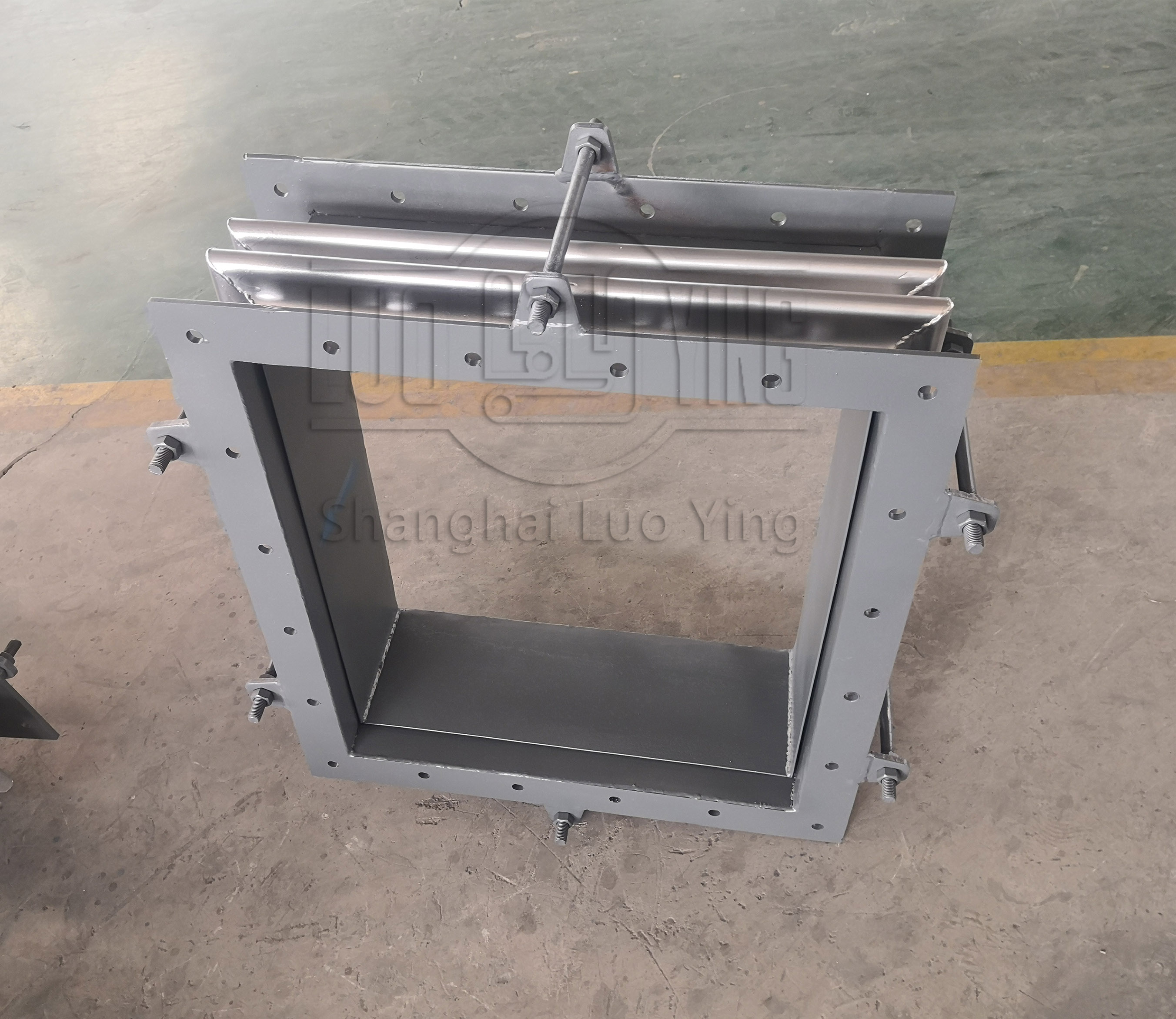

Square compensator in the installation of the need to pay attention to the problem

May-23-20

Square compensator in the installation of the need to pay attention to the problemAfter the square compensator is manufactured, its centerline dimensions should conform to the dimensional requirements listed in the standard series. The elbow wall surface should not have cracks, metal delamination, overburning and other defects. The main use of the square compensator is to compensate for damage caused by high temperature of the pipeline. Mostly used for pipeline through the structure expansion joints, earthquake gaps, settlement gaps at the laying of compensation. In fact, as long as the following points are noted before installation, there will be no problems in the installation process.

2 . For vertical installation, if the conveyed medium is liquid, a drainage device should be installed at the low point of the expander. Both sides of the expander bracket is best set at 0.5-1m from the starting point of the expander elbow bend, bracket activity bracket should not be set guide bracket.

3 . Install the expander, in order to reduce the thermal stress and improve the thermal compensation capacity, the expander must be pre-stretched, the pipeline conveying hot media need to be cold drawn, the pipeline conveying cold media need to be cold drawn and cold pressed. Pre-tensioning or pre-pressure of the pipe should be carried out after the pipe between the two fixed brackets is installed and firmly connected to the fixed brackets. At the same time stretch or compress the double arms of the draw-off.

4 . The maximum distance of the retractor is set for the branch section of the pipe.

5 . Pre-stretching of the square pipe expander. The square expander should be pre-stretched before installation. One stretching method is to open the square pipe expander with a jack, and the other is the commonly used pipe puller method.

6 . Pre-stretch welding joint should be selected at 2-2.5m from the beginning of the expansion device bending, should not be too close to the expansion device. Before cold-drawing should check whether the cold-drawing weld gap is in line with the cold-drawing value.

7 . When installed horizontally, it should be consistent with the slope of the pipeline; when installed vertically, an exhaust valve should be set at the high place and a drain valve at the low place.

8 . Bending of the square pipe expander should be made by bending the whole pipe. If the interface is required, the interface should be located in the middle of the straight arm.

9 . The first bracket on both sides of the compensator should be set at 0.5-lm from the beginning of the compensator elbow bend, the bracket is suitable for the activity bracket.

The installation of the compensator should be carried out after the other pipes between the two fixed brackets have been installed. The number and setting of the square expander is determined by the designer taking into account engineering design, calculation parameters and construction requirements. There are corresponding technical requirements for the number and type of expanders in the engineering design. The pipe winding column is determined only according to the actual situation at the construction site. The winding column can be one or more. The distance between the U-shaped elbows of the winding column may be more than 10 meters or more than 20 meters. From the installation point of view, only the strength and sealing of the connection around the column are required, nothing else. The production and installation requirements for square compensators far exceed those for bends.