Acid and alkali corrosion resistant EPDM rubber joint role

Dec-22-23

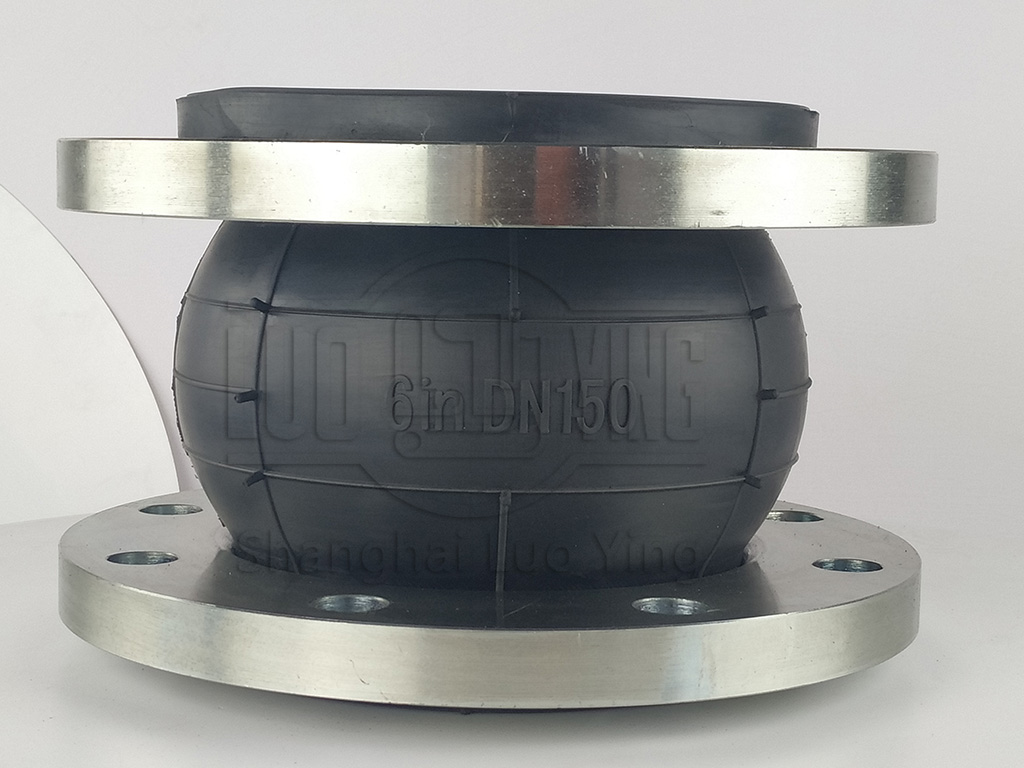

The sphere of rubber joint is composed of inner rubber layer, reinforcement layer with multiple layers of scraped rubber nylon cord fabric, outer rubber layer compound rubber tube. Depending on the medium, the rubber materials used are different, including natural rubber, butyl rubber, butyl rubber, nitrile rubber, EPDM rubber, neoprene rubber, silicone rubber, fluorine rubber and so on. They have heat resistance, acid resistance, alkali resistance, corrosion resistance, wear resistance, oil resistance and other functions.EPDM rubber is a kind of engineering plastic, synthetic rubber and elastomer with excellent performance, which is widely used in transportation, construction, energy, medical and health care, industry, agriculture, light industry and other industries and fields. It has high elasticity, good wear resistance, good chemical resistance, excellent aging resistance, good impact resistance and excellent aging resistance. EPDM rubber has excellent physical and mechanical properties, heat resistance aging performance, excellent flame retardancy, good radiation resistance, low temperature will not produce deformation, and has excellent electrical insulation, high electrical insulation and good anti-static properties. It is especially suitable for electric and electronic industrial instruments and meters, precision mechanical equipment and industrial pipelines, etc. Has excellent anti-aging properties.

Acid and alkali corrosion resistant EPDM rubber joints also have anti-aging properties. Corrosion of alkaline media, stainless steel corrosion rate is faster than stainless steel. Therefore, the choice of stainless steel is an important factor for acid-resistant and high-temperature resistant rubber hose. Abrasion and high temperature resistant rubber hose has good temperature resistance, good chemical resistance, heat fatigue resistance, radiation resistance, etc.. It has high elasticity and low coefficient of thermal expansion. It will not be damaged and aged when the temperature of the conveyed medium is higher than 130℃. For wear-resistant and high temperature resistant rubber hose, it has poor heat resistance because the density of the internal layer is very small. When the temperature rises to 60℃, it will burn off and fall off. However, it can be kept for a long time without cracking and peeling under low temperature conditions. So the pipe has good anti-aging ability in the cold area.