarter-turn valve. Butterfly, ball valves, and plug valves are often quarter-turn valves. If the handle is circular with the stem as the axis of rotation in the center of the circle, then the handle is called a handwheel. Valves can also be controlled by actuators attached to the stem. They can be electromechanical actuators such as an electric motor or solenoid, pneumatic actuators which are controlled by air pressure, or hydraulic actuators which are controlled by the pressure of a liquid such as oil or water. Actuators can be used for the purposes of automatic control such as in washing machine cycles, remote control such as the use of a centralised control room, or because manual control is too difficult such as when the valve is very large. Pneumatic actuators and hydraulic actuators need pressurised air or liquid lines to supply the actuator: an inlet line and an outlet line. Pilot valves are valves which are used to control other valves. Pilot valves in the actuator lines control the supply of air or liquid going to the actuators.

The fill valve in a toilet water tank is a liquid level-actuated valve. When a high water level is reached, a mechanism shuts the valve which fills the tank.

In some valve designs, the pressure of the flow fluid itself or pressure difference of the flow fluid between the ports automatically controls flow through the valve.

Other considerations

TValves are typically rated for maximum temperature and pressure by the manufacturer. The wetted materials in a valve are usually identified also. Some valves rated at very high pressures are available. When a designer, engineer, or user decides to use a valve for an application, he/she should ensure the rated maximum temperature and pressure are never exceeded and that the wetted materials are compatible with the fluid the valve interior is exposed to. In Europe, valve design and pressure ratings are subject to statutory regulation under the Pressure Equipment Directive 97/23/EC (PED).

Some fluid system designs, especially in chemical or power plants, are schematically represented in piping and instrumentation diagrams. In such diagrams, different types of valves are represented by certain symbols.

Valves in good condition should be leak-free. However, valves may eventually wear out from use and develop a leak, either between the inside and outside of the valve or, when the valve is shut to stop flow, between the disc and the seat. A particle trapped between the seat and disc could also cause such leakage.

Advantage

Nsure that the hose meets the published levels.-

loss

Gate valves contain very low friction loss. -

full-closing

Globe valves throttling, the full-closing characteristic is good.The opening-closing time is shorter. -

flexibility

Ball valves have multi-way design flexibility.They open and close quickly. -

maintenance

Butterfly valves are very accurate, which makes them advantageous in industrial applications.They are quite reliable and require very little maintenance. -

backup

Check valves prevent backflow.They can sustain pressure. Check valves serve as backup system. -

features

Industrial valves are devices that are used to regulate liquids, gases, and slurries. The flow of liquids or gases can be controlled using these valves.